A new type of silicon monoxide-based negative electrode material for lithium-ion batteries and its preparation method and application

A lithium-ion battery, silicon monoxide-based technology, applied in the field of lithium-ion batteries, can solve the problems of the first discharge capacity to be improved, technical operation complexity, etc., and achieve the effect of easy promotion and use, abundant raw material sources, and buffer volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The silicon monoxide-based negative electrode material of the present embodiment, the material that adopts has polyacrylonitrile (PAN) and silicon monoxide nanoparticle

[0062] (1) Dissolve PAN and silicon monoxide nanoparticles in N,N-dimethylformamide (NMP for short) organic solvent with a mass ratio of 3:7 at a ratio of 1:20 (mass ratio of solute to solvent), and ultrasonically After 1 h of treatment, magnetic stirring was carried out at room temperature for 12 h to obtain a mixed solution.

[0063] (2) The solution obtained in step 1) was volatilized until it became viscous, then sonicated again for 1 hour, and then spread evenly on the copper foil to obtain a pole piece.

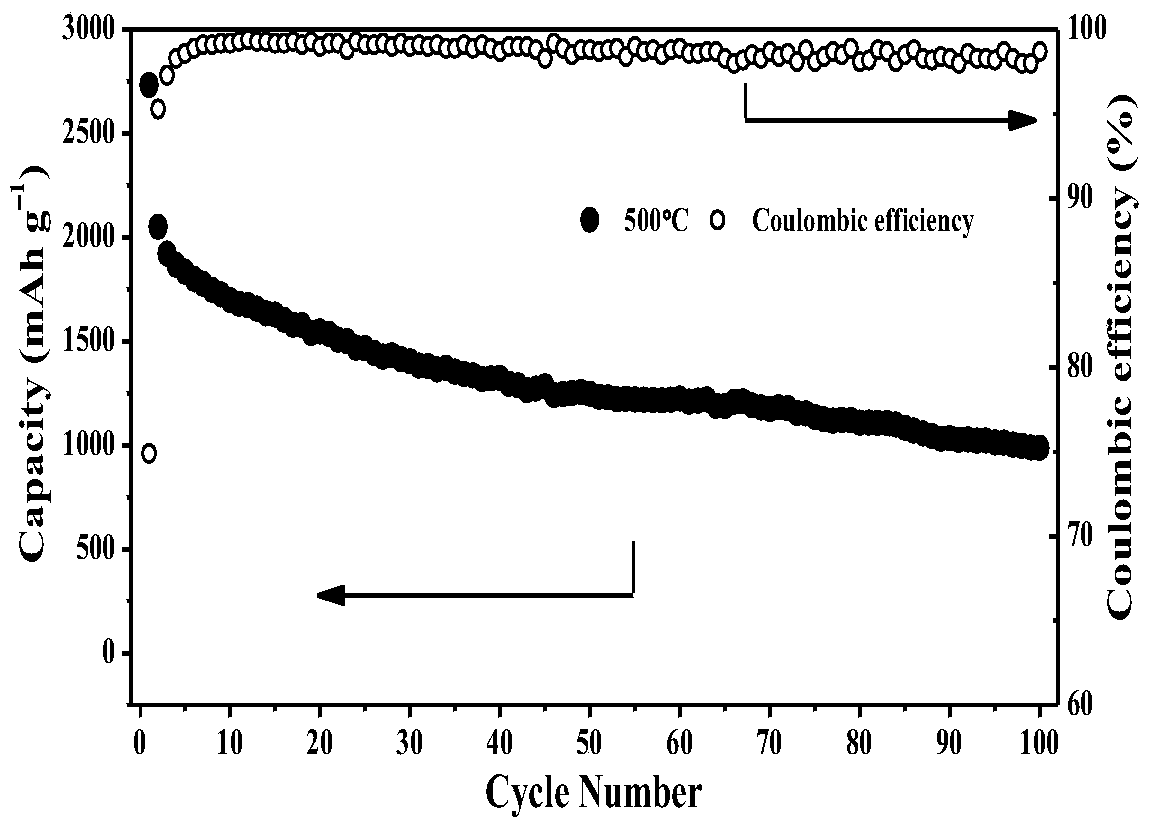

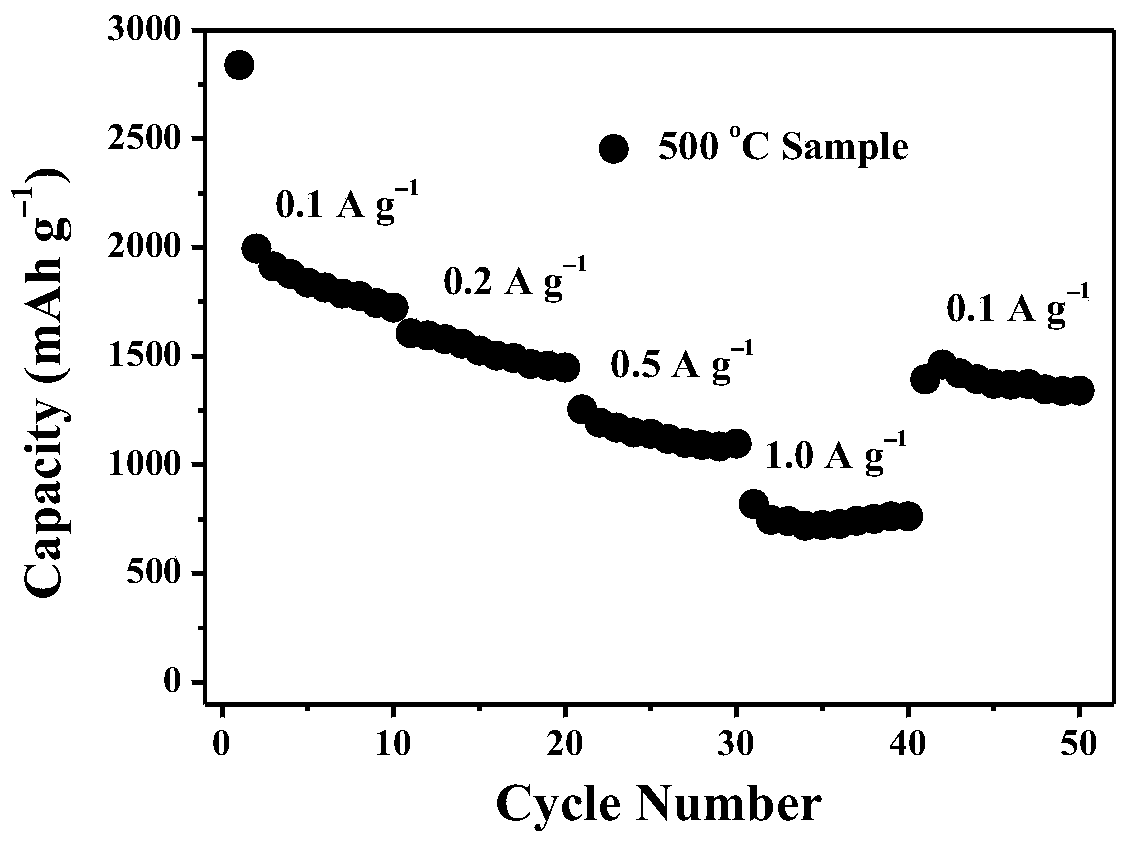

[0064] (3) Place the pole piece obtained in step 2) in a tube furnace for calcination under the protection of an argon atmosphere, at a temperature of 500°, for 12 hours (heating rate 5° / min), and after cooling down to room temperature, the PAN@SiO-based Negative material.

[0065] The final p...

Embodiment 2-5

[0070] The silicon monoxide-based negative electrode material was prepared by the same method as in Example 1, except that PAN was replaced by 5-chlorovaleronitrile, 3-chloro-5-hydroxybenzonitrile, acrylic acid and aniline, respectively.

[0071] Compound and product number used in table 1 embodiment 2-5

[0072]

compound

product number

Example 2

5-chlorovaleronitrile

CNCl@SiO

Example 3

3-Chloro-5-hydroxybenzonitrile

CNOCl@SiO

Example 4

acrylic

CO@SiO

Example 5

CN@SiO

[0073] Adopt the same method as in Example 1 to measure the half-battery cycle of the lithium-ion battery with CNCl@SiO, CNOCl@SiO, CO@SiO, CN@SiO-based negative electrode materials to 50 cycle performance curves, and embodiment 1 The results are similar for PAN@SiO-based anode materials. It has been confirmed that the above-mentioned negative electrode material can maintain the contact stability of the active material on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com