Waterproof wired component and its production equipment and method

A kind of production equipment and waterproof technology, applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of NTC temperature sensor inconsistency in appearance, inconsistency in reflection speed, low production efficiency, etc., to achieve mass production and location The effect of good consistency and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0029] The first embodiment is a waterproof wired component, which includes two leads and a chip welded between the two leads, and the leads and the chip are packaged and packaged by the same plastic part.

[0030] Among them, the plastic parts are made of PVC, XLPVC, XLPE, PE, PU, TPE, PP, PO, silica gel, rubber and or polytetrafluoroethylene. The chip is an LED light-emitting tube chip, a photoresistor or a thermistor. In this embodiment, the chip is a thermistor. Thermistors are single-ended glass-sealed thermistors, bead-shaped glass-sealed thermistors, diode-type thermistors, bare chip-type thermistors or chip-type thermistors. The lead wire is a metal lead wire formed by stretching, and the diameter of the metal lead wire is not more than 5 cm. The surface of the plastic part is electroplated with a metal layer or covered with a metal sleeve, or pasted with a metal sticker.

no. 2 example

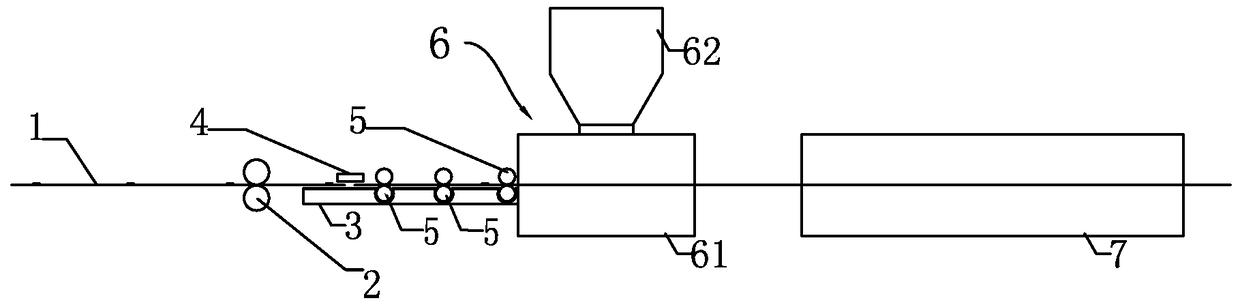

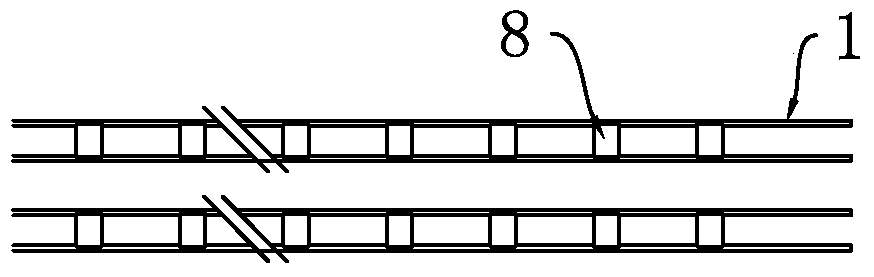

[0031] Second embodiment, such as figure 1 with figure 2 As shown, a production equipment for manufacturing waterproof wire components includes a first guide wheel 2, a punching die 4 located downstream of the first guide wheel 2 for punching the lead wire 1, and a punching die 4 located downstream of the punching die 4. In the guide groove 3 for conveying the punched lead wire 1, the second guide wheel 5 that guides the punched lead wire 1 in the guide groove 3, the injection molding device 6 that is positioned at the downstream of the guide groove 3 for injection molding the punched lead wire 1 and is located at the downstream of the injection device 6 for The water tank 7 where the lead wire 1 is cooled after injection molding; several NTC resistors 8 are welded at intervals between two parallel lead wires 1 to form a group of copper wires, and enter the punching die 4 through the first guide wheel 2, and the lead wires of the die 4 are punched out 1 punching, the punched...

no. 3 example

[0033] The third embodiment, a kind of production method of manufacturing waterproof strip line component, comprises:

[0034] Step 1, making lead groups, each lead group consists of two parallel lead wires and chips welded between the two parallel lead wires at intervals as required;

[0035] Step 2, debug the output speed of the lead wire and plastic;

[0036] Step 3, making unit modules, punching the leads of each lead group at the chip welding place to form several unit modules; the guide wheels and guide grooves send the punched leads to the injection molding device;

[0037] Step 4, the lead wire after injection is cooled in the water tank, and the wire is wound;

[0038] Step 5, cut off the plastic at the front of the chip at intervals, strip the leads and punch terminals and sockets.

[0039] The following takes the fabrication of a temperature sensor as an example for illustration. Specifically, the lead wire may be a copper wire, and the chip may be a thermistor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com