Preparation method of lithium iron phosphate/carbon nanotube microsphere cathode material, optimization method of cathode material and aqueous lithium ion capacitor

A carbon nanotube microsphere, lithium iron phosphate technology, applied in the field of electrochemical energy storage, can solve problems such as easy agglomeration, limited ion diffusion, etc., and achieve the effects of no pollution, environmental friendliness, and stable crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

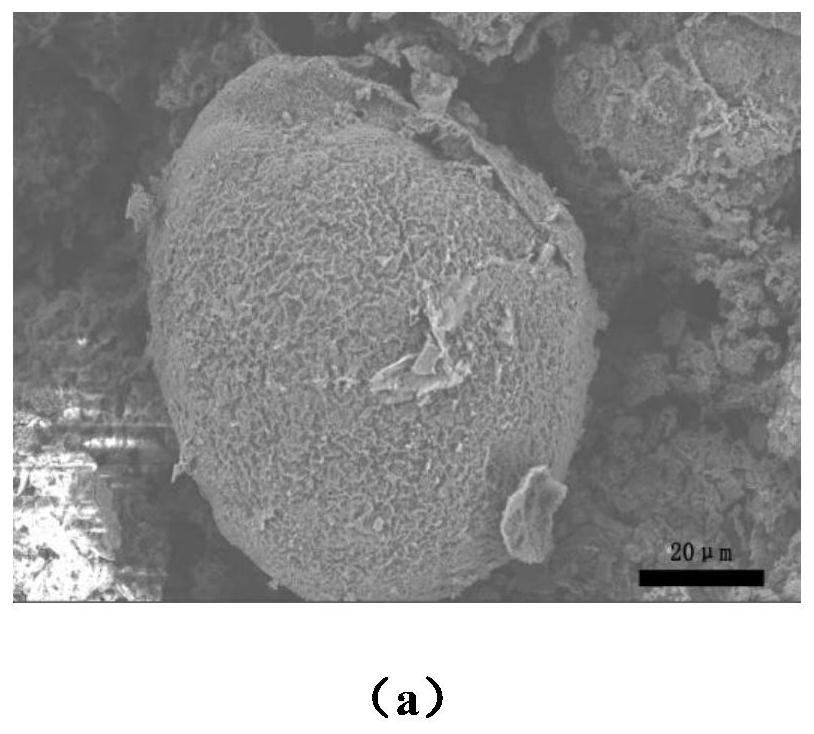

[0044] Example 1 Preparation of lithium iron phosphate / carbon nanotube microsphere positive electrode material

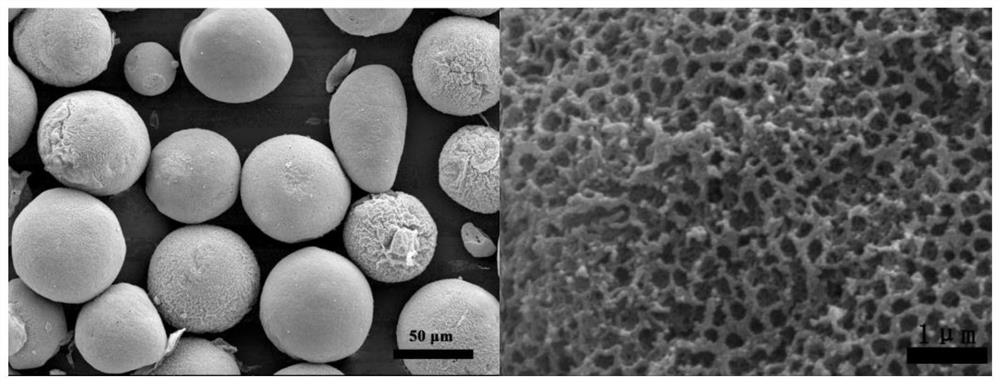

[0045] (1) Preparation of carbon nanotube microspheres by template method:

[0046] 1) Preparation of hydroxylated polystyrene microspheres:

[0047] At a stirring speed of 300r / min, 200mL of deionized water, 100mL of styrene and 2mL of α-methacrylic acid were mixed, heated and condensed to reflux under stirring, and then 0.5g of potassium persulfate aqueous solution with a concentration of 5wt% was added as an initiator. After 2h reaction, the product was obtained. The product was centrifuged at 10,000 rpm for 20 minutes, the supernatant was discarded, the precipitate was washed with absolute ethanol, then with deionized water, and dried to obtain hydroxylated polystyrene microspheres;

[0048] 2) Preparation of acidified carbon nanotubes:

[0049] Place carbon nanotubes in mixed acid, ultrasonically treat for 30 minutes, and then react in an oil bath at 60°C at...

