A kind of cement for non-pressure steamed c80 concrete pile

A technology for concrete piles and free of pressure steaming is applied in the field of cement for concrete piles, which can solve the problems affecting the durability of concrete, shorten the construction period, delay and the like, and achieve the effects of saving energy consumption, short production period and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

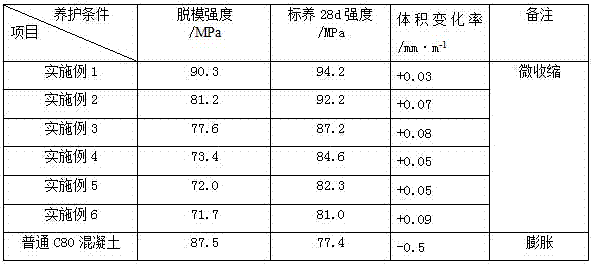

Examples

Embodiment 1

[0028] A pressure-free steamed C80 cement for concrete piles comprises the following raw materials in mass percentage: 88.85% of Portland cement clinker, 8% of mineral powder, and 3% of silica fume.

[0029] After mixing the three materials evenly, add 0.15% sodium gluconate, and the performance indicators of the prepared cement for steam-free pipe pile concrete are as follows: the specific surface area is 410m 2 / kg, 80μm square hole sieve remaining 2%; initial setting time 18min, final setting time 40min; 3d flexural strength 6.7MPa, compressive strength 46.6MPa, 28d flexural strength 8.0MPa, compressive strength 60.5MPa.

[0030] In this embodiment, the mineral composition of Portland cement clinker is as follows: tricalcium silicate 55.3%, dicalcium silicate 18.3%, tricalcium aluminate 8.5%, tetracalcium aluminoferrite 14%, free calcium oxide 1%, calcined Lost 2.9%.

[0031] In the present embodiment, the specific surface area of slag powder is 450m 2 / kg, fluidity rat...

Embodiment 2

[0034] A pressure-free steamed C80 cement for concrete piles comprises the following raw materials in mass percentage: 89.9% of Portland cement clinker, 5% of mineral powder, and 5% of silica fume.

[0035] After mixing the three materials evenly, adding 0.1% sodium gluconate, the performance indicators of the prepared non-pressure steamed C80 concrete pile cement are as follows: specific surface area 430m 2 / kg, 80μm square hole sieve residue 1.7%; initial setting time 17min, final setting time 41min; 3d flexural strength 6.5MPa, compressive strength 45.5MPa, 28d flexural strength 8.2MPa, compressive strength 62MPa.

[0036] In this embodiment, the mineral composition of Portland cement clinker is as follows: tricalcium silicate 58%, dicalcium silicate 18%, tricalcium aluminate 7.9%, tetracalcium aluminoferrite 12%, free calcium oxide 2.9%, calcined Lost 1.2%.

[0037] In the present embodiment, the specific surface area of slag powder is 450m 2 / kg, fluidity ratio 90%, 7...

Embodiment 3

[0040] A pressure-free steamed C80 cement for concrete piles comprises the following raw materials in mass percentage: 66.8% of Portland cement clinker, 28% of mineral powder, and 5.0% of silica fume.

[0041] After mixing the three materials evenly, adding 0.2% sodium gluconate, the performance indicators of the prepared non-pressure steamed C80 concrete pile cement are as follows: the specific surface area is 450 m 2 / kg, 1% remaining on 80μm square hole sieve; initial setting time 21min, final setting time 45min; 3d flexural strength 4.3MPa, compressive strength 25.6MPa, 28d flexural strength 6.2MPa, compressive strength 52.3MPa.

[0042] In this example, the mineral composition of Portland cement clinker is as follows: tricalcium silicate 58%, dicalcium silicate 18%, tricalcium aluminate 8.2%, tetracalcium aluminoferrite 12%, free calcium oxide 0.9%, calcined Lost 2.9%.

[0043] In the present embodiment, the mineral powder specific surface area is 425 m 2 / kg, fluidity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com