Waterborne epoxy zinc-rich coating rich in microcapsule structure modified zinc powder and its preparation

A water-based epoxy zinc-rich, microcapsule structure technology, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problem of poor corrosion resistance and water resistance of film-forming systems, insufficient dispersion of zinc powder, and volatility. The problem of high organic content can improve the water resistance and impact resistance of the paint film, good low temperature curing performance, and improve the dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 A kind of polysilane modified zinc powder

[0052] Add 0.45 g of commercially available Z-6172 Silane polysilane from Dow Corning Company to 450 g of isopropanol to prepare a polysilane treatment agent. Spray the prepared polysilane treatment agent mist onto the zinc powder surface within 10 minutes in the rotary furnace, continue to stir for 10 minutes, make it fully mixed, and remove the isopropanol solvent under vacuum to obtain 59.5g polysilane Modified zinc powder.

Embodiment 2

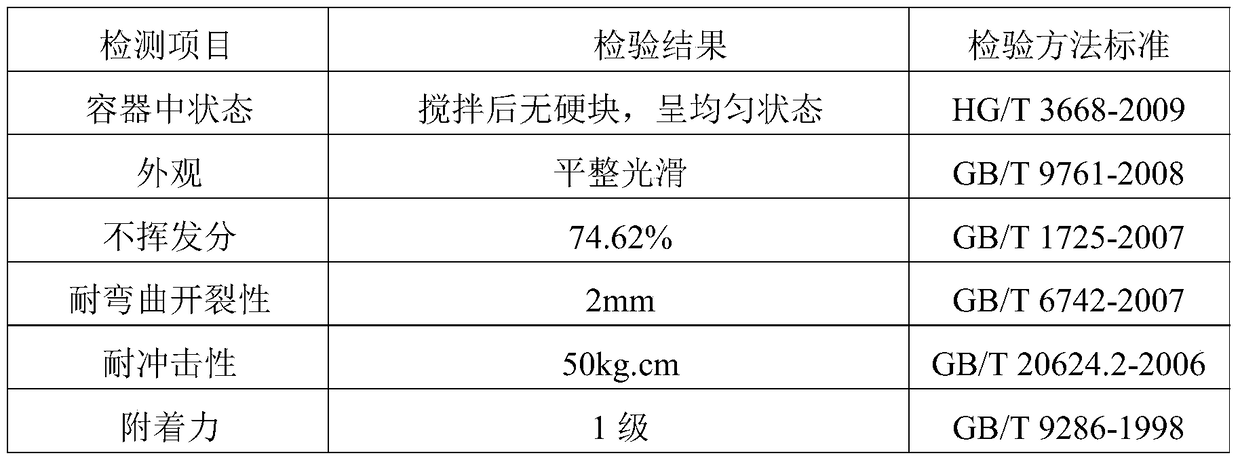

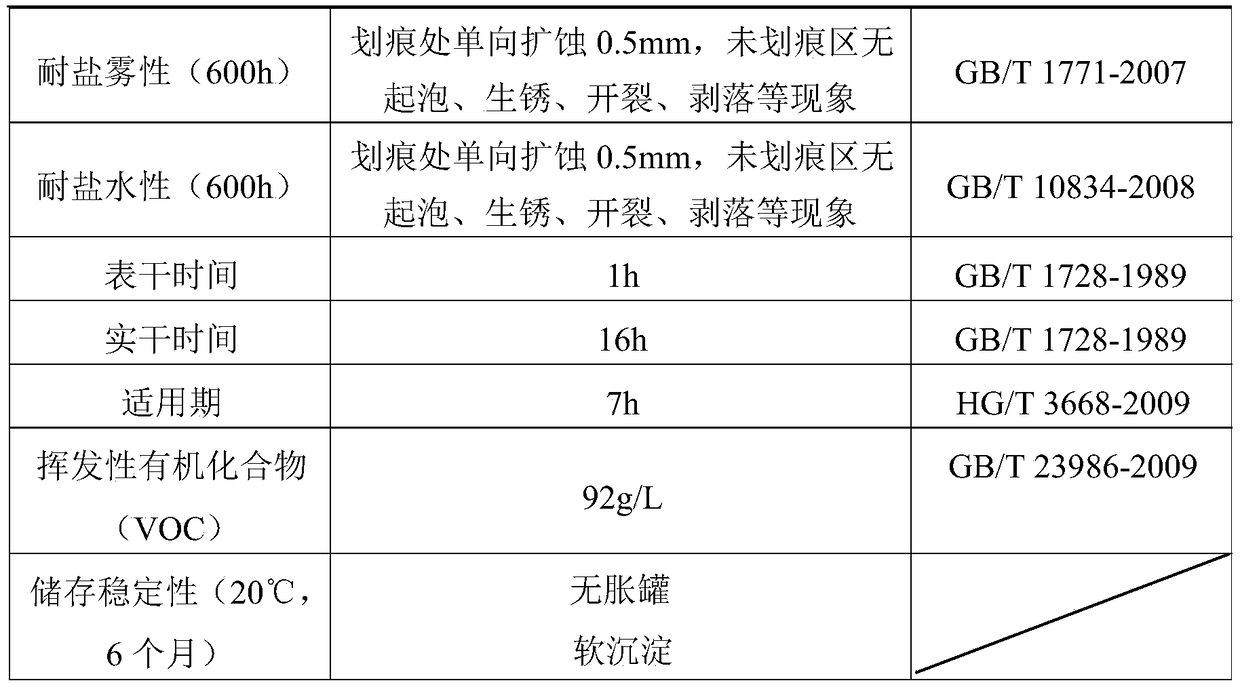

[0053] Embodiment 2 is rich in the waterborne epoxy zinc-rich paint of microcapsule structure modified zinc powder

[0054] Add 0.45 g of polysilane to 450 g of isopropanol to make polysilane treatment agent. Spray the prepared polysilane treatment agent alcohol aqueous solution mist on the surface of zinc powder within 10 minutes in a rotary furnace, continue stirring for 10 minutes, make it fully mixed, and remove the isopropanol solvent under vacuum to obtain 59.5g Polysilane modified zinc powder.

