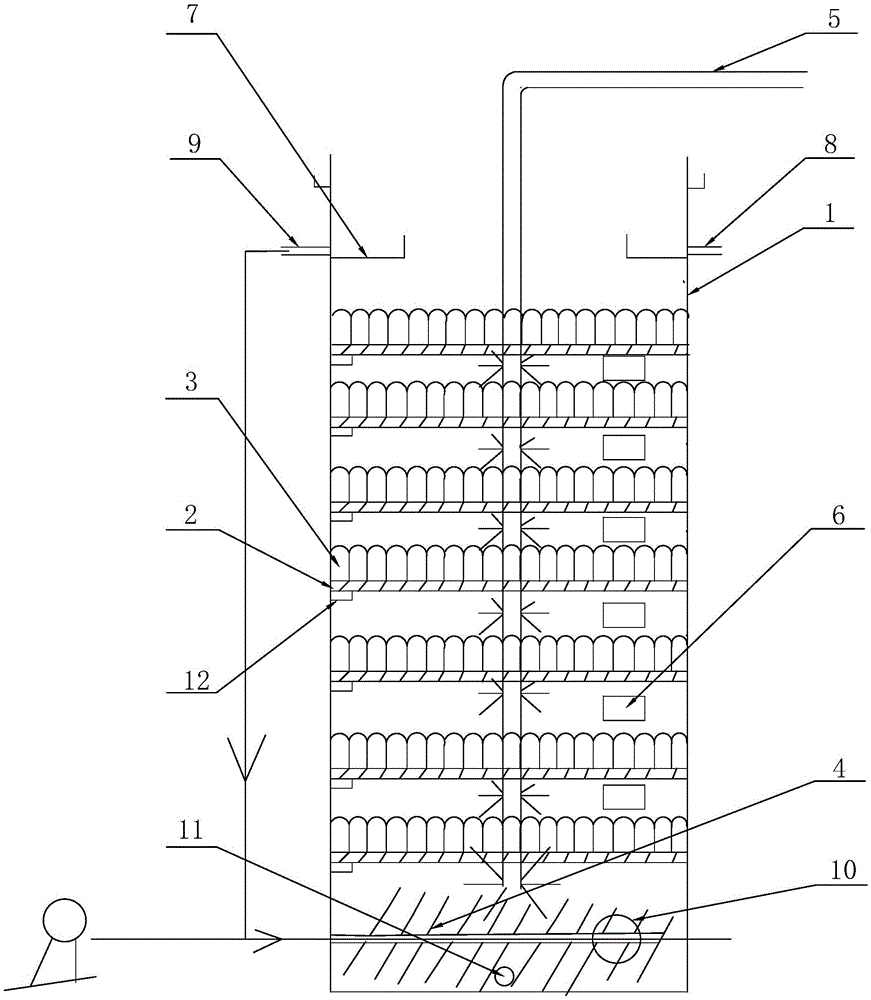

Efficient bin type micro-electrolysis generator and waste water treatment process thereof

A micro-electrolysis and generator technology, applied in water/sewage treatment, water/sewage treatment equipment, water treatment with fluid flow conditions, etc. Reaction effect, increase mass transfer effect, shorten reaction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

