N regulated Pt/UiO-67 composite material with high stability as well as preparation method and application thereof

A composite material and high stability technology, applied in the direction of organic compound/hydride/coordination complex catalyst, separation method, chemical instrument and method, etc., can solve the problem of high price, easy agglomeration of noble metal nanoparticles, inhibition of development, etc. problem, to achieve uniform distribution, good CO catalytic oxidation effect, good thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

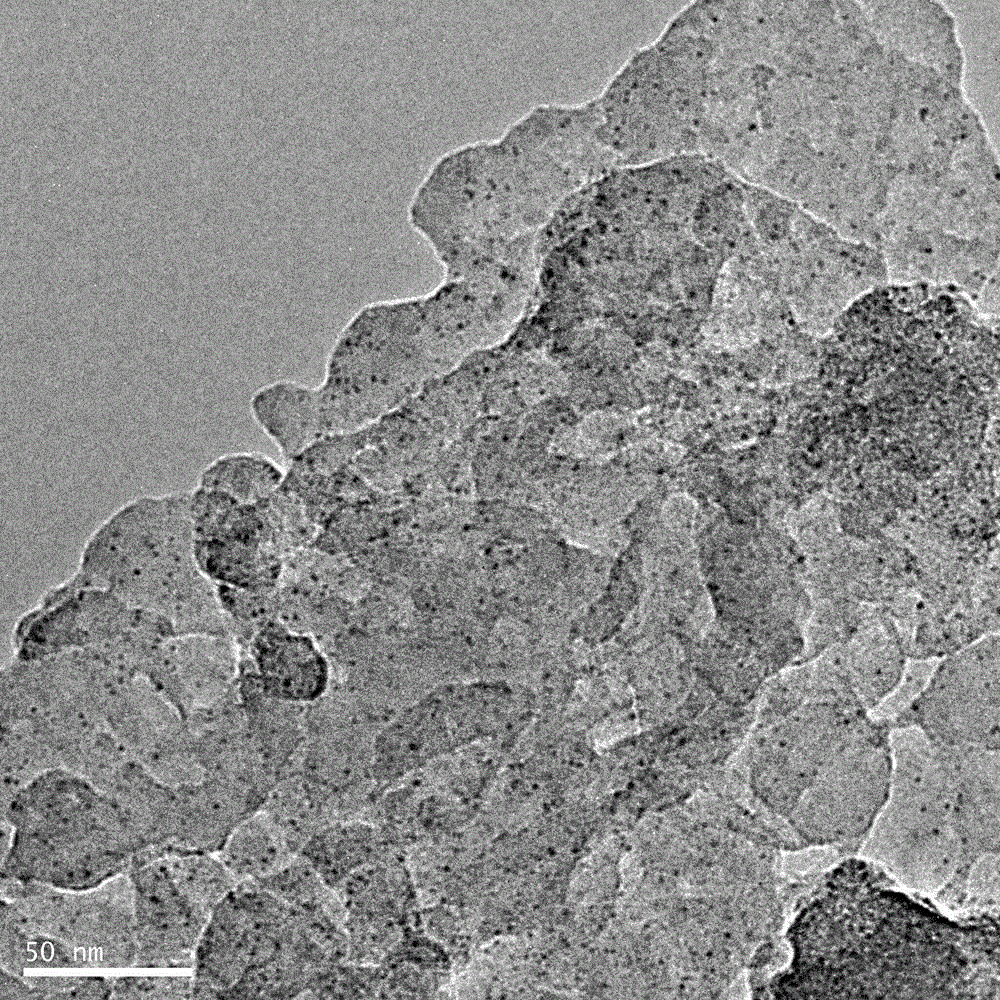

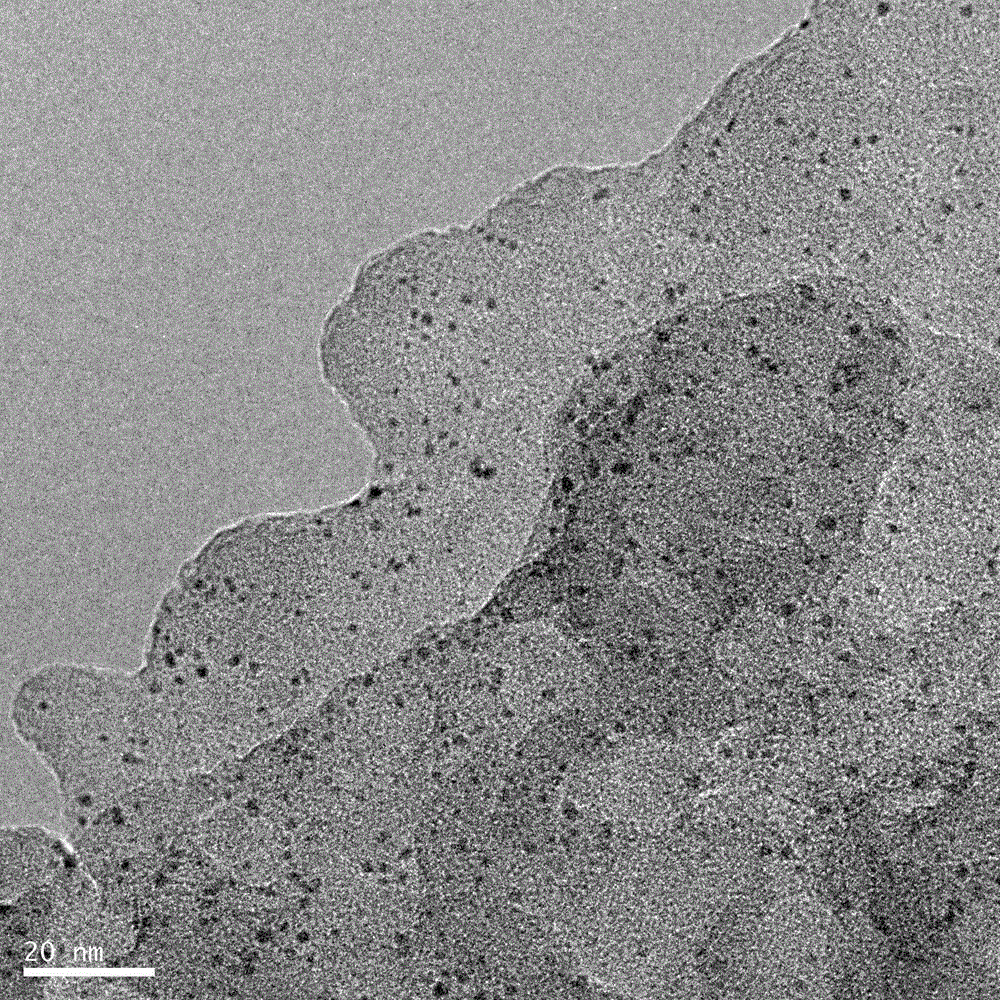

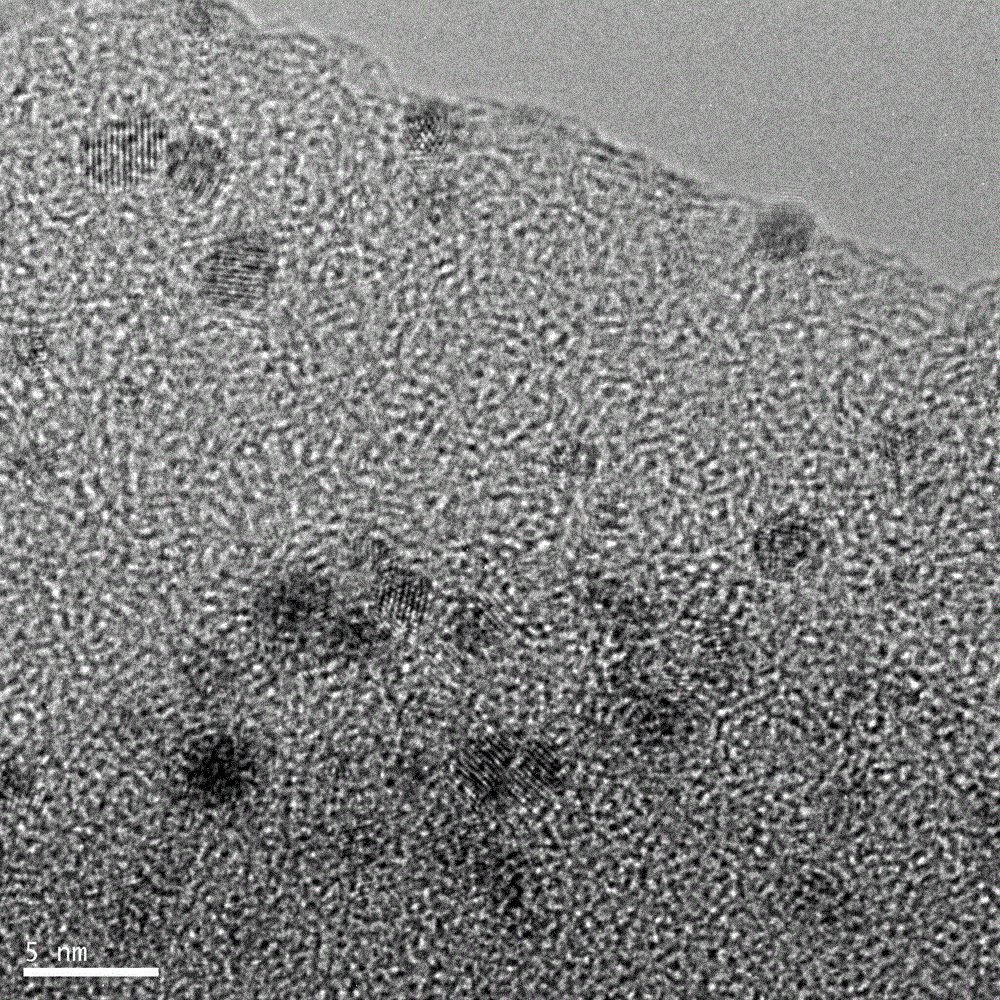

Image

Examples

Embodiment 11

[0035] Embodiment 11.0% N regulates the preparation of Pt / UiO-67 composite material

[0036] Mix 23.3mg of zirconium chloride and 24.3mg of 6-(4-hydroxyphenyl)nicotinic acid into a 25ml polytetrafluoroethylene liner, add 3ml of DMF, heat at 120°C for 24 hours, filter, wash, and dry to obtain a new MOFsN-UiO-67.

[0037] Weigh 0.1g of N-UiO-67 and ultrasonically dissolve it in 8ml of DMF solution, meanwhile, weigh 0.0022g of K 2 PtCl 4 The DMF solution was added dropwise to the above solution, at room temperature, ultrasonicated