Laser repairing and strengthening composite treating method for damage cutter of shearing equipment

A composite treatment and laser repair technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of peeling, secondary damage, low bonding strength, etc., to improve hardness and wear resistance, improve fatigue resistance, improve The effect of comprehensive mechanical properties

Inactive Publication Date: 2016-03-02

JIANGSU WANLI MACHINERY +1

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, using surface repair materials to repair under strong laser light, on the one hand, the bonding strength between the repair materials and the base material is low, and may fall off in subsequent use, and even cause secondary damage. On the other hand, this method affects the hardness of the repaired materials. Small impact, basically maintain the hardness of raw materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0033] T8 steel shearing equipment tool (chemical composition: C0.75~0.84; Si≤0.35; Mn≤0.4; S≤0.030; P≤0.035), hardness: annealing≤187HB; indentation diameter≥4.40mm; quenching≥62HRC.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

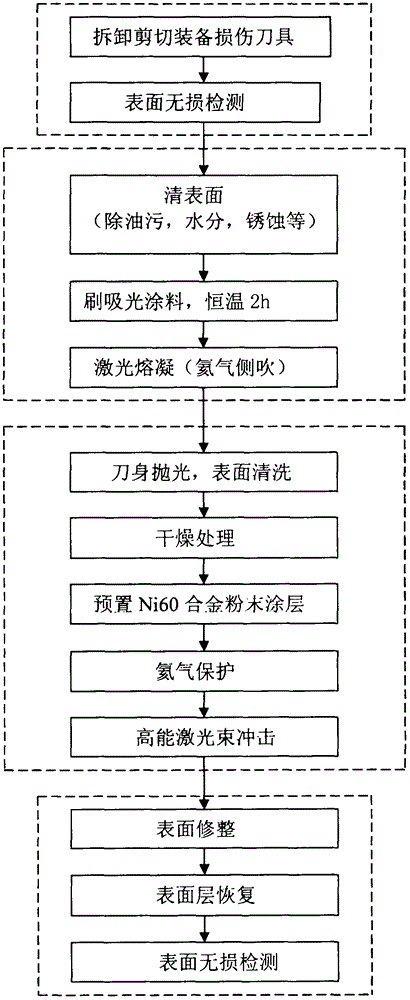

The invention relates to a laser repairing and strengthening composite treating method for a damage cutter of shearing equipment, and relates to the technical field of machine manufacturing and material treating machining application. The composite treating method includes the steps that surface nondestructive testing is carried out on a cutter of the shearing equipment firstly; then laser fusion repairing is carried out on a defect part of the damage cutter, and meanwhile helium is led in to protect a laser fusion part; and polishing and purifying are carried out on the laser fusion part of the cutter after the laser fusion repairing is carried out, Ni60 alloy powder is pre-arranged on the surface of the cutter, a base body surface layer of the cutter is heated and fused through high-energy laser beams, rapid solidification is carried out after mixing is carried out, and therefore a new surface alloy layer is formed on the laser fusion part of the cutter. By means of the laser repairing and strengthening composite treating method, defects on the surface of the damage cutter can be rapidly repaired, the mechanical property like hardness is improved, continuous operation can be achieved, and the service life of the cutter is prolonged.

Description

Technical field: [0001] The invention relates to the technical field of mechanical manufacturing and material processing and processing applications; in particular, it relates to a composite processing method for laser repair and strengthening of damaged cutting tools of shearing equipment. Background technique: [0002] Laser melting (LaserRemelting) is also called laser glazing. It uses a high-energy laser beam to continuously scan the metal surface to rapidly melt the thin layer on the surface, and under the action of a very high temperature gradient, the 5 ~10 7 The speed of ℃ / s is rapidly cooled and solidified, so that a special microstructure is produced on the surface of the material. Laser melting requires high laser energy and fast cooling; surface cracks and defects can be welded through the melting process, surface composition segregation is reduced, and metastable or even amorphous phases such as highly supersaturated solid solutions are formed. The fused layer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C24/10

Inventor 任旭东徐士东戴文杰殷文元任乃飞谢善忠张晓荣尹小琴张西良王匀王存堂崔卫东谢方伟

Owner JIANGSU WANLI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com