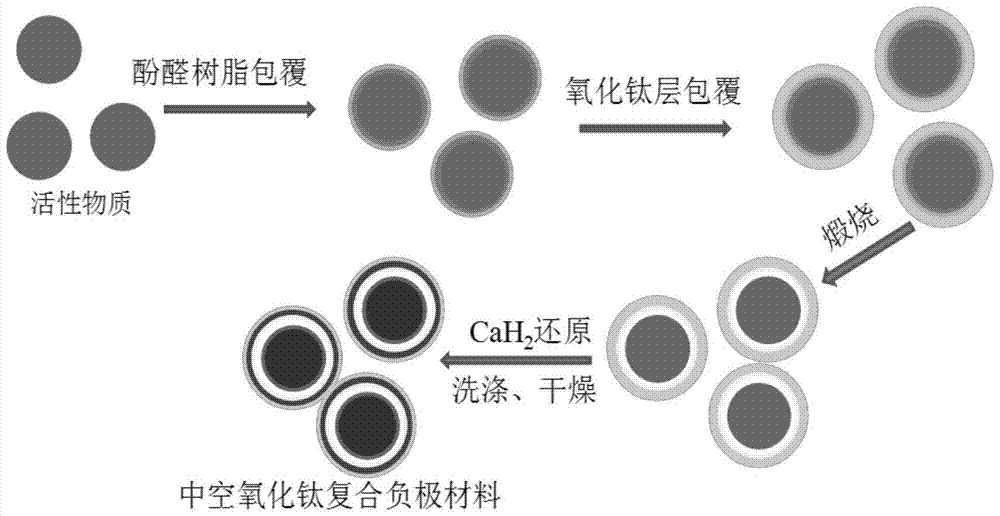

A kind of hollow titanium oxide composite material, preparation method and application

A composite material and titanium oxide technology, applied in the field of composite materials, can solve problems such as electrode deformation and poor cycle stability, and achieve the effects of improved electrochemical performance, excellent charge and discharge performance, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

