A kind of preparation method of metal oxide conductive powder composite lithium titanate material

A technology for oxide conduction and composite lithium titanate, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as increasing the contact area between electrode materials and electrolyte, aggravating the flatulence of lithium titanate batteries, and large specific surface areas of materials , to achieve obvious electrochemical performance, improve environmental and electrical conductivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

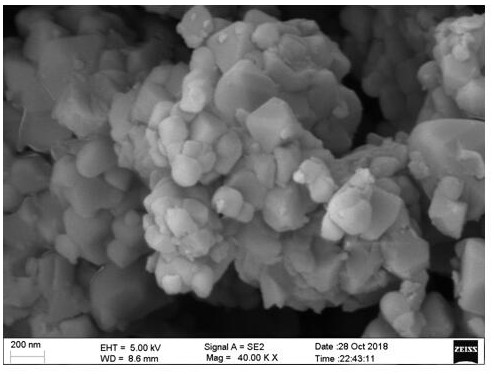

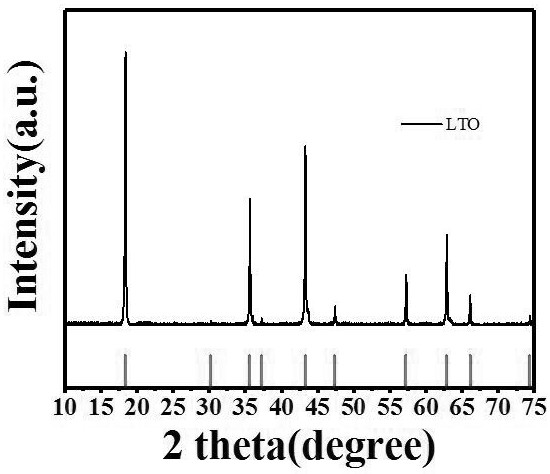

Image

Examples

Embodiment 1

[0029] The preparation method of the metal oxide conductive powder composite lithium titanate material in this embodiment includes the following steps:

[0030] (1) According to Li 4 Ti 5 O 12 Lithium hydroxide (D50=65nm, excess lithium 3%) and titanium dioxide (D50=80nm) were weighed in stoichiometric ratio, poured into a ball mill jar, and dry mixed in a 360-degree three-dimensional rotation (20r / min in the vertical direction, 300r / min in the horizontal direction). min) 3h, put the mixed precursor in a muffle furnace and raise the temperature to 800°C at a heating rate of 2°C / min, keep for 8 h, cool naturally, and then vibrate and sieve (400 mesh) after grinding to obtain D50 = 0.3 μm lithium titanate material;

[0031] (2) Weigh Sb according to the ratio of n(Sb):n(Sn) = 1.1% 2 O 3 and SnO 2 , pour it into the agate ball mill jar, add deionized water and agate balls (the ratio of balls to material is 5:1), prepare the solid content to reach 40%, put it on the ball mil...

Embodiment 2

[0034] The preparation method of the metal oxide conductive powder composite lithium titanate material in this embodiment includes the following steps:

[0035] (1) According to Li 4 Ti 5 O 12 Lithium carbonate (D50=2.5μm, excess lithium 7%) and titanium dioxide (D50=1.3μm) were weighed in a stoichiometric ratio, poured into a ball mill jar, and dry mixed in a 360-degree three-dimensional rotation (20r / min in the vertical direction and 200r in the horizontal direction). / min) for 12h, put the mixed precursor in a muffle furnace and raise the temperature to 800°C at a heating rate of 5°C / min, keep for 16 h, cool down naturally, and then vibrate and sieve (400 mesh) after grinding to obtain D50 = 2.2 μm lithium titanate material;

[0036] (2) Weigh Sb according to the ratio of n(Sb):n(Sn) = 2.1% 2 O3 and H 3 SnO 3 , pour it into the agate ball mill jar, add ethanol and agate balls (the ratio of ball to material is 4:1), prepare the solid content to reach 55%, put it on the...

Embodiment 3

[0039] The preparation method of the metal oxide conductive powder composite lithium titanate material in this embodiment includes the following steps:

[0040] (1) According to Li 4 Ti 5 O 12 Lithium hydroxide (D50=0.65μm, excess lithium 5%) and titanium dioxide (D50=1.2μm) were weighed in the stoichiometric ratio, poured into a ball mill jar, and dry mixed in a 360-degree three-dimensional rotation (20r / min in the vertical direction and 20 r / min in the horizontal direction). 200r / min) for 10h, put the mixed precursor in a muffle furnace and raise the temperature to 800°C at a heating rate of 5°C / min, keep it for 10 h, cool it naturally, and then vibrate and sieve (400 mesh) after grinding to obtain D50 = 0.53μm lithium titanate material;

[0041] (2) Weigh Sb according to the ratio of n(Sb):n(Sn) = 2% 2 O 3 and Sn(NO 3 ) 2 , pour it into the agate ball mill jar, add ethylene glycol and agate balls (the ratio of balls to material is 5:1), prepare the solid content to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com