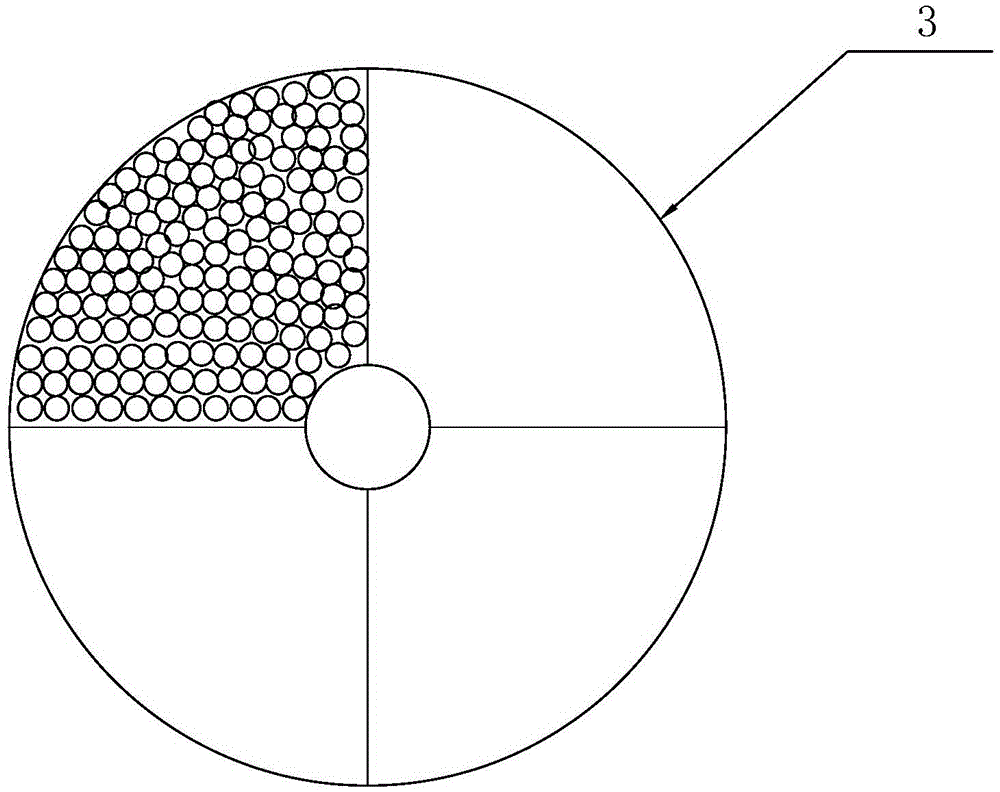

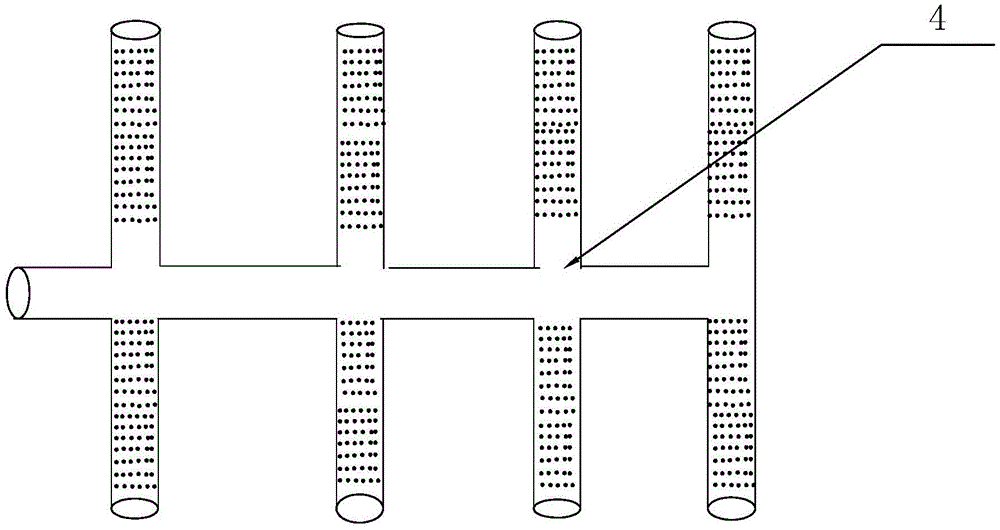

Method used

Image

Examples

Embodiment 1

[0048] Utilize the device of the present invention to treat the waste liquid of neutral measures in the oil field, and carry out micro-electrolysis treatment under the condition that the raw water quality COD is 1032mg / L and the viscosity is 10.98mPa. , 25, and 30 minutes, the COD of the water samples after the reaction was 774, 722, 681, 660, 640, and 619mg / L, and the COD removal rates were 25.00%, 30.04%, 34.01%, 36.05%, 37.98%, and 40.02%. ; Viscosities are 6.683, 3.23, 2.80, 2.77, 2.61, 2.59mPa.S respectively, comprehensively considered, the electrolysis time is 10-20min is more appropriate.

Embodiment 2

[0050] Utilize the device of the present invention to treat waste liquid from neutral measures in oil fields, and carry out micro-electrolysis treatment when the COD of the raw water quality is 1032 mg / L, and control the micro-electrolysis influent pH to be 1, 2, 3, 4, 5, 6, 7, respectively. 8. After the reaction, the COD of the water samples were 547, 526, 537, 566, 572, 578, 630, 676 mg / L, and the COD removal rates were 47.0%, 49.0%, 48.0%, 45.2%, 44.6%, 44.0 %, 39.0%, 34.5%, considering the corrosion of acid to the device and the difficulty of adjusting the pH, etc., the electrolysis pH is 5-6 is more suitable.

Embodiment 3

[0052] Utilize the device of the present invention to treat pharmaceutical factory waste water, and carry out micro-electrolysis treatment under the condition that raw water quality COD is 1522mg / L, respectively control the micro-electrolysis time to be 0, 5, 10, 15, 20, 25, 30min, and the water sample after the reaction is finished The COD is 774, 722, 681, 660, 640, 619mg / L, the COD removal rate is 35.0%, 38.2%, 42.8%, 46.5%, 50.6%, 54.3%, and the electrolysis time is 10-20min is more suitable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com