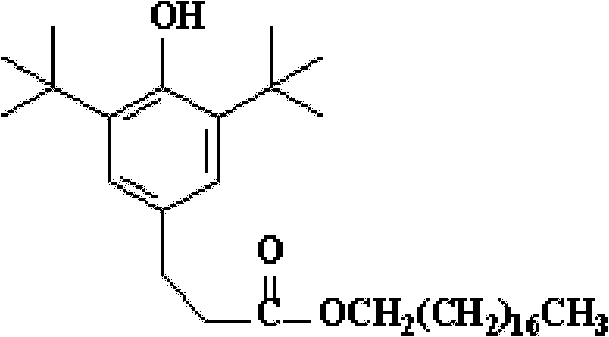

Synthesis method of antioxidant 1076 using solid base catalyst

A solid base catalyst, antioxidant technology, applied in chemical recovery, organic chemistry, ester group and hydroxyl reaction preparation and other directions, can solve the problems of cumbersome post-processing operation, unsatisfactory catalytic effect, difficult recovery of catalyst, etc., to improve catalytic performance. Effect, stable product quality, reducing the effect of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

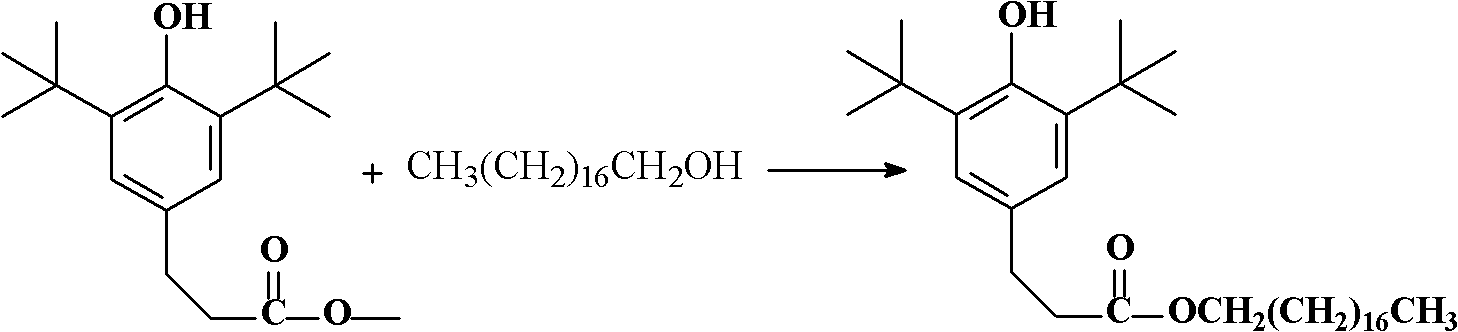

Method used

Image

Examples

Embodiment 1

[0017] Add 3g of porous hydroxyapatite to 0.05mol / L Sr(NO 3 ) 2 The solution was mechanically stirred at room temperature for 4 hours, filtered, and the obtained solid was dried at 100°C for 4 hours, and then burned at 400°C for 8 hours to obtain the self-made solid base catalyst of the present invention.

[0018] In a reactor equipped with heating, stirring, thermometer, water separator and reflux condensing device, 58.4 g of methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate were added at room temperature g (0.2mol) and 54.1g (0.2mol) of stearyl alcohol, 3.0g of the solid base catalyst prepared above, gradually heated up to 100°C while stirring, reacted for 2.0 hours, cooled the reaction solution to room temperature, added 200mL of ethanol, and filtered Recover the solid base catalyst (recyclable after recovery), the filtrate was stirred and cooled at 15°C for 2h, and filtered to obtain 92.73g of white solid, which is the target product of the present invention, antiox...

Embodiment 2

[0020] Add 30g of porous hydroxyapatite to 0.05mol / L tetramethylammonium hydroxide solution, stir mechanically at room temperature for 8h, filter, dry the obtained solid at 100°C for 4h, and then burn at 400°C for 10h to obtain The self-made solid base catalyst of the present invention.

[0021] In a reactor equipped with heating, stirring, thermometer, water separator and reflux condensing device, 58.4 g of methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate were added at room temperature g (0.2mol) and 59.51g (0.22mol) of stearyl alcohol, 5g of the solid base catalyst prepared above, gradually heated up to 130°C while stirring, reacted for 5.0 hours, cooled the reaction solution to room temperature, added 200mL of ethanol, and recovered by filtration Solid base catalyst (can be recycled after recovery), the filtrate was stirred and cooled at 15°C for 3h, and 100.56g of white solid was filtered, which was the target product of the present invention, antioxidant 1076, with...

Embodiment 3

[0023] Add 30 g of porous hydroxyapatite into 0.05 mol / L potassium hydroxide solution, stir mechanically at room temperature for 12 h, and filter. The obtained solid was dried at 100° C. for 4 hours, and then burned at 500° C. for 12 hours to obtain the self-made solid base catalyst of the present invention.

[0024] In a reactor equipped with heating, stirring, thermometer, water separator and reflux condensing device, 58.4 g of methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate were added at room temperature g (0.2mol) and 64.92g (0.24mol) of octadecyl alcohol, 8g of the solid base catalyst prepared above, gradually heated up to 110°C while stirring, reacted for 3.0 hours, cooled the reaction solution to room temperature, added 200mL of ethanol, and recovered by filtration Solid base catalyst (recyclable after recovery), the filtrate was stirred and cooled at 15°C for 4h, filtered to obtain 95.65g of white solid, which is the target product of the present invention, ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com