Method for eliminating 3D printing wax type supporting material

A technology of 3D printing and supporting materials, applied in the field of 3D printing technology and post-processing, it can solve the problems of difficult to completely remove wax, adverse effects on appearance, structure and performance, and achieve the effect of low cost, low environmental requirements and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

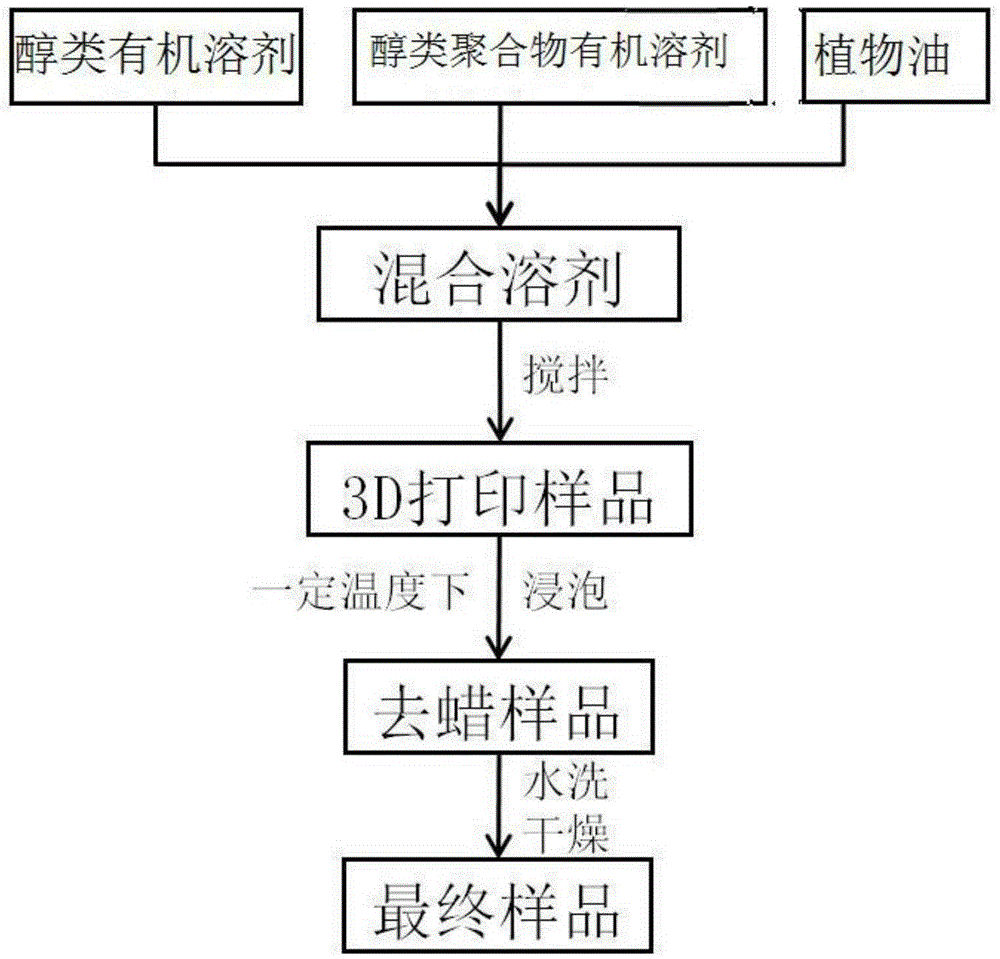

Method used

Image

Examples

Embodiment 1

[0020] The Projet5000 equipment of 3DSystem Company was used to make 3D printing samples. The molding material was yellow translucent photosensitive resin, and the supporting material was 100% wax-type material. Propanol, polypropylene glycol and soybean oil are uniformly stirred at a volume ratio of 1:1:1 to prepare an organic mixed solvent. At 65°C, the 3D printed sample was soaked in an organic mixed solvent. After the wax-type support material was dissolved, the 3D printed sample was taken out for repeated washing, and the final 3D printed sample was obtained after drying.

[0021] The results show that the appearance of the 3D printed sample remains yellow and translucent, the surface is clean without white wax layer, and no residual oil wax gel is found in its microstructure. While the mixed solvent dissolves the wax-type support material, it does not affect the appearance, surface quality, size and fine structure of the 3D printing sample.

Embodiment 2

[0023] The Projet5000 equipment of 3DSystem Company was used to make 3D printing samples. The molding material was yellow translucent photosensitive resin, and the supporting material was 100% wax-type material. Mix isopropanol, polyethylene glycol and soybean oil uniformly at a volume ratio of 1:1:1 to prepare an organic mixed solvent. At 65°C, the 3D printed sample was soaked in an organic mixed solvent. After the wax-type support material was dissolved, the 3D printed sample was taken out for repeated washing, and the final 3D printed sample was obtained after drying.

[0024] The results show that the appearance of the 3D printed sample remains yellow and translucent, the surface is clean without white wax layer, and no residual oil wax gel is found in its microstructure. While the mixed solvent dissolves the wax-type support material, it does not affect the appearance, surface quality, size and fine structure of the 3D printing sample.

Embodiment 3

[0026] The Projet5000 equipment of 3DSystem Company was used to make 3D printing samples. The molding material was yellow translucent photosensitive resin, and the supporting material was 100% wax-type material. Mix isopropanol, polyethylene glycol and peanut oil uniformly at a volume ratio of 1:1:2 to prepare an organic mixed solvent. At 70°C, the 3D printed sample was soaked in an organic mixed solvent. After the wax-type support material was dissolved, the 3D printed sample was taken out and washed repeatedly, and the final 3D printed sample was obtained after drying.

[0027] The results show that the appearance of the 3D printed sample remains yellow and translucent, the surface is clean without white wax layer, and no residual oil wax gel is found in its microstructure. While the mixed solvent dissolves the wax-type support material, it does not affect the appearance, surface quality, size and fine structure of the 3D printing sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com