Up-to-standard discharge treatment technology of drilling wastewater from oil and gas fields

A technology of drilling wastewater and treatment process, which is applied in mining wastewater treatment, water/sewage treatment, special compound water treatment, etc. It can solve the problems of unsuitable wastewater, difficult engineering application, poor biodegradability, etc., and reduce the content of suspended solids , Realize the effect of skid-mounted installation and enhance the coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

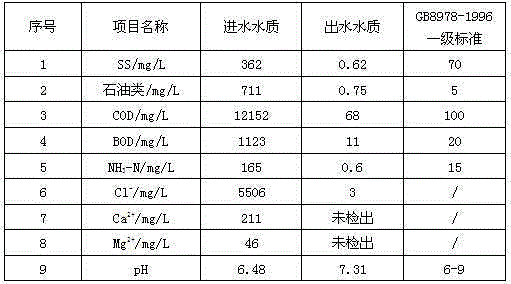

Embodiment 1

[0032] A treatment process for discharge of oil and gas field drilling wastewater up to standard, comprising the following steps:

[0033] (1) Water quality adjustment treatment, collect the wastewater to be treated to the adjustment tank, and add acid to adjust the pH value of the wastewater to 3.

[0034] (2) Oxidation treatment, the wastewater effluent after mixing and adjusting the pH in the adjustment tank in step (1) is sent to the Fenton advanced oxidation reactor, and Fenton’s reagent is added to the wastewater. Fenton’s reagent includes FeSO4 and H2O2, and the added The mass ratio of FeSO4 and H2O2 is 1:2. The Fenton Advanced Oxidation Reactor is composed of two-stage reactors. The first-stage reactor mainly destroys macromolecular organic matter (surfactant, etc.), breaks the chain into small-molecular organic matter, breaks the emulsion and reduces thickening, and partially removes organic matter at the same time; The reactor mainly degrades the small molecular org...

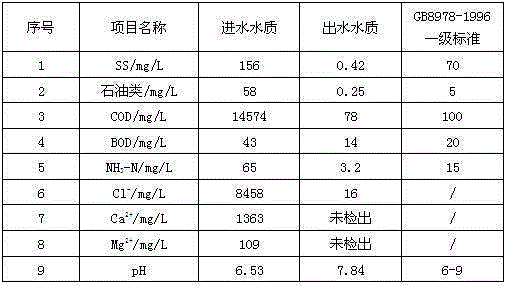

Embodiment 2

[0048] A treatment process for discharge of oil and gas field drilling wastewater up to standard, comprising the following steps:

[0049] (1) Water quality adjustment treatment, collect the wastewater to be treated into the adjustment tank, and add acid to adjust the pH value of the wastewater to 3.5.

[0050] (2) Oxidation treatment, the wastewater effluent after mixing and adjusting the pH in the adjustment tank in step (1) is sent to the Fenton advanced oxidation reactor, and Fenton’s reagent is added to the wastewater. Fenton’s reagent includes FeSO4 and H2O2, and the added The mass ratio of FeSO4 and H2O2 is 1:2. The Fenton Advanced Oxidation Reactor is composed of two-stage reactors. The first-stage reactor mainly destroys macromolecular organic matter (surfactant, etc.), breaks the chain into small-molecular organic matter, breaks the emulsion and reduces thickening, and partially removes organic matter at the same time; The reactor mainly degrades the small molecular...

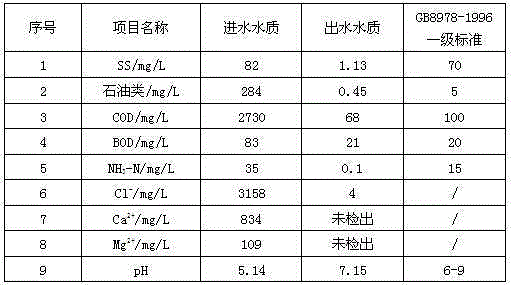

Embodiment 3

[0058] A treatment process for discharge of oil and gas field drilling wastewater up to standard, comprising the following steps:

[0059] (1) Water quality adjustment treatment, collect the wastewater to be treated to the adjustment tank, and add acid to adjust the pH value of the wastewater to 4.

[0060] (2) Oxidation treatment, the wastewater effluent after mixing and adjusting the pH in the adjustment tank in step (1) is sent to the Fenton advanced oxidation reactor, and Fenton’s reagent is added to the wastewater. Fenton’s reagent includes FeSO4 and H2O2, and the added The mass ratio of FeSO4 and H2O2 is 1:2. The Fenton Advanced Oxidation Reactor is composed of two-stage reactors. The first-stage reactor mainly destroys macromolecular organic matter (surfactant, etc.), breaks the chain into small-molecular organic matter, breaks the emulsion and reduces thickening, and partially removes organic matter at the same time; The reactor mainly degrades the small molecular org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com