Modified one-dimensional TiNb24O62 as well as preparation method and application thereof

A modification and niobium source technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve problems such as cumbersome synthesis process, unsuitable for industrial scale application, and unsatisfactory electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a modified one-dimensional TiNb 24 o 62 The preparation method comprises the following steps:

[0031] Mix polyvinylpyrrolidone, N,N-dimethylformamide and acid solution to obtain dispersant A;

[0032] Mixing the niobium source, the titanium source and the dispersant A to obtain a B solution;

[0033] After the B solution is electrospun, the obtained product is first calcined to obtain a one-dimensional TiNb 24 o 62 ;

[0034] The one-dimensional TiNb 24 o 62 Carrying out the second calcination to obtain the modified one-dimensional TiNb 24 o 62 .

[0035] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0036] In the present invention, polyvinylpyrrolidone, N,N-dimethylformamide and acid solution are mixed to obtain dispersant A; in the present invention, the mixing is preferably to add the polyvinylpyrrolidone to N,N-dimethylf...

Embodiment 1

[0051] Dissolve 3.3g of polyvinylpyrrolidone in a mixture of 20mL N,N-dimethylformamide and 2mL of acetic acid to obtain Dispersant A;

[0052] Mix 4.7635g of niobium pentachloride with dispersant A, stir for 3h, add 251μL of tetrabutyl titanate dropwise, and continue stirring for 1h to obtain solution B (the molar ratio of Ti to Nb is 1:24);

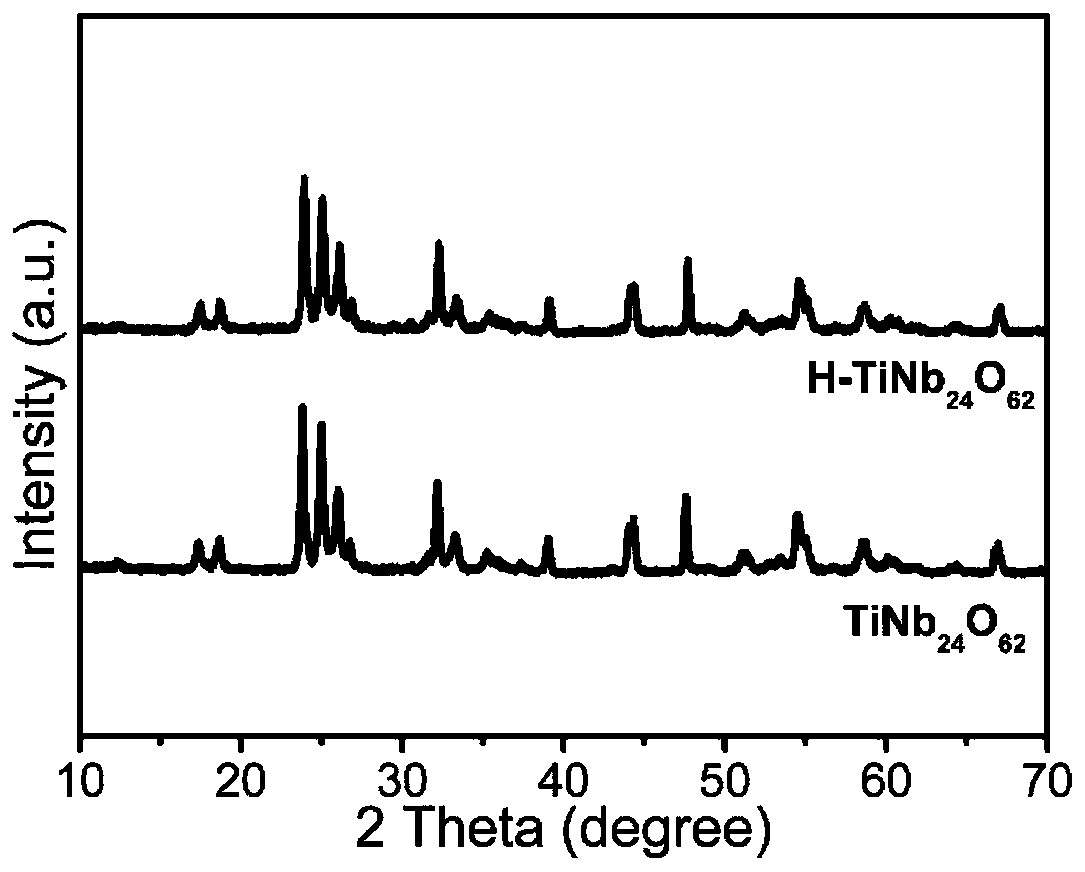

[0053] The B solution was transferred to the electrospinning syringe, and after electrospinning (needle type: 21G, distance between the needle and the receiving plate was 15cm, voltage 20kV, advancing speed 0.01mm / min), the obtained product was subjected to the first Calcination (nitrogen atmosphere, temperature 850°C, time 4h) to obtain one-dimensional TiNb 24 o 62 ;

