Calibration blackbody light source and preparation method thereof

A black body light source and calibration technology, applied in the infrared field, can solve the problems of high heating power consumption, large volume, heavy weight, slow heat dissipation, etc., and achieve the effects of fast cooling speed, easy integration, and small thermal mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Please refer to Figure 1~Figure 7 Shown is the preparation method of the calibration black body light source of the present invention, comprises the following steps:

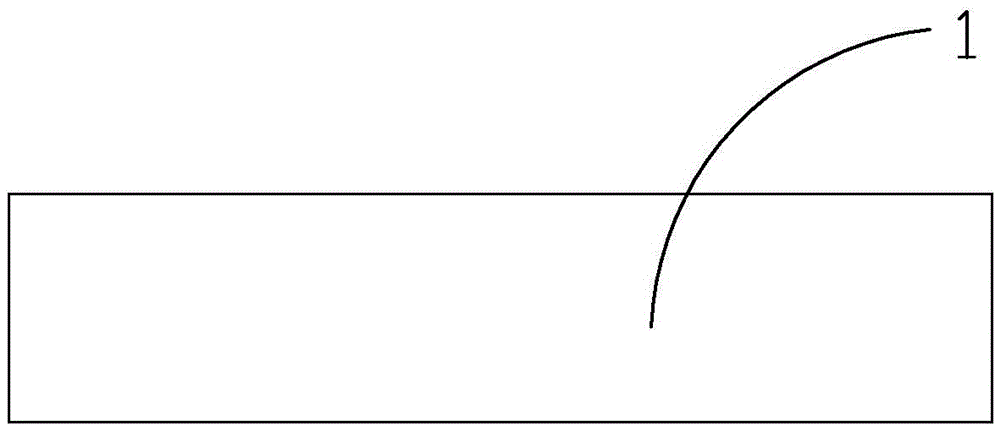

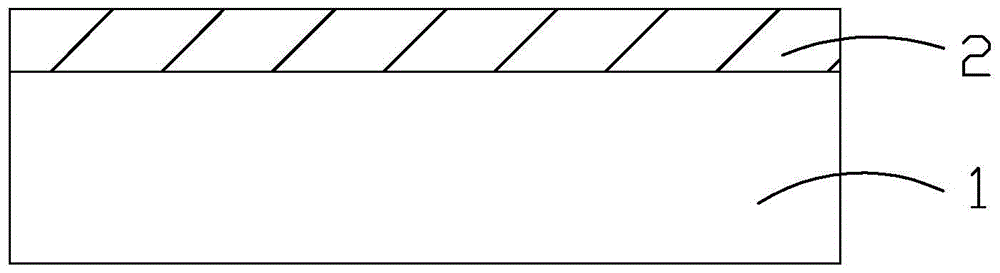

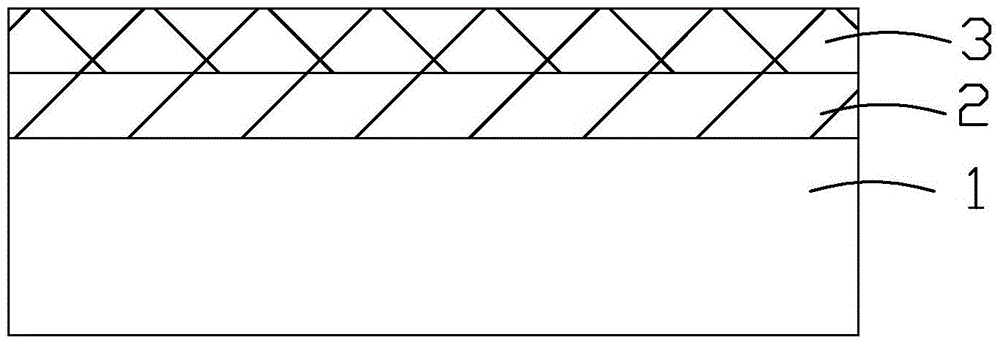

[0031] Provide a sheet-shaped substrate 1 with uniform thickness, and make a first insulating layer 2 with a certain thickness on the surface of the substrate 1; make a heating source on the surface of the first insulating layer 2 facing away from the substrate 1 3. The heating source 3 has a lead area 31 that can be electrically connected to an external circuit; a second insulating layer 4 of a certain thickness is fabricated on the surface of the heating source 3 facing away from the first insulating layer 2; Fabricate a temperature sensor 5 on the surface of the first in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com