Chlorine and sulfur containing tail gas processing device and tail gas processing method thereof

A technology for tail gas treatment and tail gas, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

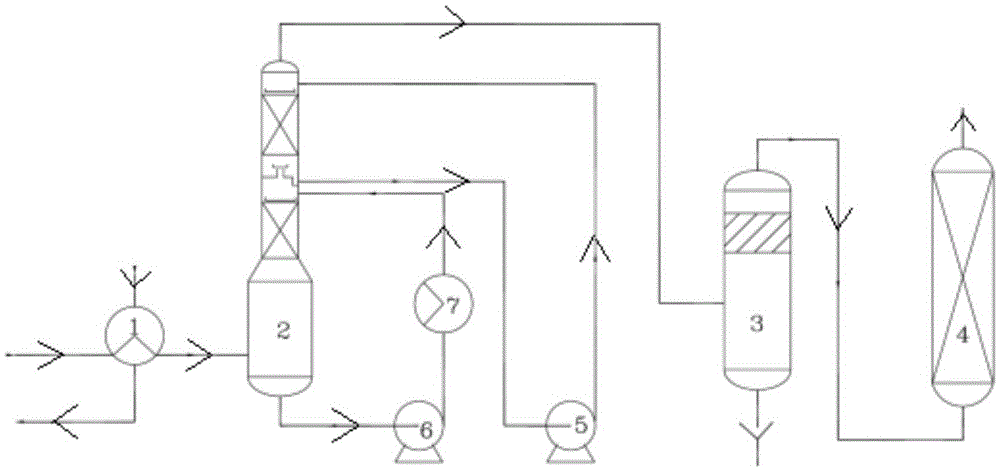

[0059] use as figure 1 A chlorine-containing and sulfur-containing tail gas treatment device is shown for tail gas treatment. The chlorine-containing and sulfur-containing tail gas is the exhaust gas produced after the catalyst is continuously regenerated and burnt in a propane or butane dehydrogenation device, and the hydrogen chloride content is 0.3vol%. , the sulfur dioxide content is 0.026vol%, and the chlorine content is 0.05vol%. The chlorine-containing and sulfur-containing tail gas enters the absorption tower 2 after heat exchange, and is countercurrently contacted with the lye (the mass fraction is 10% NaOH aqueous solution) sprayed on the top of the tower, and the tail gas The acid gas in the acid gas reacts with lye to form salt, which drops to the bottom of the tower and is sent to the top of the tower for circulation through the circulating water pump 5; the lye at the bottom of the tower is sent to the middle of the tower for circulation through the circulating ly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com