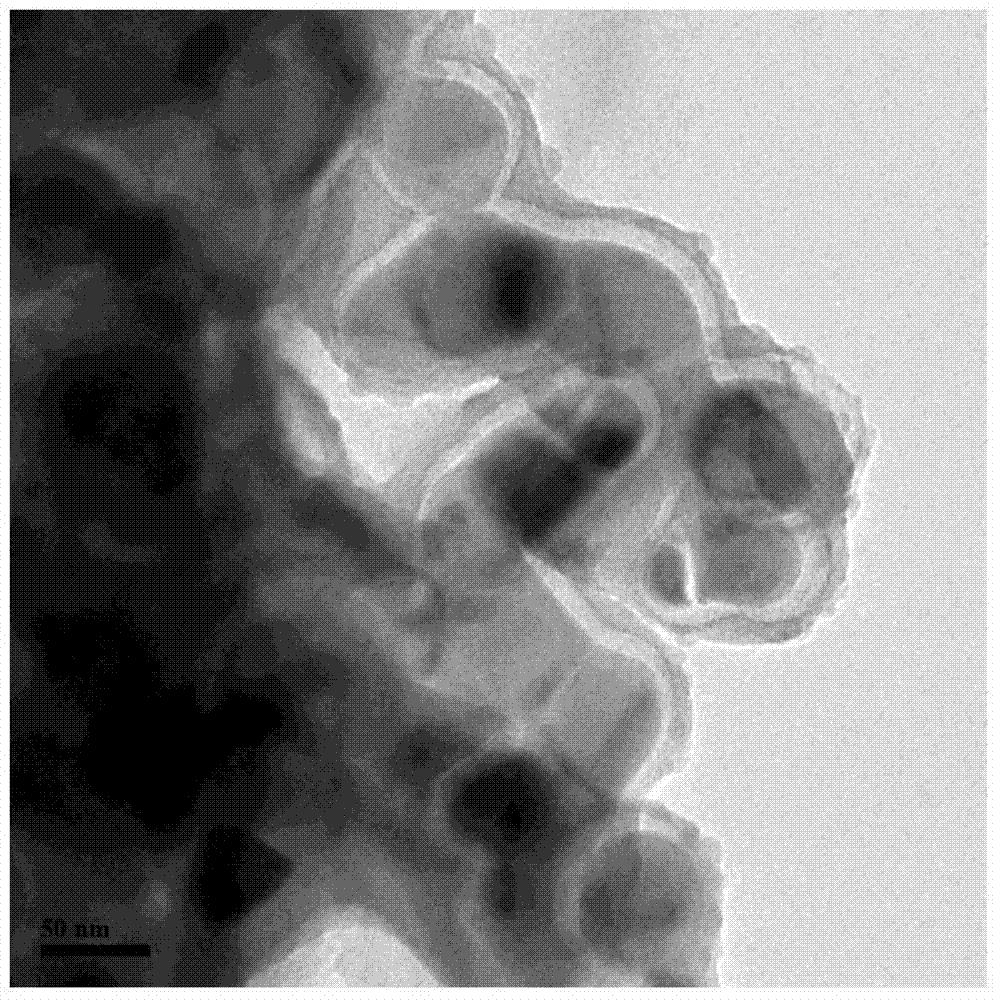

Examples

Embodiment 1

[0034] 28.6 mL of deionized water and 71.4 mL of ethanol were prepared into a mixed solution, stirred evenly by ultrasonic, 0.2 g of Si nanoparticles were taken, dispersed in it and stirred by ultrasonic for 1 h. Add 1.2g of cetyltrimethylammonium bromide (CTAB), 0.175g of resorcinol and 0.1mL of ammonia water to the above mixed solution, stir ultrasonically for 30min, then place in an oil bath at 45°C and stir for 30min , add 0.15mL formaldehyde solution, continue to stir at 45°C for 24h, then turn off the oil bath heating switch, filter with suction, wash 3 times with deionized water, and dry in vacuum at 70°C for 3h to prepare Si nanoparticles coated with phenolic resin layers of composite material.

[0035] Take 0.15g of the Si composite material coated with a phenolic resin layer, ultrasonically disperse it in 200ml of absolute ethanol for 30min, add 0.5mL of 28wt% concentrated ammonia water, ultrasonically for 5min, then transfer to a 500mL round-bottomed flask, place in...

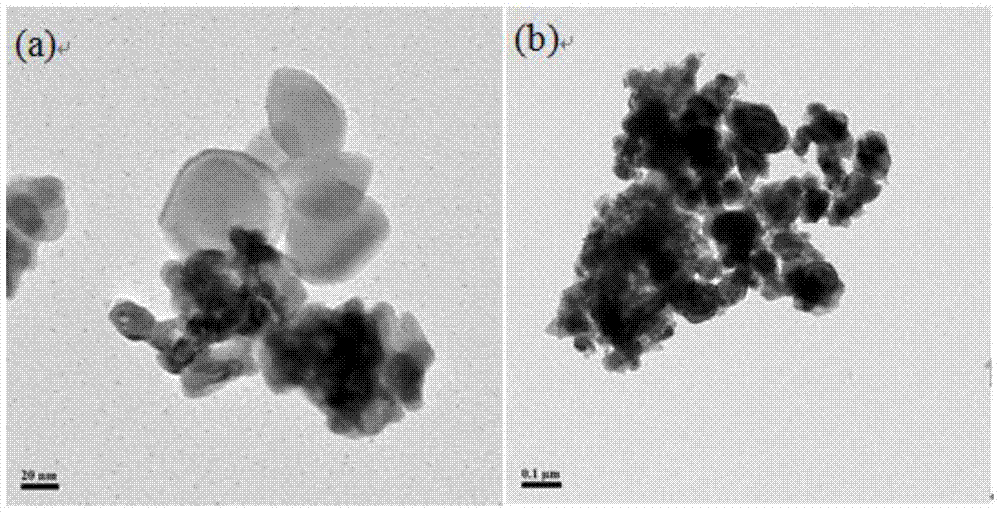

Embodiment 2

[0040] Prepare a mixed solution of 28.6mL deionized water and 71.4mL ethanol, stir it evenly by ultrasonic, take 0.2g In 2 o 3 nanoparticles, dispersed therein and ultrasonically stirred for 1 h. Add 1.2g CTAB, 0.175g resorcinol and 0.1mL ammonia water to the above mixed solution, stir ultrasonically for 30min, then place in an oil bath and stir for 30min at 45°C, add 0.15mL formaldehyde solution, continue at 45°C Stir for 5h, then turn off the oil bath heating switch, filter with suction, wash 3 times with deionized water, and vacuum dry at 70°C for 3h to prepare In 2 o 3 Nanoparticles coated with phenolic resin layer of In 2 o 3 composite material.

[0041] Take 0.15g of In covered with phenolic resin layer 2 o 3 The composite material was ultrasonically dispersed in 200ml of absolute ethanol for 30min, 0.5mL of 28wt% concentrated ammonia water was added, ultrasonicated for 5min, then transferred to a 500mL round-bottomed flask, magnetically stirred in an oil bath, an...

Embodiment 3

[0046] Prepare a mixed solution with 28.6mL of deionized water and 71.4mL of ethanol, and stir it evenly by ultrasonic. Take 0.2g of nano SnO 2 Balls, dispersed in which ultrasonic stirring for 1h. Add 1.2g CTAB, 0.175g resorcinol, and 0.1mL ammonia water to the above solution, and stir ultrasonically for 30min. Then put it in an oil bath at 45°C and stir for 30min, add 0.15mL of formaldehyde solution, keep stirring at 45°C for 5h, turn off the oil bath heating switch, filter with suction, wash with deionized water 3 times, and vacuum dry at 70°C for 3h , to prepare SnO coated with phenolic resin layer 2 composite material.

[0047] Get 0.15g of SnO coated with phenolic resin layer 2 The composite material was ultrasonically dispersed in 200ml of absolute ethanol for 30min, 0.5mL of 28wt% concentrated ammonia water was added, and ultrasonicated for 5min. Then transfer to a 500mL round bottom flask, place in an oil bath and use magnetic stirring, add 1.5mL tetrabutyl titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com