Embodiment 2

[0060] The preparation of embodiment 2 water-based lithium ion capacitors

[0061] 1. The preparation of lithium ion capacitor positive plate: get respectively 5mg, 10mg, 15mg lithium iron phosphate / carbon nanotube microsphere positive electrode material prepared in embodiment 1, add conductive agent carbon black and binder polytetrafluoroethylene solution, Mix evenly, coat on the front and back sides of the treated foam nickel, the coating area is 1cm×1cm, and then put it in an oven with a temperature of 60°C for 24h, and roll it into a 0.5mm thick Sheet form, leaving the coating material exposed on both sides;

[0062] The quality of the conductive agent carbon black is 10%, 20%, 30% and 40% of the total mass of the conductive agent carbon black and lithium iron phosphate / carbon nanotube microsphere positive electrode material, and the binder polytetrafluoroethylene solution is 4wt % polytetrafluoroethylene aqueous solution, the quality of polytetrafluoroethylene in the bin...

PUM

| Property | Measurement | Unit |

|---|---|---|

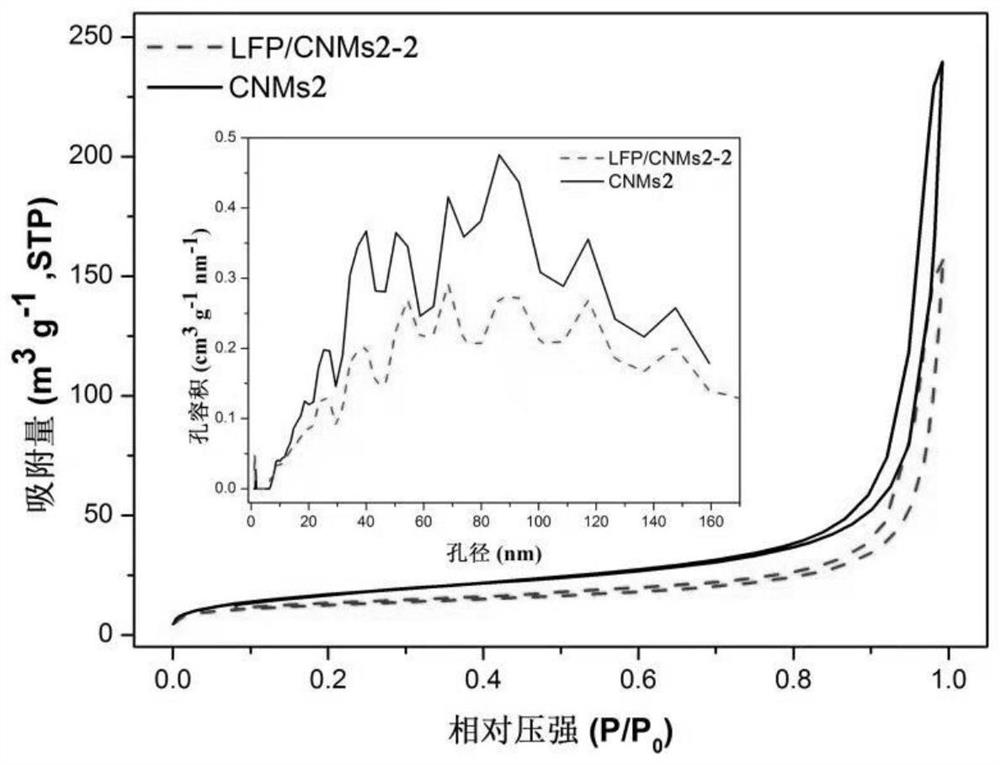

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com