Cooling room for internal combustion locomotive

A technology for diesel locomotives and cooling chambers, applied in locomotives and other directions, can solve problems such as built-in design that is difficult to observe and maintain, product design needs to lag behind, and prolong production cycle, so as to improve indoor maintenance conditions, rational cooling chamber structure, and shorten production. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

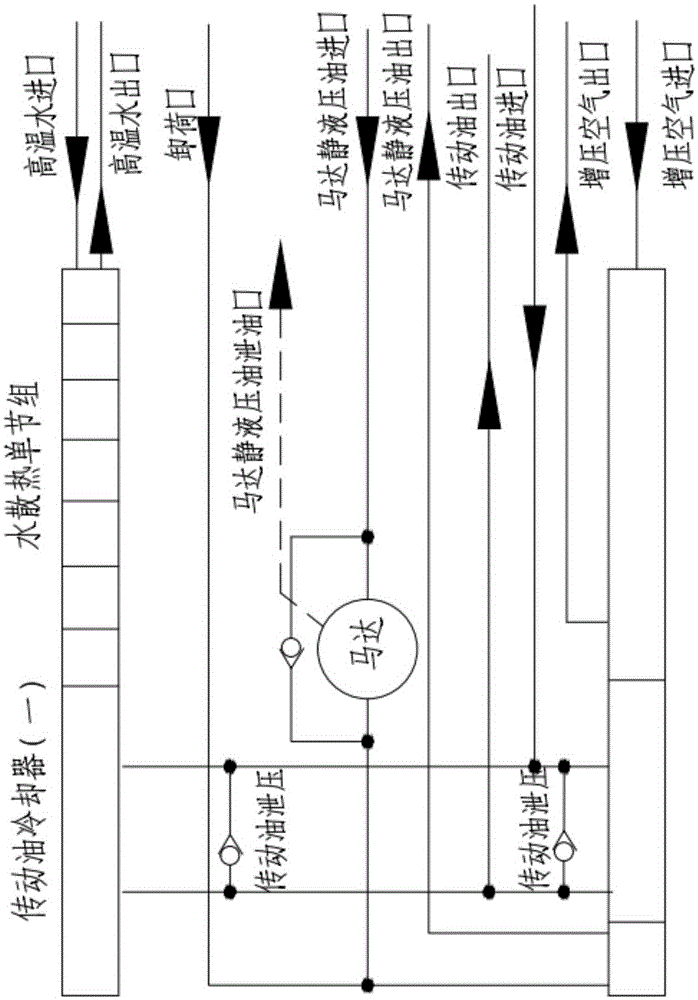

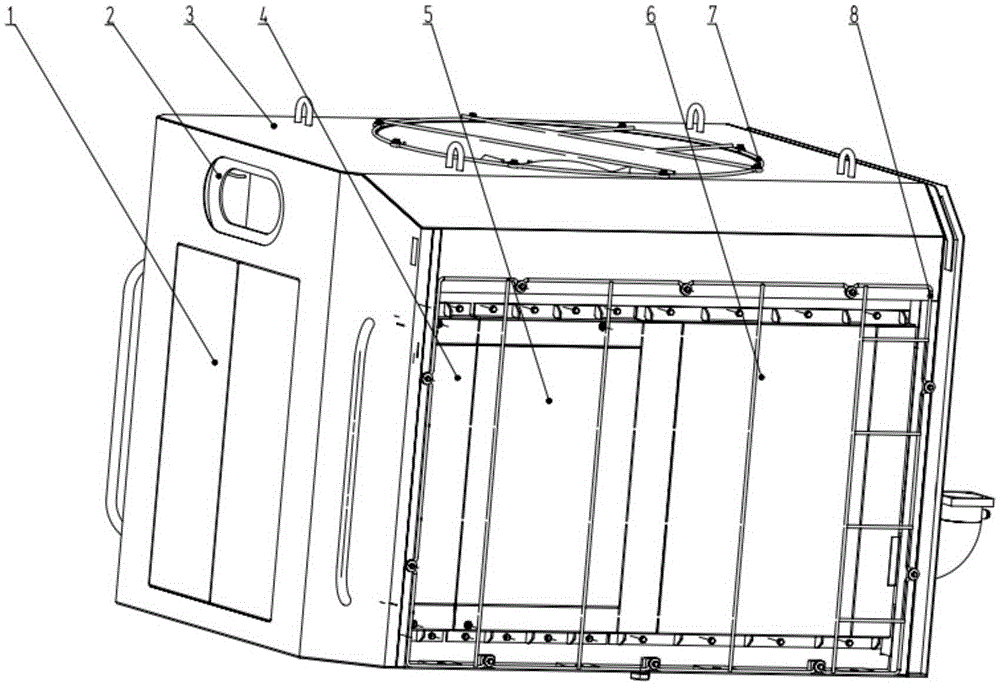

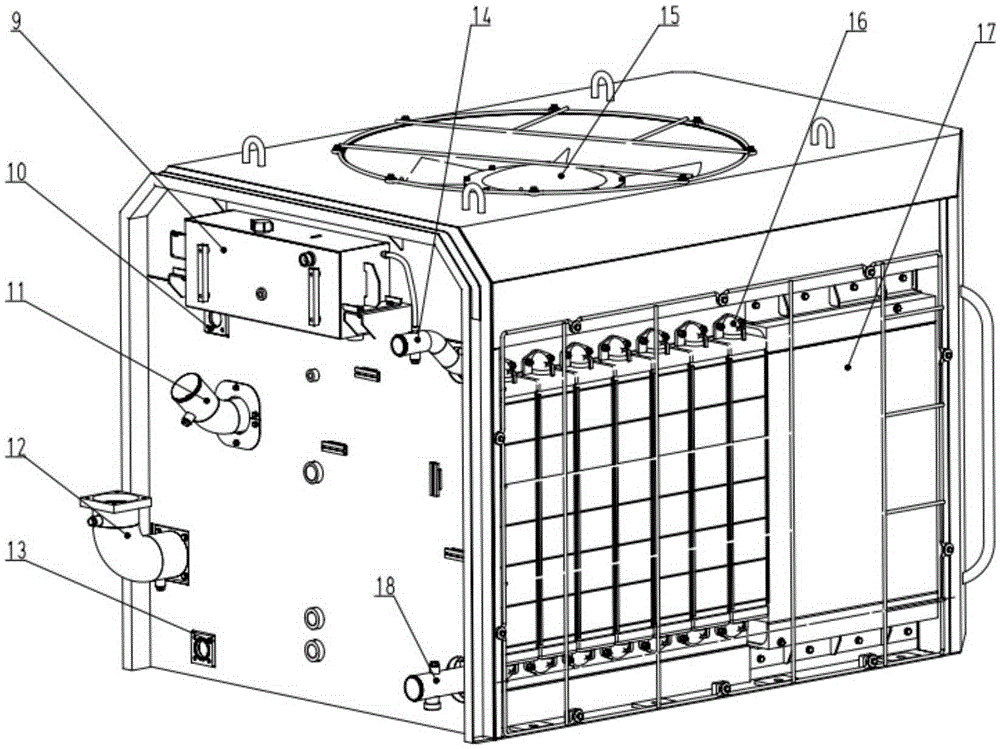

[0019] The invention unifies the cooling systems of the diesel locomotive into independent cooling chambers, which are directly installed on the chassis of the locomotive, so that the design of the cooling chamber can be carried out in parallel with the design of the car body, greatly reducing the interface data and shortening the production cycle. The engine water cooling system, charge air cooling system, transmission oil cooling system, hydraulic oil cooling system, cooling fan drive system, lighting system, expansion water tank 9, and hydrostatic oil tank are integrated in one cooling chamber. All cooling system components are integrated in a separate cooling chamber by means of a steel structure frame 3 . The cooling chamber is mounted directly on the locomotive chassis as a module of the diesel locomotive

[0020] The engine cooling water system mainly includes components such as a water cooling single-section group, an expansion tank 9, a collecting pipe, and water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com