Preparation method of silk fiber-based patterned semiconductor polymer film

A technology of polymer film and silk fiber, applied in the field of polymer patterning preparation, can solve the problems of soft template preparation process conditions, soft template easily affected by organic solvents, complicated hard template preparation process, etc. The effect of reducing the difficulty of preparation, low cost and reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

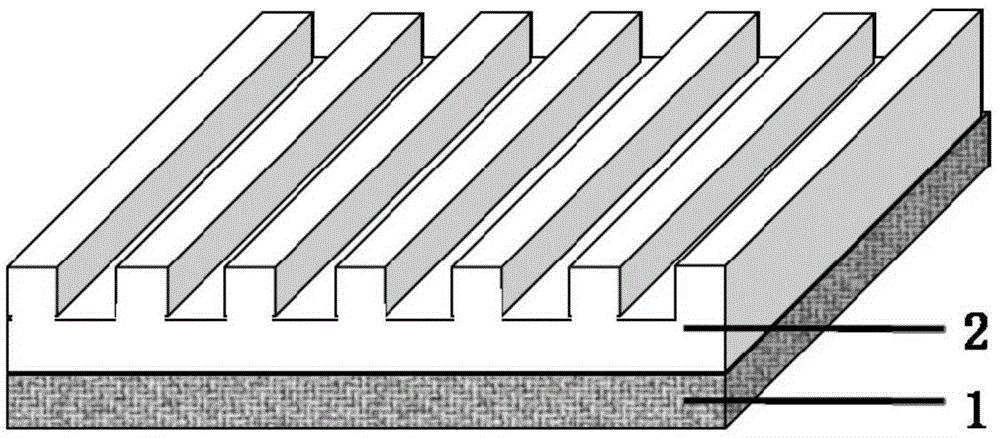

[0033] ①Using the existing electron beam exposure technology to process the surface of the photoresist film to prepare the micro-nano pattern of the line structure, the characteristic structure size is 250 nanometers, in figure 1 Among them, 1 represents the silicon substrate S1 which only serves as a substrate support, and 2 represents the photoresist PMMA (an existing commercially available product).

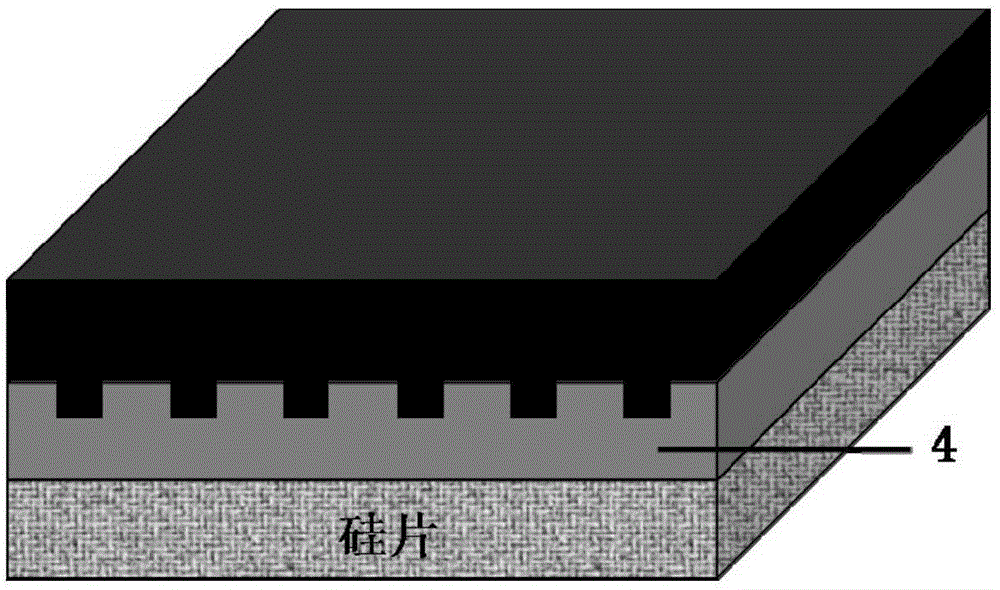

[0034] ② Evenly coat the uncrosslinked PDMS solution (commercially available product) on the surface of the photoresist film with micro-nano structure, place the whole in a vacuum drying oven, and conduct heating and crosslinking. The crosslinking conditions are: vacuum degree 0.09 MPa, the heating temperature is 65 degrees Celsius, and the crosslinking time is 30 minutes; after crosslinking, the PDMS soft template is uniformly removed from the surface of the photoresist, so that the surface of the PDMS soft template has a micro-nano structure complementary to the pattern struc...

Embodiment 2

[0039] ①Using electron beam exposure technology to prepare micro-nano pattern of line structure on the surface of photoresist film, the characteristic structure size is 200 nanometers, in figure 1 Among them, 1 represents the silicon substrate S1 which only serves as a substrate support, and 2 represents the photoresist PMMA.

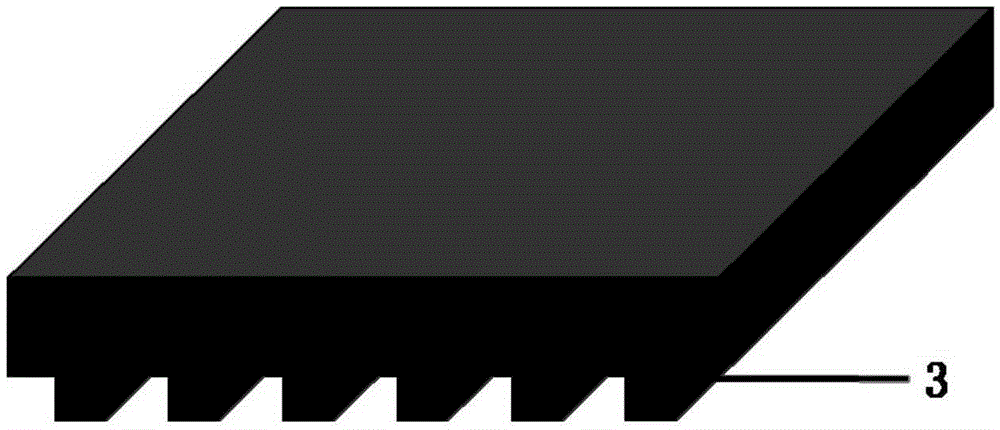

[0040] ② Evenly coat the uncrosslinked PDMS solution on the surface of the photoresist film with micro-nano structure, place the whole in a vacuum drying oven, and heat and crosslink. After the sufficient crosslinking treatment is completed, the PDMS soft template It is uniformly removed from the surface of the photoresist, so that the surface of the PDMS soft template has a complementary micro-nano structure pattern on the surface of the photoresist, such as figure 2 As shown, 3 represents the PDMS organic material.

[0041] ③ Preparation of silk fiber aqueous solution: put natural silk into 0.06% sodium carbonate aqueous solution, degumming treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com