Organic/inorganic composite polymer diaphragm and preparation method thereof

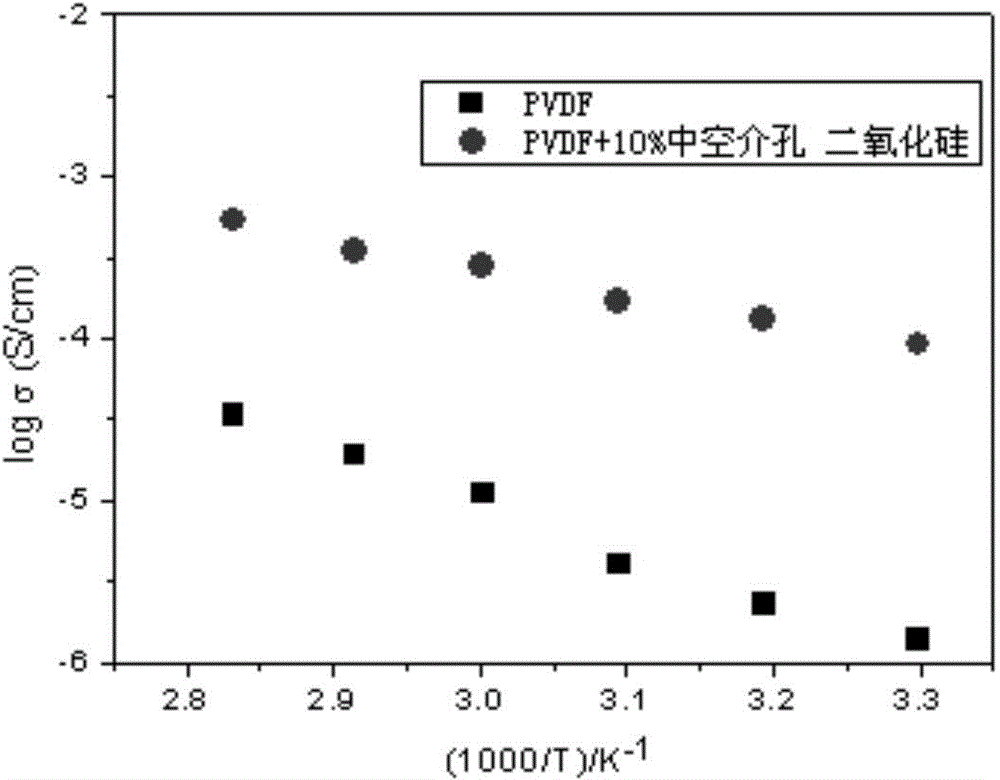

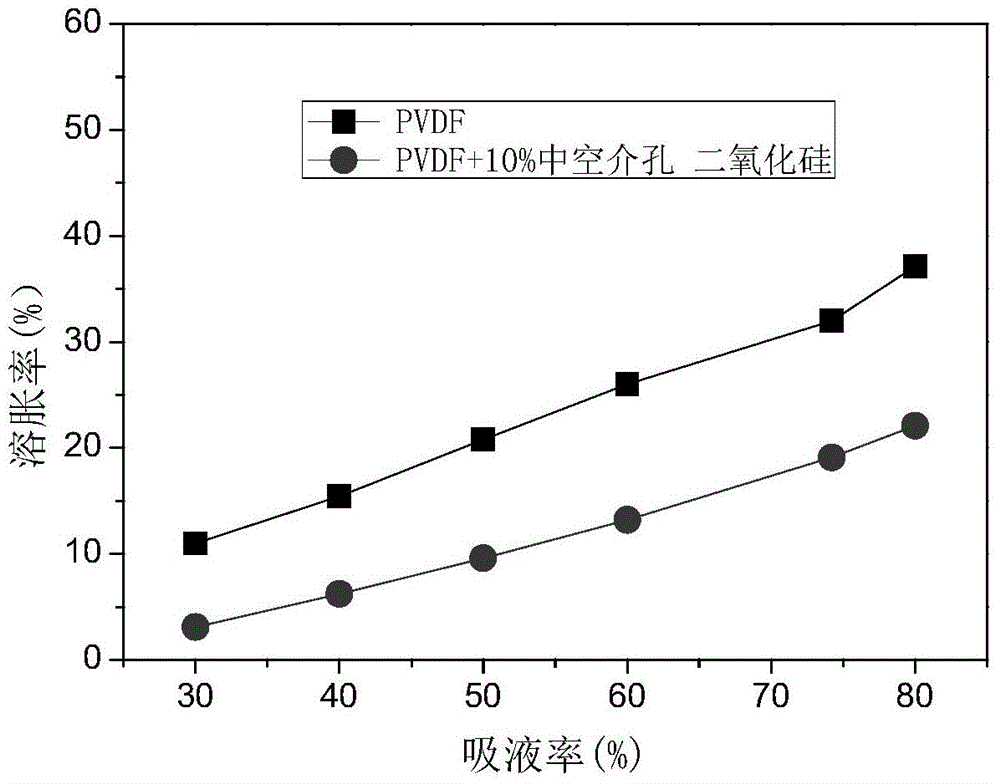

An inorganic composite and polymer technology, applied in electrical components, circuits, battery pack parts, etc., can solve the problems of low swelling rate and high swelling rate, and achieve the advantages of reducing swelling rate, improving electrical conductivity and increasing liquid absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