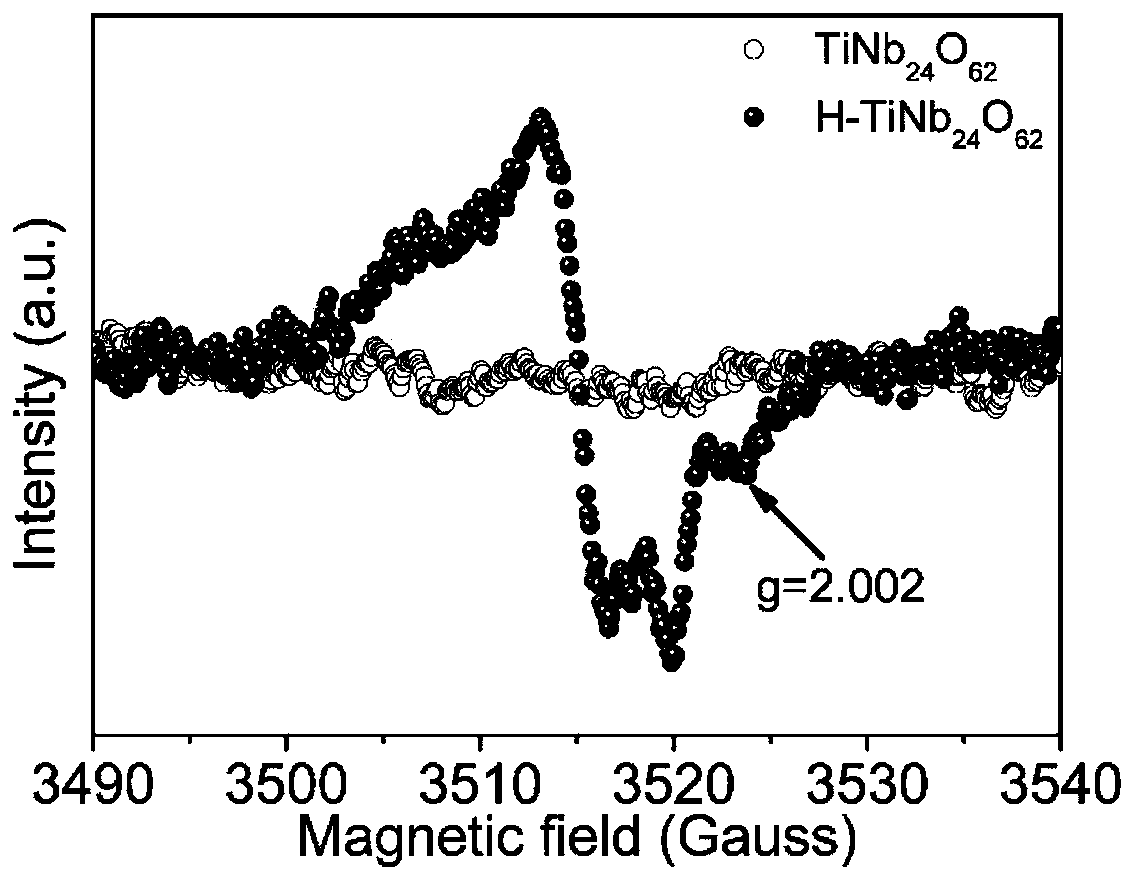

[0054] The one-dimensional TiNb 24 o 62 Carry out the second calcination (hydrogen atmosphere, temperature 700°C, time 1h) to obtain modified one-dimensional TiNb 24 o 62 (Denoted as H-TiNb 24 o 62 );

[0055] The one-dimensional TiNb prepared in this embodiment...

Embodiment 2

[0059] The preparation reference example 1 of B solution;

[0060] The B solution was transferred to the electrospinning syringe, and after electrospinning (needle type: 21G, distance between the needle and the receiving plate was 15cm, voltage 15kV, advancing speed 0.01mm / min), the obtained product was subjected to the first Calcination (nitrogen atmosphere, temperature 850°C, time 4h) to obtain one-dimensional TiNb 24 o 62 ;

[0061] The one-dimensional TiNb 24 o 62 Carry out the second calcination (hydrogen atmosphere, temperature 700°C, time 1h) to obtain modified one-dimensional TiNb 24 o 62 ;

[0062] The electrochemical test process refers to Example 1, and the test result is: the modified one-dimensional TiNb 24 o 62 at 0.1Ag -1 The reversible specific capacity can reach 280mA·h·g under the current density -1 , and at 1A·g -1 After 100 cycles at the current density, the retention rate of its specific capacity can reach 90.0%, and it has more excellent rate p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com