Three-dimensional porous graphene-supported carbon-coated lithium sulfide cathode material as well as preparation method and application thereof

A three-dimensional porous, positive electrode material technology, applied in the direction of battery electrodes, electrochemical generators, electrical components, etc., can solve problems such as troublesome operation, achieve the effects of maintaining stability, improving electrical conductivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

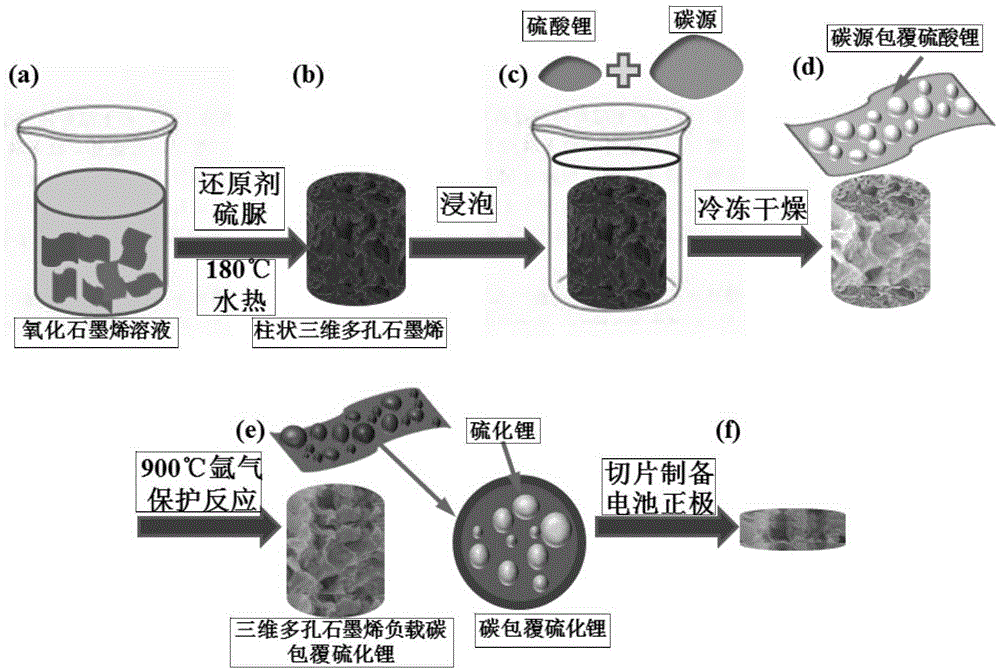

[0030] (1) Disperse graphene oxide in 140g deionized water with magnetic stirring, and ultrasonically 1h to form a uniform and stable solution, the concentration of graphene oxide in the graphene oxide solution is 2mg / ml, then add reducing agent thiourea and stir to dissolve, Obtain a brown solution, the concentration of reducing agent thiourea in the brown solution is 1.5mg / mL;

[0031] (2) Transfer the brown solution obtained above to an autoclave, seal the autoclave and place it at 180° C. for 10 hours, then wait for the temperature of the autoclave to drop to room temperature 25° C. to obtain a columnar three-dimensional porous graphene solution ;

[0032] (3) add lithium sulfate monohydrate and glucose in the solution of the columnar three-dimensional porous graphene of gained, after stirring and dissolving, columnar three-dimensional porous graphene is soaked wherein, form the soaking liquid of columnar three-dimensional porous graphene, the columnar three-dimensional poro...

Embodiment 2

[0041] (1) Disperse graphene oxide in 140g deionized water with magnetic stirring, and ultrasonically 1h to form a uniform and stable solution, the concentration of graphene oxide in the graphene oxide solution is 3mg / ml, then add reducing agent thiourea and stir to dissolve, Obtain a brown solution, and the concentration of reducing agent thiourea in the brown solution is 5 mg / mL;

[0042] (2) Transfer the brown solution obtained above to an autoclave, seal the autoclave and place it at 180° C. for 10 hours, then wait for the temperature of the autoclave to drop to room temperature 25° C. to obtain a columnar three-dimensional porous graphene solution ;

[0043] (3) Add lithium sulfate and polyvinylpyrrolidone with a number average molecular weight of 58,000 to the obtained columnar three-dimensional porous graphene and the solution, and soak the columnar three-dimensional porous graphene to obtain the soaking solution of columnar three-dimensional porous graphene, columnar t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com