A preparation method of high thermal conductivity and high conductivity CNT interface modified ceramic matrix composite material

A composite material and high-conductivity technology, which is applied in the field of improving the thermal conductivity and electrical conductivity of ceramic matrix composite materials, and in the field of composite materials, can solve the problems of expensive CVD process equipment, poor dispersion, and long time, so as to achieve a stable and controllable process, which is beneficial to Industrialized production, the effect of improving the uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

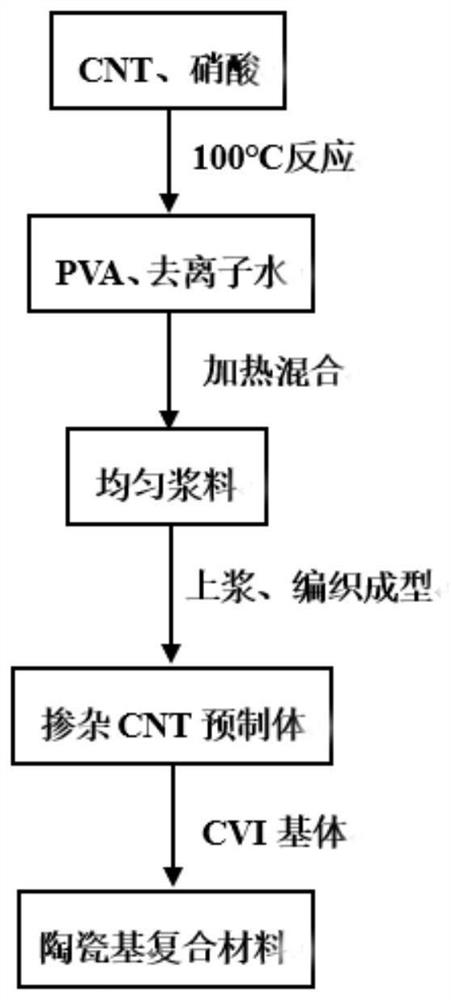

[0046] Step 1. Prepare CNT-nitric acid suspension with CNT and nitric acid at a mass ratio of 1:100, react at 100°C for 1 hour, let the suspension stand for 8 hours, filter off excess nitric acid, place CNT in a dialysis bag, and dialyze After 36 hours until the pH value of the dialysate was neutral, the CNTs were freeze-dried for 12 hours to obtain CNT powder.

[0047] Step 2. Preparation of CNT slurry: Pretreated CNT powder, polyvinyl alcohol, and deionized water in a mass ratio of 4:1:500 were boiled at 90°C for 40 minutes, ultrasonically dispersed to obtain CNT slurry, and the ultrasonic time was 20 minutes .

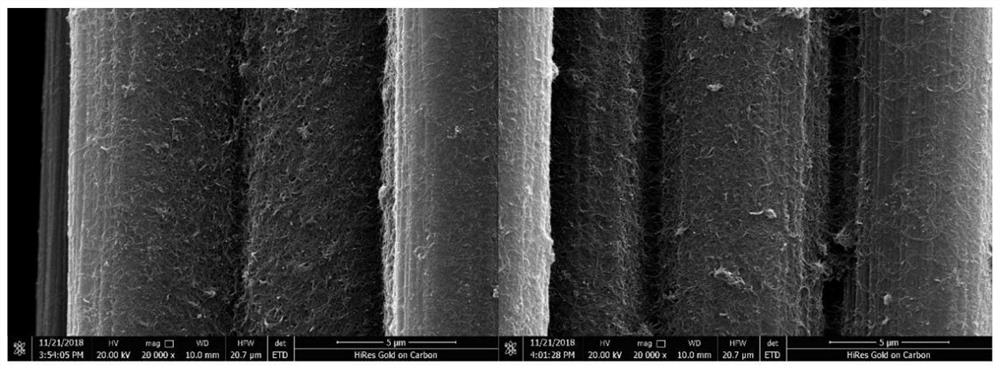

[0048] Step 3. Fiber sizing: set the sizing machine parameters such as the temperature of the sizing tank to 50°C, the drying temperature to 80°C, and the yarn speed to 20m / min, and use the fiber sizing process to evenly cover the fiber surface with CNT.

[0049] Step 4. Preparation of fiber prefabricated body: use plain weave fiber cloth, wherein the warp density ...

Embodiment 2

[0053] Step 1. CNT pre-oxidation treatment: prepare CNT-nitric acid suspension with CNT and nitric acid at a mass ratio of 1:100, react at 100°C for 1 hour, let the suspension stand for 10 hours, filter off excess nitric acid, and dialyze CNT The bag was dialyzed for 48 hours until the pH value of the dialysate was neutral, and the CNT was freeze-dried for 12 hours to obtain CNT powder.

[0054] Step 2. Preparation of CNT slurry: Pretreated CNT powder, polyvinyl alcohol, and deionized water in a mass ratio of 4:1:500 were boiled at 95°C for 45 minutes, and ultrasonically dispersed to obtain CNT slurry. The ultrasonic time was 25min.

[0055] Step 3. Fiber sizing: set the sizing machine parameters such as sizing tank temperature to 60°C, drying temperature to 90°C, yarn running speed to 30m / min, and use the fiber sizing process to evenly cover the fiber surface with CNT.

[0056] Step 4. Preparing the fiber prefabricated body: using plain weave fiber cloth, wherein the warp an...

Embodiment 3

[0060] Step 1. Prepare CNT-nitric acid suspension with CNT and nitric acid at a mass ratio of 1:135, react at 100°C for 1 hour, let the suspension stand for 8-12 hours, filter off excess nitric acid, and place CNT in a dialysis bag. Dialyze for 36-48 hours until the pH value of the dialysate is neutral, and freeze-dry the CNTs for 12 hours to obtain CNT powder.

[0061] Step 2. Cook the pretreated CNT powder, polyvinyl alcohol, and deionized water at a mass ratio of 4:1:500 at 90-100°C for 50 minutes, and ultrasonically disperse to obtain a CNT slurry. The ultrasonic time is 30 minutes.

[0062] Step 3. Set the sizing machine parameters such as the temperature of the sizing tank to 65°C, the drying temperature to 95°C, and the yarn running speed to 35m / min, and use the fiber sizing process to evenly cover the fiber surface with CNT.

[0063] Step 4. Weave the fiber cloth with a satin weave, wherein the warp and weft density are controlled to be 95 bundles / 10cm. The fiber clot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com