Medium-strength fiber and processing equipment thereof

A processing equipment and strength technology, applied in the field of fiber manufacturing, can solve the problems of poor dimensional stability, low breaking strength, low tensile setting temperature, etc., and achieve the effect of stable internal structure, good dimensional stability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the processing of strong yarn in chip spinning 550dtex / 96f

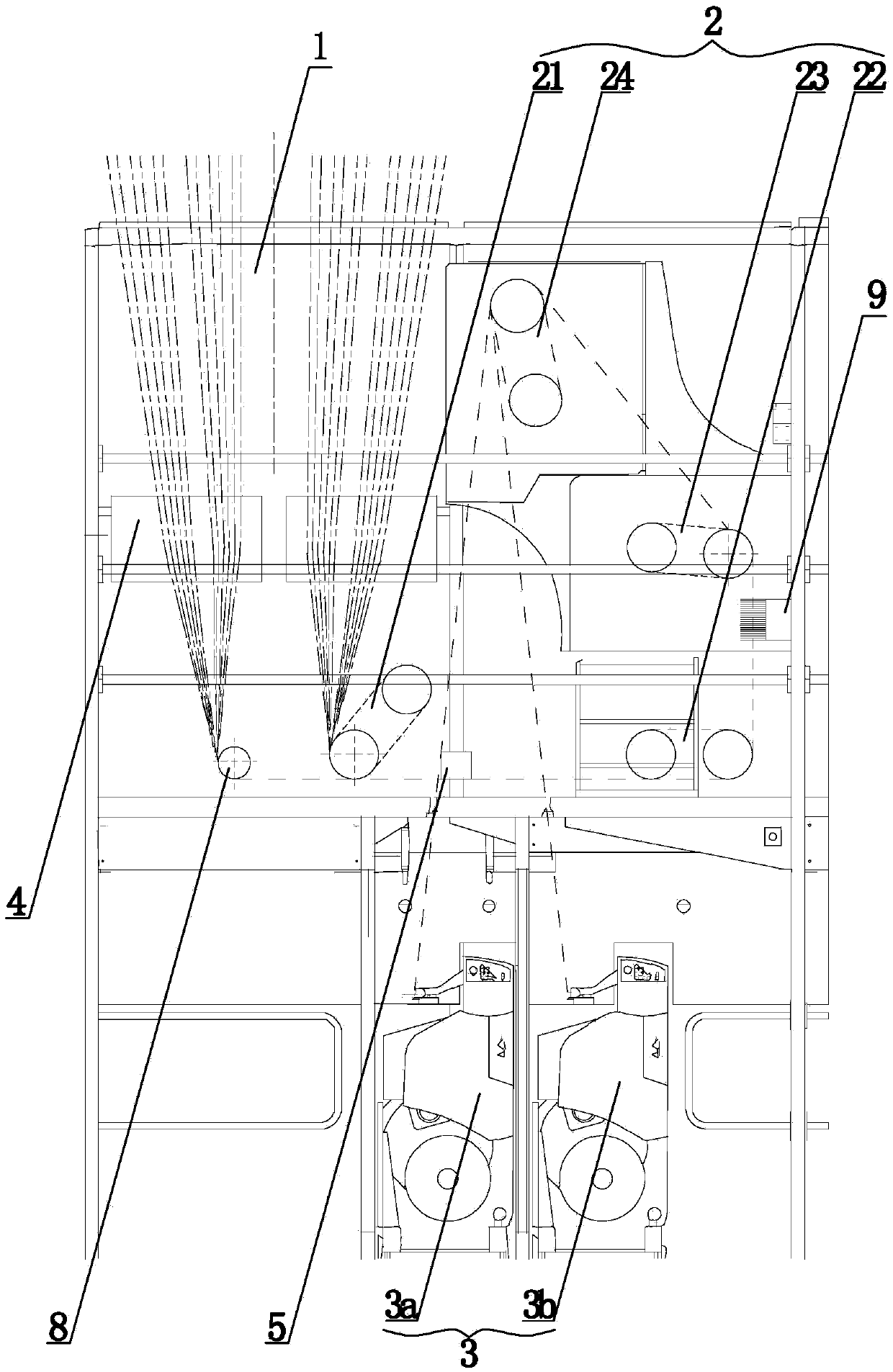

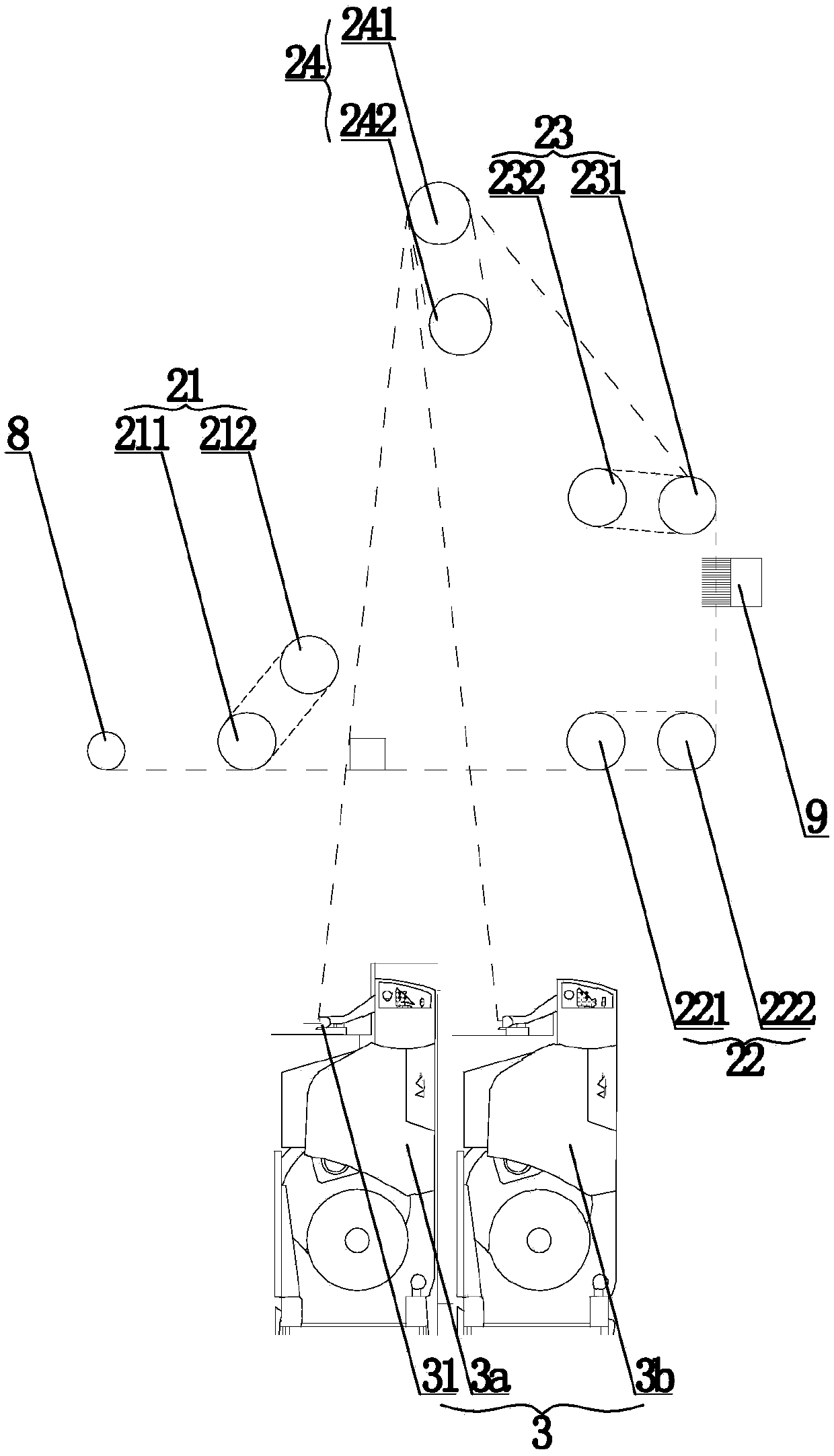

[0036] A kind of processing equipment of medium-strength wire in this embodiment, combined with figure 1 with figure 2 , consisting of a screw extruder, a spinning box, a side blower mechanism, a spinning tunnel 1, a stretching and setting roller 2 and a winding mechanism 3 installed in sequence, the screw extruder, a spinning box, and a spinning tunnel 1 are installed sequentially from top to bottom; the outlet of spinning tunnel 1 is provided with oil nozzle 4 for oiling; four pairs of stretching and setting rollers 2 are arranged, the first pair of rollers 21 are located under spinning tunnel 1, and the second pair of rollers 22 is located behind the first pair of rollers 21, a pre-internet device 5 is set between the second pair of rollers 22 and the first pair of rollers 21, the third pair of rollers 23 is located above the second pair of rollers 22, and the fourth pair of rollers 24 is lo...

Embodiment 2

[0044] Embodiment 2: Processing of melt direct spinning 840dtex / 192f medium strong yarn

