N-type double-side battery and manufacturing method thereof

A double-sided battery and a manufacturing method technology, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

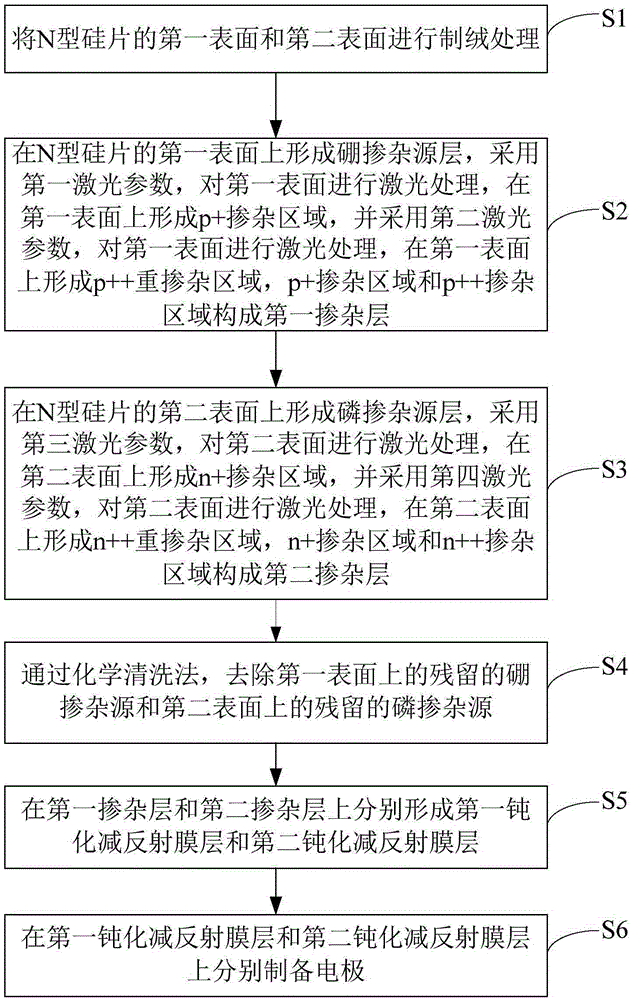

Method used

Image

Examples

Embodiment 1

[0060] Put the N-type silicon chip 110 into the texturizing additive for reaction, control the reaction temperature to 80°C, and the reaction time to 20 minutes, so that the first surface and the second surface of the N-type silicon chip 110 both have a pyramid-shaped textured structure, making The velvet additive is: the mass ratio of alkali, isopropanol, additive and water is 2.5:10:0.5:87;

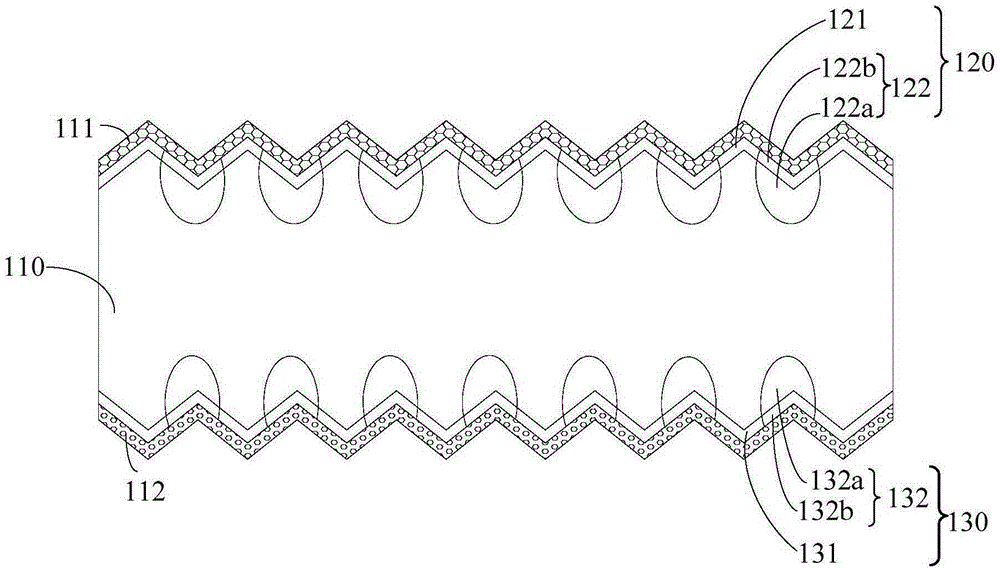

[0061] Spin-coat 0.5 g of boron-containing silicon oxide solution on the first surface of the N-type silicon wafer 110, and dry it. After drying, the entire surface of the first surface is scanned by laser. The laser scanning condition is: 532nm green light pulse Laser, 18W power, 1.2m / s scanning speed and 50 micron spot diameter, form a p+ doped layer on the first surface, the sheet resistance of the p+ doped layer is 50Ω / □, and the thickness of the p+ doped layer is 0.4 micron, Next, the specific area on the first surface is repeatedly scanned by laser. The conditions for repeated las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com