Integrated multifunctional chimney-free low-carbon gas boiler

A gas-fired boiler, no chimney technology, applied in the field of boilers, can solve the problems of secondary pollution of pipelines, tar blockage, large emission of flue gas and dust, and achieve the effects of improving combustion efficiency, reducing floor space and reducing exhaust gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the structure of the present invention will be further described:

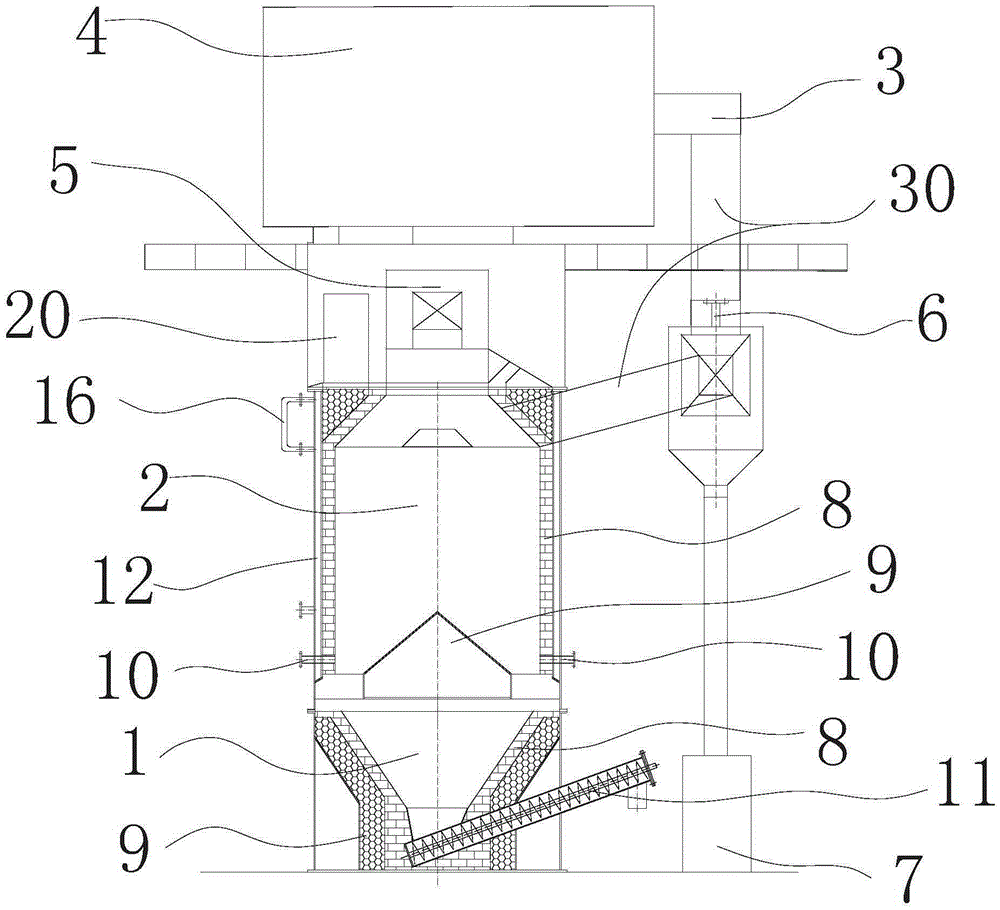

[0021] An integrated multifunctional smokeless low-carbon gas boiler, such as figure 1 As shown, it includes a vertically placed cylindrical furnace body. The furnace body includes an ash bin 1 and a gasification chamber 2. The gasification chamber 2 and the ash bin 1 are combined up and down to form a biomass gasification furnace. The gasification chamber of the furnace body A boiler 4 is installed on the upper side of the furnace body, a feeding device 5 is installed on the top of the gasification chamber 2 of the furnace body, and a combustor 3 capable of burning biomass gas or natural gas is installed on one side of the boiler 4. The gasification chamber 2 The top is also connected with a pipeline 30 that facilitates the supply of gas generated to the burner 3; wherein, the burner 3 can burn biomass gas and natural gas at the same time, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com