Glass, light guide plate, backlight unit, liquid crystal panel, liquid crystal display terminal and preparation method of glass

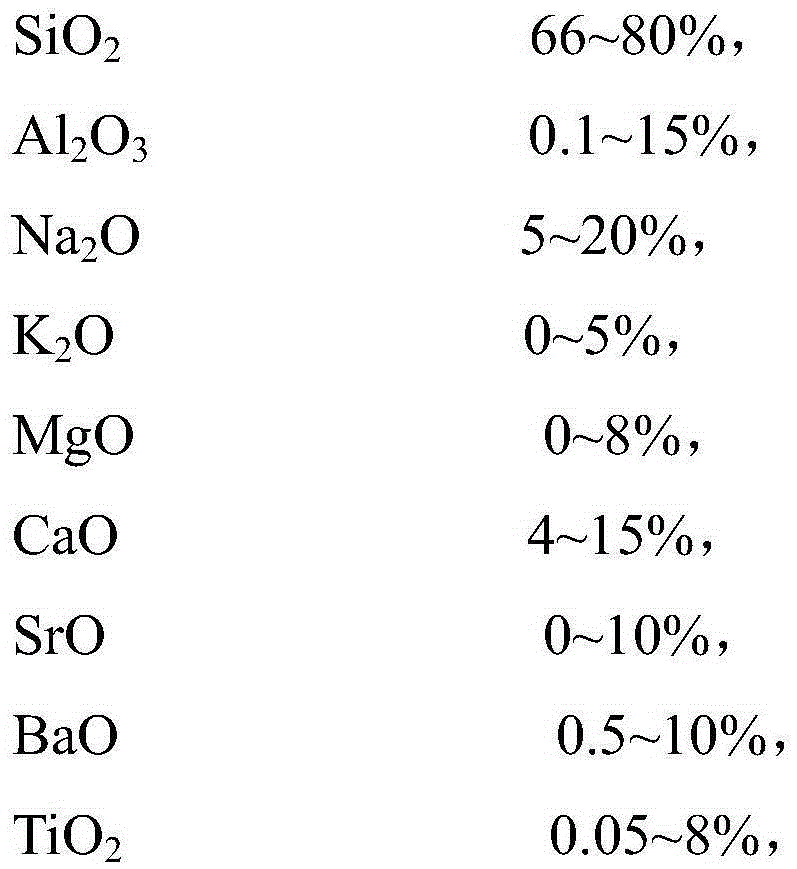

A technology of backlight module and liquid crystal panel, applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problem of large thermal expansion coefficient, low strain point, shape and size will be affected by environmental humidity changes and deformation, etc. problem, to achieve the effect of low thermal expansion coefficient and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

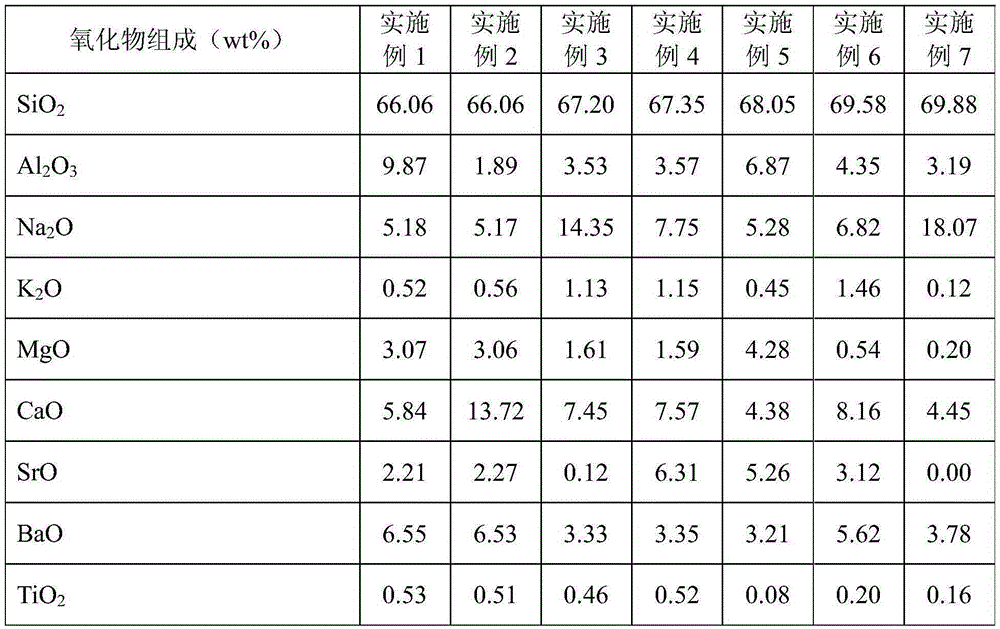

Embodiment 1

[0042] Convert and weigh the corresponding raw materials according to the components and their mass percentages in Table 1; mix the weighed raw materials evenly and pour them into platinum crucibles, and melt them in a silicon-molybdenum rod high-temperature melting furnace to keep the glass The liquid is kept in the range of 1400°C to 1480°C and kept warm for 3 to 10 hours. At the same time, a platinum rod is used to stir the air bubbles and homogenize the glass liquid; then the melted glass liquid is cooled to the temperature range required for molding, and the After annealing, glass of the desired thickness is produced. The total iron content of harmful components in glass is expressed as Fe 2 o 3 The mass percentage content of the meter is not more than 0.01%. The physical properties of the obtained glass were tested, and the test results are shown in Table 1.

Embodiment 2

[0044] Repeat the method of Example 1 according to the mass percentage of each component in Table 1 below. The test results of the obtained glass are shown in Table 1.

Embodiment 3

[0046] Repeat the method of Example 1 according to the mass percentage of each component in Table 1 below. The test results of the obtained glass are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com