A kind of preparation method of molecular sieve-based scr catalyst

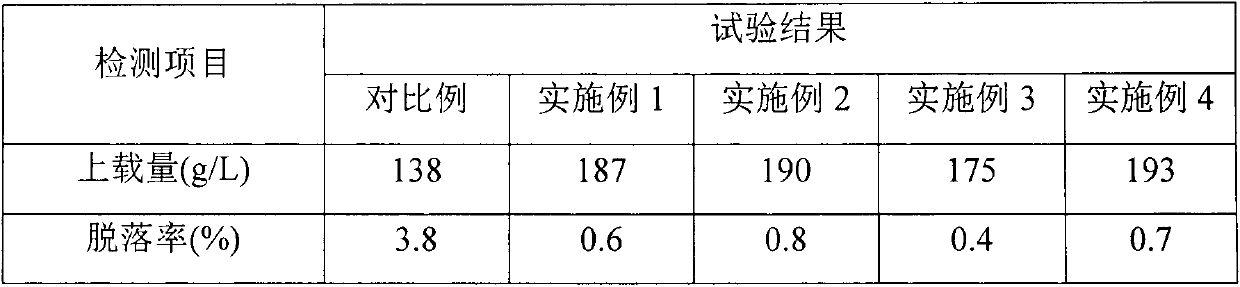

An SCR catalyst, molecular sieve-based technology, applied in the field of automobile exhaust purification and diesel engine exhaust catalytic purification, can solve the problems of low catalytic coating loading and easy to fall off, and achieves increased coating loading, low peeling rate, and improved adhesion. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under stirring conditions, 7.0g of ammonia water was added to 180.0g of deionized water, 10.0g of zirconium nitrate was added dropwise to the above ammonia solution, and then 4.0g of oxalic acid was added to obtain translucent zirconium oxalate sol; 50.0g of aluminum isopropoxide Add the zirconium oxalate sol prepared in the above steps, add nitric acid to adjust the pH value to 3.0, heat the above mixed solution to 60°C, and stir for 1 h to obtain Al 2 o 3 -ZrO 2 Composite sol; add 120.0g ZSM-5 molecular sieve and 20.0g deionized water to the composite sol prepared in the above steps and mix, ball mill for 6 hours to obtain the coating slurry; impregnate the honeycomb ceramics into the above coating slurry, take out Finally, blow off the remaining slurry in the channels, dry at 100°C for 5 hours, repeat the impregnation and drying three times, and finally bake at 500°C for 3 hours to obtain the selective reduction (SCR) catalyst.

Embodiment 2

[0024] Under stirring conditions, 6.7g of ammonia water was added to 130.0g of deionized water, 10.0g of zirconium nitrate was added dropwise to the above ammonia solution, and then 3.3g of oxalic acid was added to obtain translucent zirconium oxalate sol; 50.0g of aluminum isopropoxide Add the zirconium oxalate sol prepared in the above steps, add nitric acid to adjust the pH value to 3.0, heat the above mixed solution to 60°C, and stir for 1 h to obtain Al 2 o 3 -ZrO 2 Composite sol; 90.0g Beta molecular sieve and 20.0g deionized water were added to the composite sol prepared in the above steps and mixed, ball milled for 8 hours to obtain coating slurry; the honeycomb ceramics were impregnated into the above coating slurry, taken out and blown Dried at 120°C for 4 hours to get rid of the remaining slurry in the pores, repeated impregnation and drying three times, and finally baked at 550°C for 2 hours to obtain a selective reduction (SCR) catalyst.

Embodiment 3

[0026] Under stirring conditions, 7.2g of ammonia water was added to 160.0g of deionized water, 10.0g of zirconium nitrate was added dropwise to the above ammonia solution, and 4.5g of oxalic acid was added to obtain translucent zirconium oxalate sol; 55.0g of aluminum isopropoxide Add to the zirconium oxalate sol prepared in the above steps, add nitric acid to adjust the pH value to 3.5, heat the above mixed solution to 70°C, and stir for 1.5h to obtain Al 2 o 3 -ZrO 2 Composite sol; add 108.0g Y-type molecular sieve and 20.0g deionized water to the composite sol prepared in the above steps and mix, ball mill for 10 hours to obtain the coating slurry; impregnate the honeycomb ceramics into the above coating slurry, take it out Blow out the remaining slurry in the channels, dry at 130°C for 3 hours, repeat impregnation and drying three times, and finally bake at 550°C for 2 hours to obtain a selective reduction (SCR) catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com