for 1 hour, then transferred to a 25ml round bottom flask and stirred for 8 hours, so that the Pt ions were fully adsorbed and evenly dispersed on the surface of the carrier. Freshly prepared NaBH 4 The solution was slowly added dropwise to the above mixed solution, and the Pt 2+ Restored to Pt atoms, in this process, the color of the solution can be seen to change from yellow to black, aging for half an hour, so that Pt 2+ After complete reduction...

Embodiment 23

[0041] Example 23.0% N regulates the preparation of Pt / UiO-67 composite material

[0042] Mix 23.3mg of zirconium chloride and 24.3mg of 6-(4-hydroxyphenyl)nicotinic acid into a 25ml polytetrafluoroethylene liner, add 3ml of DMF, heat at 120°C for 24 hours, filter, wash, and dry to obtain a new MOFsN-UiO-67.

[0043] Weigh 0.1g of N-UiO-67 and ultrasonically dissolve it in 8ml of DMF solution, meanwhile, weigh 0.0067g of K 2 PtCl 4 The DMF solution was added dropwise to the above solution, at room temperature, ultrasonicated for 1 hour, then transferred to a 25ml round bottom flask and stirred for 8 hours, so that the Pt ions were fully adsorbed and evenly dispersed on the surface of the carrier. Freshly prepared NaBH 4 The solution is slowly added dropwise to the above mixed