Preparation method of highly-dispersed Ni catalyst used for producing synthesis gas through carbon dioxide reforming of methane

A carbon dioxide and catalyst technology, applied in the fields of natural gas chemical industry and catalyst manufacturing engineering, can solve the problems of complex preparation process and no stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of carrier SBA-15:

[0032] Weigh 12.00g triblock copolymer P123 (polyethylene glycol-polypropylene glycol-polyethylene glycol, (PEG)x -(PPG) y -(PEG) z , M n ≈5800, Sigma-Aldrich), which was dissolved in a mixed solution of 51 ml of commercially available concentrated hydrochloric acid with an HCl content of 36.0-38.0% and 366 ml of deionized water. Add 28.5ml tetraethyl orthosilicate dropwise to the above homogeneous solution, and then stir at 35°C for 20h. Seal the flask containing the above mixed solution and place it in an oven at 80°C for 24 hours to age to obtain a liquid-solid mixture. Finally, the above-mentioned liquid-solid mixture was suction-filtered to separate the solid, and the solid was repeatedly washed with deionized water until neutral, and then dried in an oven at 40°C for 48 hours to obtain a solid mesoporous silica powder containing a template. The above solid powder was placed in a muffle furnace, calcined at 500° C. for 6 hou...

Embodiment 2

[0048] (1) Preparation of carrier SBA-15:

[0049] Each step is with embodiment 1.

[0050] (2) Preparation of catalyst Ni / SBA15-P123 (1 / 500):

[0051] In addition to adding the amount of P123 is 0.0099g (n P123 / n Ni =1 / 500), other with embodiment 1. The resulting catalyst was labeled Ni / SBA15-P123 (1 / 500). The loading amount (mass percentage) of Ni is 4.76wt%.

