Lithium ion battery containing high-thermal-conductivity and high-conductivity phase change composite material and conductive agent

A phase change composite material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow heat dissipation, battery life impact, insecurity, etc., achieve high thermal conductivity and high electrical conductivity, and avoid safety. Hidden danger, effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the lithium-ion battery containing the high-conductivity and high-thermal-conduction phase-change composite material provided by the present invention comprises the following steps:

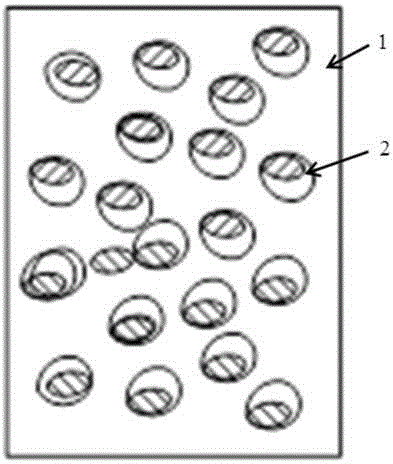

[0033] Step 1, add the phase change material into the graphene oxide solution, heat until the phase change material melts, and then ultrasonically disperse for 2~4 hours to obtain a stable emulsion of graphene oxide wrapped phase change material, and then add sulfuric acid to the above emulsion to adjust the pH to 2 ~3, make graphene oxide condense, cool to form capsules and separate out to obtain graphene oxide phase-change nanocapsules, the capsule wall of which is graphene oxide, and the core material is phase-change material; the size of the phase-change nanocapsules is 20 ~80nm;

[0034] Step 2, dissolve the nano-phase-change capsules in water, then add a certain amount of porous graphene, and disperse by ultrasonic for 5-10 hours, so that the nano-phase-chan...

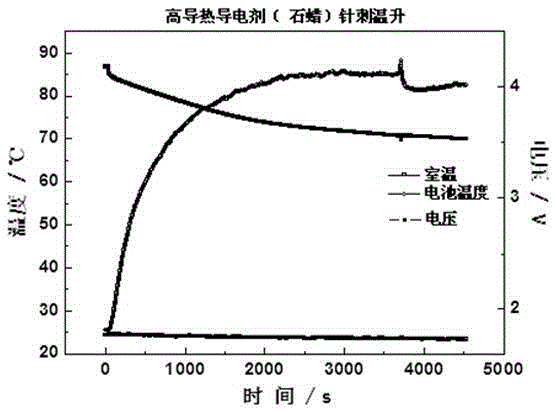

Embodiment 1

[0038] Add 300g of paraffin to 1L of 0.5g / l graphene oxide solution, heat at 90°C, after the paraffin melts, ultrasonicate for 2 hours, then add sulfuric acid dropwise to it, adjust the pH of the system to 2~3, and form 30 after cooling. ~50nm graphene oxide-wrapped nanocapsules of phase change materials (referred to as phase change capsules).

[0039]Add porous graphene to the aqueous solution of nano phase change capsules according to the weight ratio of phase change capsules / porous graphene of 800 / 1, ultrasonicate for 6 hours, centrifuge the above solution, and take the precipitate and place it in a low temperature box at -20°C Freeze-drying to obtain a fluffy phase-change composite material with high specific surface area, high electrical conductivity and high thermal conductivity, and then the porous graphene-based phase-change composite material: positive / negative active material: binder weight ratio is 6:92:2 to prepare a solid content 60% positive / negative electrode sl...

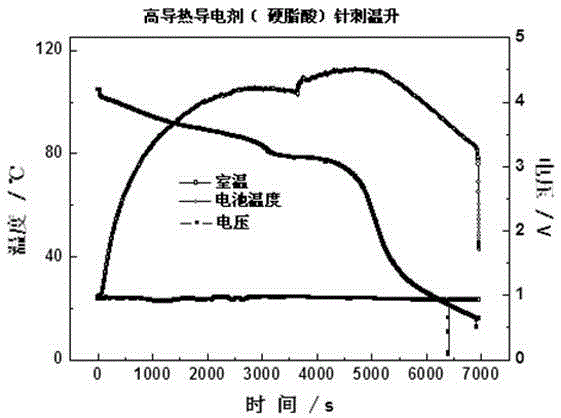

Embodiment 2

[0044] Add 300g of stearic acid into 1L of 0.5g / l graphene oxide solution, heat at 75°C, after the stearic acid melts, ultrasonicate for 1h, then add sulfuric acid dropwise to adjust the pH of the system to 2~3, After cooling, a 30-70nm graphene oxide-wrapped nanocapsule of phase-change material (referred to as phase-change capsule) is formed.

[0045] Add porous graphene to the aqueous solution of nano phase change capsules according to the weight ratio of phase change capsules / porous graphene of 800 / 1, ultrasonicate for 6 hours, centrifuge the above solution, and take the precipitate and place it in a low temperature box at -20°C Freeze-dry to obtain a fluffy high specific surface, high electrical conductivity and high thermal conductivity phase change composite material, and then prepare a solid content according to the porous graphene-based phase change composite material: positive / negative active material: binder weight ratio of 5:92:3 60% positive / negative electrode slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com