Starting hybrid power supply for diesel engine

A composite power supply, diesel engine technology, applied in multiple hybrid/electric double layer capacitors, circuits, current collectors, etc., can solve the problems of high production cost, impossible diesel engine start-up power supply for capacitors, no research on super capacitors, etc. The discharge rate, the effect of alleviating the peak discharge process, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

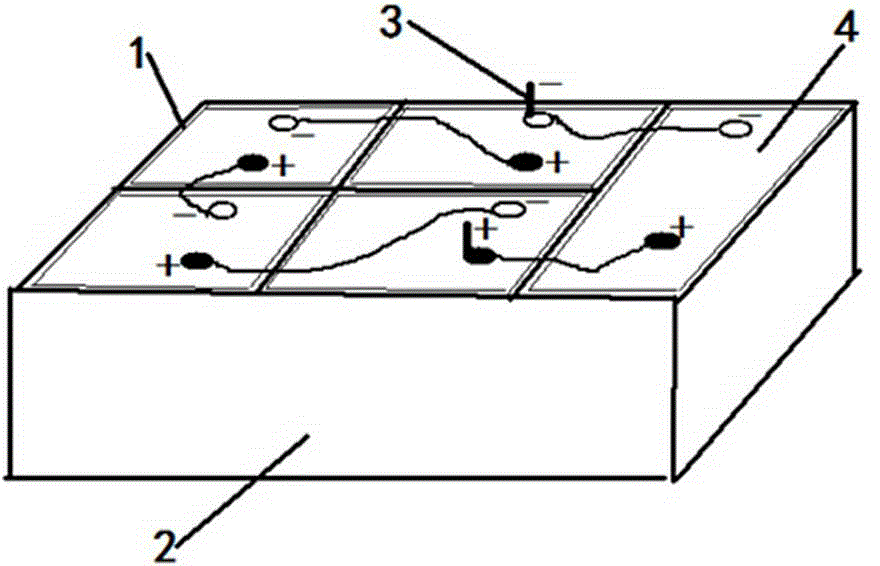

Image

Examples

Embodiment 1

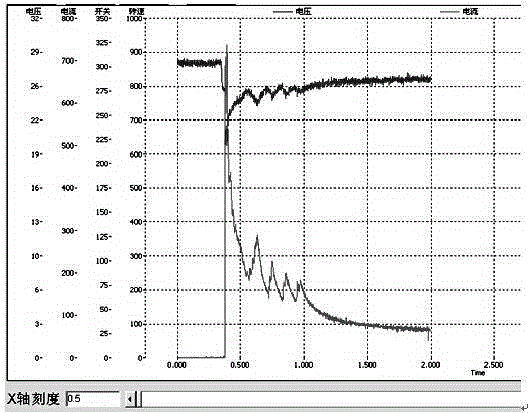

[0035] Embodiment 1: Measuring the current and voltage at the moment of starting a diesel engine with a separate battery

[0036] This part of the experiment was completed in the bench test center of Xiangyang Dongfeng Automobile Electric Co., Ltd. The lead-acid battery used is a brand-new Camel 80Ah lead-acid battery with a rated voltage of 12V. The final voltage of the two batteries connected in series is 25.1V. , The measured internal resistance is 17.4mΩ. Connect the assembled battery to the starter motor of the stand. The power of the starter motor is 6-8kw, the rated voltage is 24V, the model of the diesel engine is Cummins ISDe-270-30, and the rated power of the diesel engine is 198kw. This diesel engine is equipped with a generator with a maximum output voltage of 28V and a maximum output current of 90A. After the power supply is connected, the diesel engine is started to ignite. Due to the floating charge, the final voltage of the lead-acid battery reaches 28V. The...

Embodiment 2

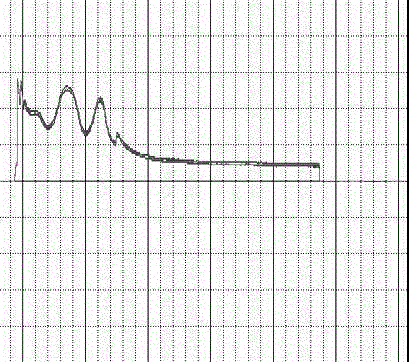

[0039] Embodiment 2: The discharge response time of the storage battery part and the capacitor part

[0040] Through theoretical knowledge, lead-acid batteries are chemical batteries, and there is a time for chemical reactions to occur during the discharge process, while the charging and discharging process of inorganic supercapacitors is a physical process, and it takes a certain amount of time for chemical reactions to occur, so the discharge process of the capacitor Will it be faster than the battery, resulting in inconsistent peak current discharge time, and ultimately fail to achieve the desired effect. In order to complete the above experiment, we used two more sophisticated fluke clamp meters and a Japanese oscilloscope for the experiment. The model of diesel engine used in this experiment is YC6105QC, the rated power is 105kw, and the starter power is 6.5kw. The voltage of the diesel engine starting compound power supply used is 25.1V, and the internal resistance is ...

Embodiment 3

[0045] Example 3: Influence of Internal Resistance on the Peak Current Sharing Ratio of Diesel Engine Starting Composite Power Supply

[0046] The diesel engine of Example 2 is also used, and capacitors with different internal resistances are used to connect batteries in parallel. The specific measurement and detection are the same as in Example 2. In order to ensure the accuracy of the results, two measurements were performed for each combination of capacitor pack and storage battery pack, and the results are shown in Table 1:

[0047] Table 1 The influence of the internal resistance of the battery and the internal resistance of the capacitor on the proportion of the peak current that the capacitor bears.

[0048]

[0049] It can be seen from Table 1 that the peak current that the capacitor can bear mainly depends on the internal resistance of the capacitor. The smaller the internal resistance of the capacitor, the larger the proportion it bears according to Ohm's law. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com