[0045] The setting and working principle of this embodiment and embodiment 1 are the same, and the difference is that: this embodiment uses polyester melt as raw material, and the viscosity of this raw material is at 0.85-1.10dl / g; And the silk road between the 4th roller 222 and the 5th roller 231 is provided with a comb-type yarn separator 9, which is used to divide the silk sliver conveyed by the second pair of rollers 22 into two, so that the silk sliver can pass through the 3rd pair of rollers 23, Uniform shaping and stretching on the fourth pair of rollers 24, at the same time, two sets of winding mechanisms can be arranged on each corresponding group of processing equipment, that is, winding mechanism one 3a and winding mechanism two 3b, and the corresponding winding head 31 is also There are two sets, and the filaments after stretching and heat setting can be supplied to winding m...

Embodiment 3

[0049] Embodiment 3: processing of melt direct spinning 550dtex / 96f medium strong yarn

[0050] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: a godet roller 8 is arranged in front of the first roller 211, and a comb-type yarn separator 9 is arranged on the silk road between the fourth roller 222 and the fifth roller 231 , used to divide the filaments conveyed by the second pair of rollers 22 into two, so as to facilitate the uniform shaping and stretching of the filaments on the third pair of rollers 23 and the fourth pair of rollers 24. At the same time, each group of corresponding processing equipment Two sets of winding mechanisms can be provided, that is, winding mechanism one 3a and winding mechanism two 3b, and two corresponding winding heads 31 are also provided, and the filaments after stretching and heat setting can be supplied to winding mechanism one 3a respectively And winding mechanism 2 3b, not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com