[0055] Premix 20.24g of epoxy emulsion, 0.75g of bentonite, 0.82g of fumed silica, 2.88g of propylene glycol phenyl ether, and 5.23g of deionized water, and add 59.50g of the above-mentioned polysilane-modified zinc powder to the above-mentioned mixture under stirring In the process, disperse the mixture at a high speed for more than 30 minutes at a speed of not less than 1500 rpm until the fineness is less than 40 microns.

[0056] Mix 5.08 g of epoxy resin amine adduct 1 and...

Embodiment 3

[0058] Embodiment 3 is rich in the waterborne epoxy zinc-rich paint of microcapsule structure modified zinc powder

[0059] Add 0.42 g of polysilane to 420 gram of isopropanol to make polysilane treatment agent. Spray the prepared polysilane treatment agent alcohol aqueous solution mist on the zinc powder surface within 10 minutes in the rotary furnace, continue to stir for 10 minutes, make it fully mixed, and remove the isopropanol solvent under vacuum to obtain 56.2g Polysilane modified zinc powder.

[0060] Premix 22.4g of epoxy emulsion, 0.7g of bentonite, 0.8g of fumed silica, 2.94g of propylene glycol phenyl ether, and 5.07g of deionized water, and add 56.2g of the above-mentioned polysilane-modified zinc powder to the above mixture under stirring In the process, disperse the mixture at a high speed for more than 30 minutes at a speed of not less than 1500 rpm until the fineness is less than 40 microns.

[0061] Mix 5.54 g of epoxy resin amine adduct 1 and 2.3 g of epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com