Method for reducing content of diastereoisomer impurity in Ledipasvir intermediate

A technology of diastereoisomers and enantiomers, applied in the field of diastereoisomer impurity content, to achieve the effects of reducing production costs, mild methods, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 formula (I) compound crude product

[0044] Route 1:

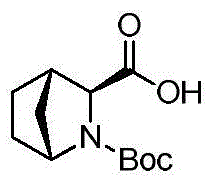

[0045] Taking methyl ester compound (SM) as initial raw material, concrete route is as follows:

[0046]

[0047] Take starting materials SM (500g), methanol (2.5kg) and Pd / C (5% w / w, 100g), replace with nitrogen, fill with hydrogen to 0.8-1.0MPa, react with 45-55°C for 20 hours, concentrate, Add 1Kg methanol and 2Kg water, adjust the pH to 8 with sodium carbonate, keep the temperature below 5°C, slowly add di-tert-butyl dicarbonate (90g) dropwise, stir and react for 2 hours, then naturally rise to room temperature, add DCM (dichloro methane) extraction, the organic phase was collected and concentrated to obtain 300 g of the crude product of compound 3.

[0048] The crude compound 3 (300g), water (1.5Kg), LiOH (50g) and tetrahydrofuran (1.5L) were added into a 5L three-necked flask, and reacted at 50°C for 24 hours, and the reaction solution was washed with 1L of dichloromethane,...

Embodiment 2

[0054] The purification of embodiment 2 formula (I) compound

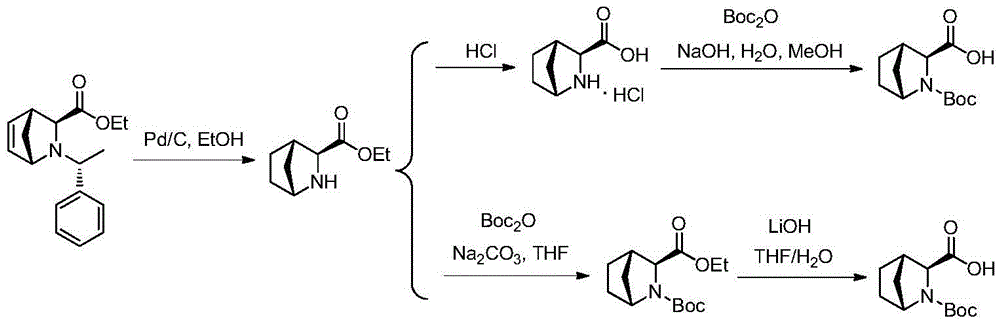

[0055] The specific route is as follows:

[0056]

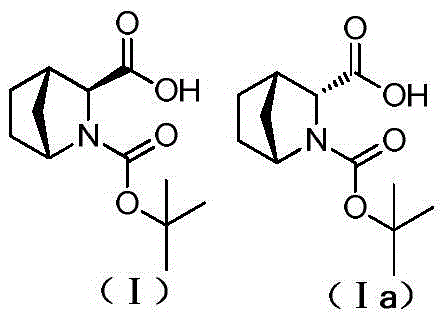

[0057] The crude product (10 g) of the compound of formula (I) obtained in Example 2 was dissolved in 30 mL of ethanol, the temperature was raised to 80 ° C, (R)-(+)-1-phenylethylamine (5.2 g) was added and stirred evenly, React for 2 hours, cool down to 20°C, filter with suction, dissolve the obtained filter cake in 100 mL of 0.5N hydrochloric acid solution at 0°C, adjust pH=1-1.5, add an equal volume of dichloromethane for extraction, take the organic phase, concentrate, and store at 20°C Crystallization and filtration gave 8.1 g of white solid with a yield of 81%, a de value of 99.8%, and a diastereomer impurity (Ia) content of 0.1%; mass spectrum: MS (M-H+): m / z 240.3 . 1 HNMR (400MHz, DMSO-d6): δ12.47(s, 1H), 4.12-4.05(d, 1H), 3.60(s, H), 2.58(s, 1H), 1.73-1.38(m, 5H), 1.31(s, 4H), 1.25(s, 3H), 1.23-1.20(t, 1H).

[0058] The diastereomer impurity (Ia) ...

Embodiment 4

[0059] Embodiment 4: the preparation of the pure product of formula (I) compound

[0060] The crude product (10 g) of the compound of formula (I) obtained in Example 1 was dissolved in 80 mL of ethyl acetate, the temperature was raised to 70 ° C, and (R)-(+)-1-phenylethylamine (7.5 g) was added and stirred Evenly, react for 2 hours, cool down to 40°C, filter with suction, and dissolve the obtained filter cake in 150mL of 0.1N sulfuric acid solution at 0°C, adjust pH=1-1.5, add 100mL of 1,2-dichloroethane to the water phase, Extract, take the organic phase, concentrate, crystallize at 0°C, and filter to obtain 8.5 g of white solid with a yield of 85%, a de value of 99.8%, and a diastereomeric impurity (Ia) content of 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com