Method for preparing phospholipids type DHA through catalysis of biological enzyme

A phospholipid-type, biological enzyme technology, applied in the direction of fermentation, etc., can solve the problems of low conversion rate of transesterification reaction, complex components of soybean phospholipids, unfavorable industrial production, etc., to avoid separation and purification operations, improve reaction efficiency and conversion rate, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

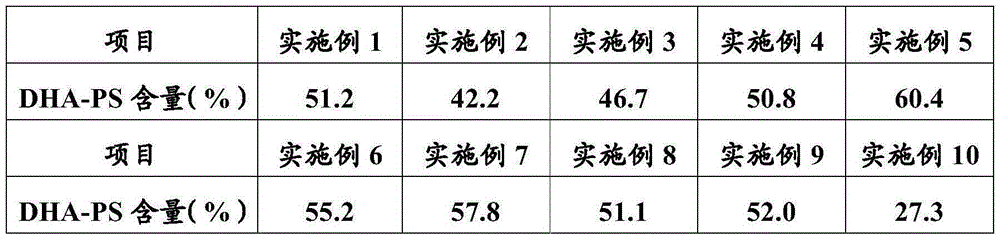

Embodiment 1

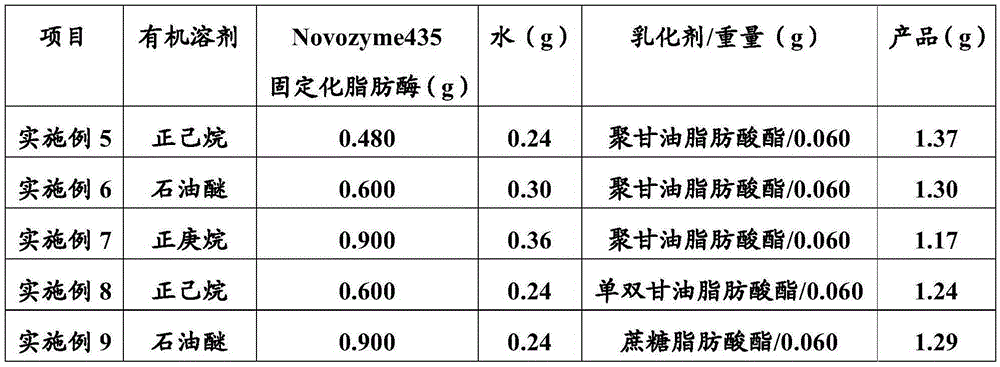

[0056] (1) Weigh 5.0g of algal oil DHA glyceride and dissolve it in 25mL of n-hexane to obtain the n-hexane solution of algal oil DHA ester; add 0.31g of Novozyme435 immobilized lipase and 0.30g of water, then add 0.025g of polyglycerol fatty acid ester, adjust the pH value of the mixture to be 6.7; 2 Place it on a constant temperature water bath and a magnetic stirring device under the protection of the hood, heat it to about 50°C in advance, and stir at a speed of 125r / min for 15-30min while heating. Slowly add phosphatidylserine (purity: 25%) n-hexane solution (1.01g phosphatidylserine is dissolved in 7mL n-hexane) dropwise under stirring, N 2 Under protection, the reaction was stirred at a constant speed for 18 hours under the condition of a water bath at 50°C.

[0057] (2) After the reaction, stand and filter to recover the catalyst biological enzyme; add 30mL of water to the organic phase to wash, then distill under reduced pressure in a water bath at 60°C to recover th...

Embodiment 2

[0059] (1) Weigh 6.0g of algal oil DHA glyceride and dissolve it in 42mL of n-hexane to obtain the n-hexane solution of algal oil DHA ester; add 0.72g of phospholipase A1 and 0.06g of water, and then add 0.06g of polyoxyethylene Sorbitan monooleate, adjust the pH value of the mixture to be 7.2; the above mixed solution in an inert gas N 2 Place it on a constant-temperature water bath and a magnetic stirring device under the protection of the hood, heat to 50°C in advance, and stir at a speed of 130r / min for 15-30min while heating. While stirring, a n-hexane solution (0.97 g of phosphatidylserine dissolved in 5 mL of n-hexane) dissolved in phosphatidylserine (purity: 50%) was slowly added dropwise. N 2 Under protection, the reaction was stirred at a constant speed in a water bath at 60°C for 27 hours.

[0060] (2) After the reaction was completed, the catalyst bio-enzyme was recovered by static filtration; the organic phase was washed with 30 mL of water, and then distilled u...

Embodiment 3

[0062] (1) Weigh 7.0g of algal oil DHA glyceride and dissolve it in 56mL of n-hexane to obtain the n-hexane solution of algal oil DHA ester; add 1.05g of phospholipase A2 and 0.28g of water, then add 0.06g of sucrose fatty acid ester, adjust the pH value of the mixture to 7.5; the above mixed solution in an inert gas N 2 Place it on a constant temperature water bath and a magnetic stirring device under the protection of the hood, heat to 50°C in advance, and stir at a speed of 150r / min for 15-30min while heating. Slowly add phosphatidylserine (purity: 50%) n-hexane solution (1.07g phosphatidylserine is dissolved in 7mL n-hexane) dropwise under stirring; N 2 Under protection, the reaction was stirred at a constant speed in a water bath at 60°C for 26 hours.

[0063] (2) After the reaction was completed, the catalyst bio-enzyme was recovered by static filtration; the organic phase was washed with 30 mL of water, and then distilled under reduced pressure in a water bath at 60° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com