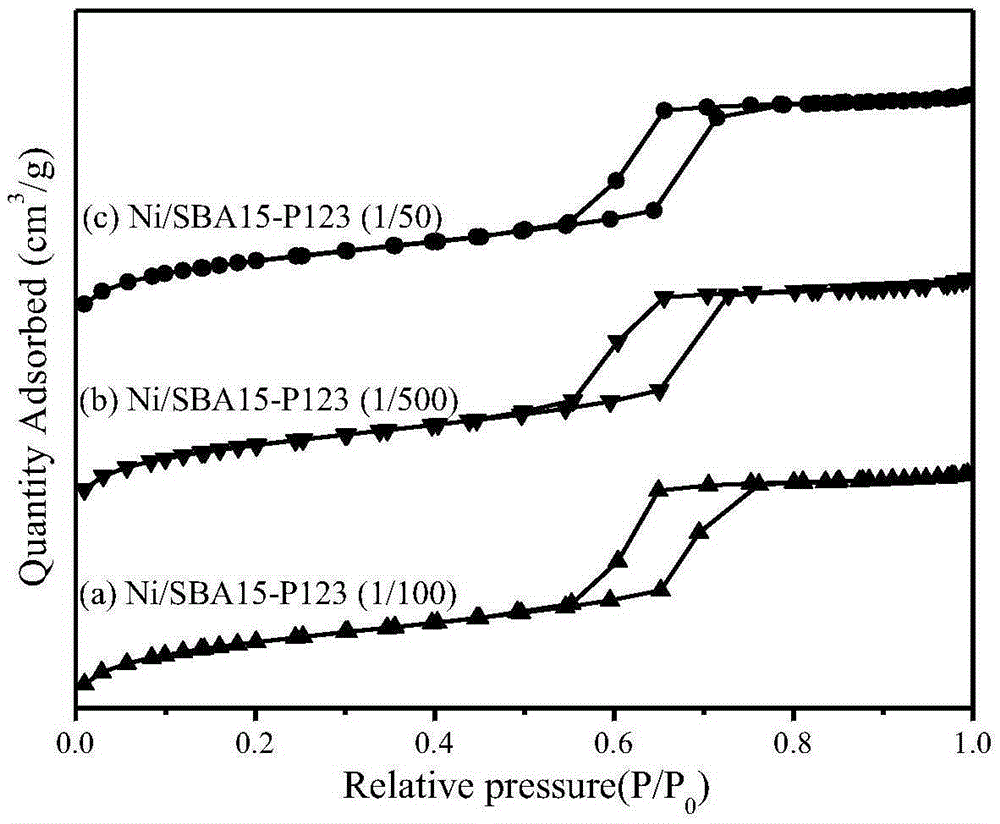

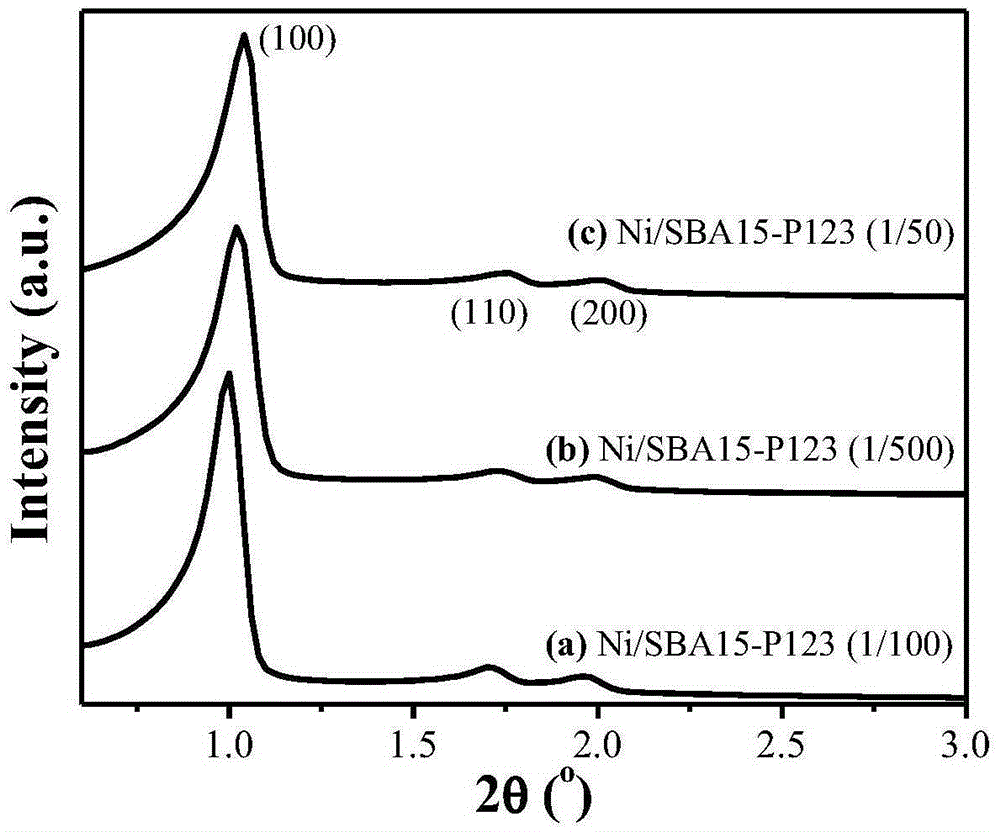

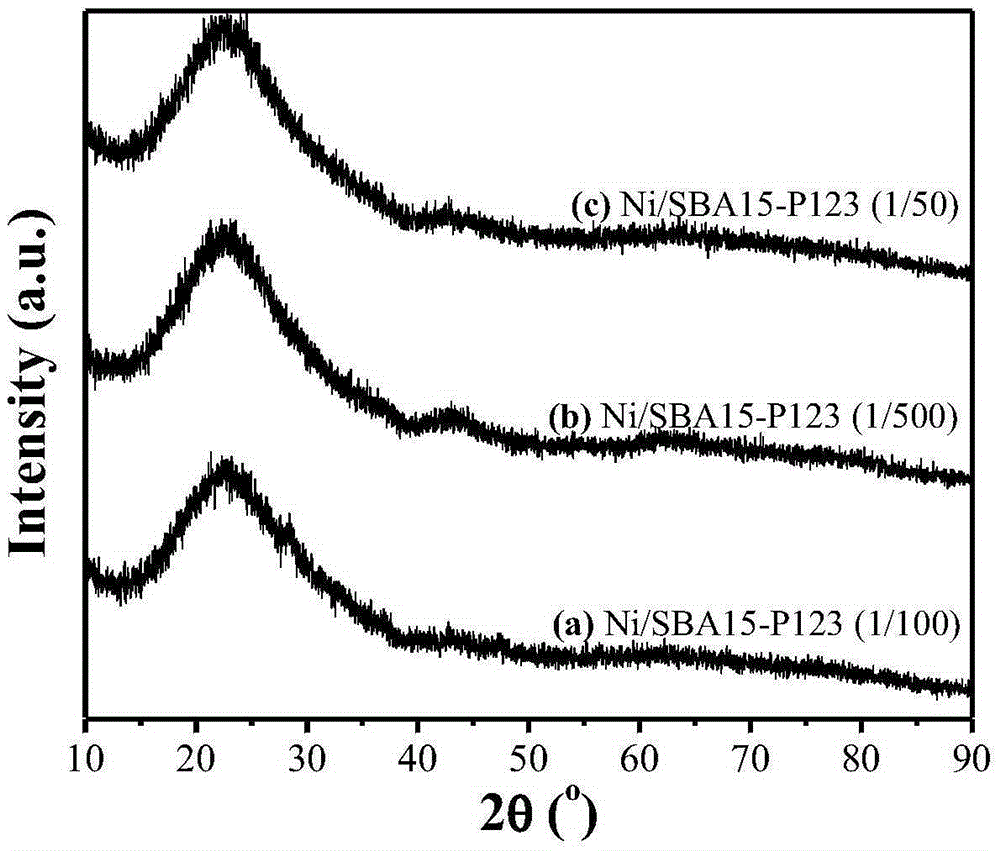

[0052] (3) Analysis and characterization of the catalyst

[0053] Cryogenic N 2 The structural characteristics of the fresh catalyst were characterized by adsorption-desorption and small-angle X-ray diffraction (XRD), and the results are listed in figure 1 (b) and figure 2 (b). The results show that the freshly prepared Ni / SBA15-P123(1 / 500) catalyst maintains the two-dimensional hexagonal ordered mesoporous structure of SBA-15. In addition, the catalyst was also characterized by wide-angle XRD, and the results are listed in image 3 (b), no diffraction peak attributed to the NiO crystal phase was detecte...

Embodiment 3

[0057] (1) Preparation of carrier SBA-15:

[0058] Each step is with embodiment 1.

[0059] (2) Preparation of catalyst Ni / SBA15-P123 (1 / 50):

[0060] In addition to adding the amount of P123 is 0.0988g (n P123 / n Ni =1 / 50), other with embodiment 1. The resulting catalyst was labeled Ni / SBA15-P123 (1 / 50). The loading amount (mass percentage) of Ni is 4.76wt%.

[0061] (3) Analysis and characterization of the catalyst

[0062] Cryogenic N 2 The texture properties of fresh catalysts were characterized by adsorption-desorption and small-angle X-ray diffraction (XRD), and the results are listed in figure 1 (c) and figure 2 (c). The results showed that the freshly prepared Ni / SBA15-P123(1 / 50) catalyst maintained the mesoporous structure of SBA-15. The characterization results of wide-angle XRD are listed in image 3 (c), the results show that no diffraction peaks attributed to the NiO crystal phase are detected, indicating that the Ni component on the calcined Ni / SBA15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com