solution to reduce Pt2+ to Pt atoms. In this process, the color of the solution can be seen to change from yellow to black. After aging for half an hour, the Pt 2+ After complete reduction, filter in ...

Embodiment 35

[0045] Example 35.0% N regulates the preparation of Pt / UiO-67 composite

[0046] Mix 23.3mg of zirconium chloride and 24.3mg of 6-(4-hydroxyphenyl)nicotinic acid into a 25ml polytetrafluoroethylene liner, add 3ml of DMF, heat at 120°C for 24 hours, filter, wash, and dry to obtain a new MOFsN-UiO-67.

[0047] Weigh 0.1g of N-UiO-67 and ultrasonically dissolve it in 8ml of DMF solution, meanwhile, measure 0.01144g of K 2 PtCl 4 The DMF solution was added dropwise to the above solution, at room temperature, ultrasonicated for 1 hour, then transferred to a 25ml round bottom flask and stirred for 8 hours, so that the Pt ions were fully adsorbed and evenly dispersed on the surface of the carrier. Freshly prepared NaBH 4 The solution is slowly added dropwise to the above mixed solution to reduce Pt2+ to Pt atoms. In this process, the color of the solution can be seen to change from yellow to black. After aging for half an hour, the Pt 2+ After complete reduction, filter in a sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com