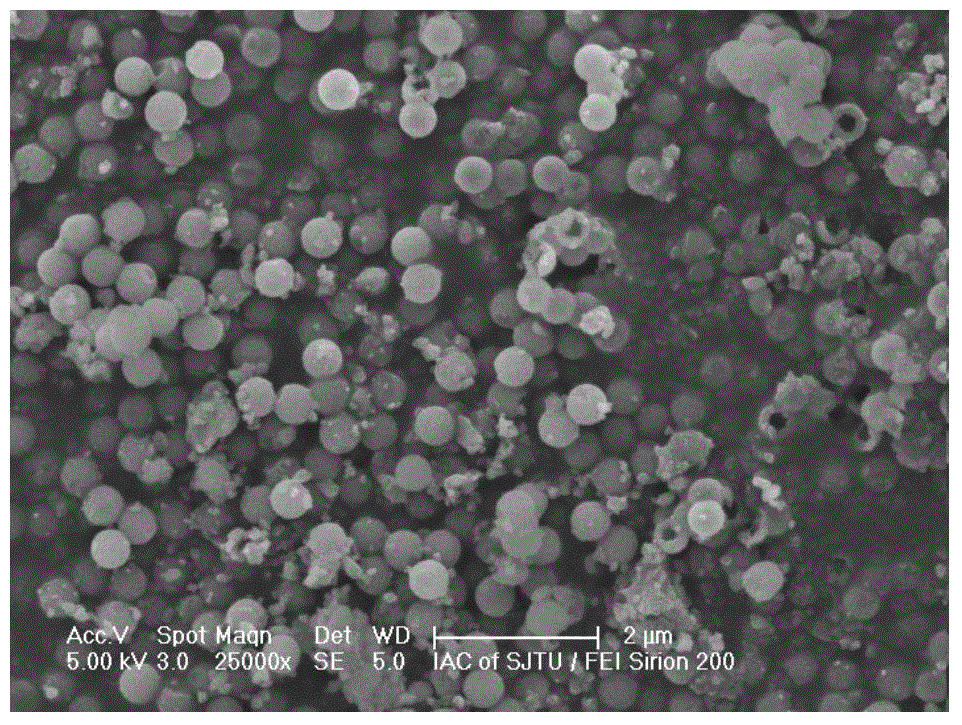

[0063] This embodiment relates to an organic / inorganic composite polymer membrane, including a polymer matrix and hollow mesoporous silica microspheres, the hollow mesoporous silica microspheres are dispersed in the polymer matrix, and the hollow mesoporous silica microspheres Balls (the average outer diameter of hollow mesoporous silica microspheres is 100-2000nm, the average wall thickness is 0.1-0.4 times the outer diameter, and the wall part has an ordered mesoporous structure along the direction perpendicular to the spherical surface) and poly The mass ratio of vinyl fluoride is 1:100; the average pore diameter of the mesopores is 2-10nm, and the mesopores run through the entire wall of the hollow mesoporous silica microspheres, so that the absorbed liquid substances can enter the cavity part of the microspheres.

[0064] This embodiment also relates to the preparation method of the aforementioned organic / inorganic composite polymer diaphragm, comprising the following step...

Embodiment 2

[0070] This embodiment relates to an organic / inorganic composite polymer membrane, including a polymer matrix and hollow mesoporous silica microspheres, the hollow mesoporous silica microspheres are dispersed in the polymer matrix, and the hollow mesoporous silica microspheres Balls (the average outer diameter of hollow mesoporous silica microspheres is 100-2000nm, the average wall thickness is 0.1-0.4 times the outer diameter, and the wall part has an ordered mesoporous structure along the direction perpendicular to the spherical surface) and polyoxidized The mass ratio of ethylene is 1:100; the average pore diameter of the mesopores is 2-10nm, and the mesopores run through the entire wall of the hollow mesoporous silica microspheres, so that the absorbed liquid substances can enter the cavity part of the microspheres.

[0071] This embodiment also relates to the preparation method of the aforementioned organic / inorganic composite polymer diaphragm, comprising the following st...

Embodiment 3

[0077] This embodiment relates to an organic / inorganic composite polymer membrane, including a polymer matrix and hollow mesoporous silica microspheres, the hollow mesoporous silica microspheres are dispersed in the polymer matrix, and the hollow mesoporous silica microspheres Balls (the average outer diameter of hollow mesoporous silica microspheres is 100-2000nm, the average wall thickness is 0.1-0.4 times the outer diameter, and the wall part has an ordered mesoporous structure along the direction perpendicular to the spherical surface) and polypropylene The mass ratio of nitrile is 1:50; the average pore diameter of the mesopores is 2-10nm, and the mesopores run through the entire wall of the hollow mesoporous silica microspheres, so that the absorbed liquid substances can enter the cavity part of the microspheres.

[0078] This embodiment also relates to a method for preparing the aforementioned organic / inorganic composite polymer membrane, comprising the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average outer diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com