Novel high-molecular-block dispersing agent, preparation method and application thereof

A technology of polymer and dispersant, applied in the field of new polymer block dispersant and its preparation, can solve the problems of insufficient anchoring ability and poor steric hindrance effect of dispersant, and achieve high controllability, strong adsorption strength, Strong and stable dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

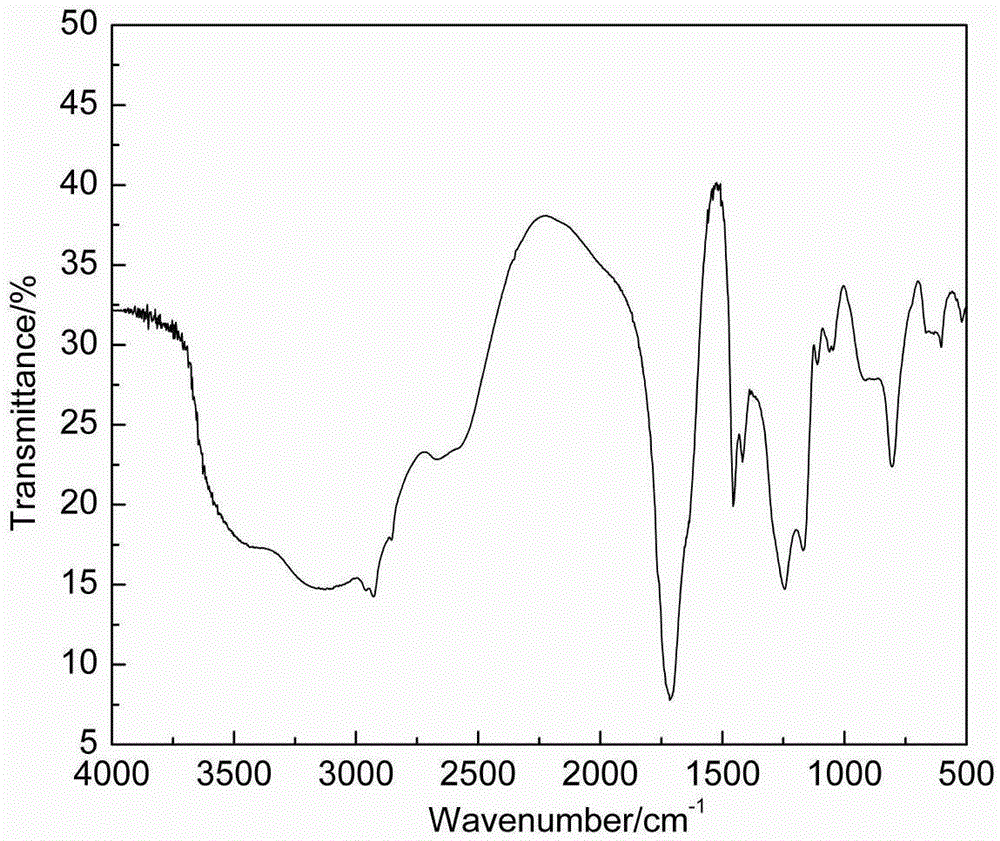

Image

Examples

preparation example Construction

[0034] The preparation method of a kind of novel polymer block dispersant provided by the invention comprises the following steps:

[0035]Step S1: Polymerize the monomer methacrylic acid, sodium styrene sulfonate, and N-isopropylacrylamide under the action of an initiator and a chain transfer agent to form a macromolecular chain transfer agent M-CTA, specifically, under nitrogen protection Next, the monomer methacrylic acid, sodium styrene sulfonate, and N-isopropylacrylamide were mixed evenly and added dropwise to a 250ml four-neck flask containing initiator, chain transfer agent and solvent, and the macromolecular chain was obtained after purification. Transfer agent M-CTA, in which the reaction temperature is 60-70°C, the monomer methacrylic acid, sodium styrene sulfonate, and N-isopropylacrylamide are mixed evenly, and the dropping time is 3-4 hours, and the temperature is kept for 3-5 hours , the solvent is at least one of N'N-dimethylformamide, dioxane, and tetrahydrofu...

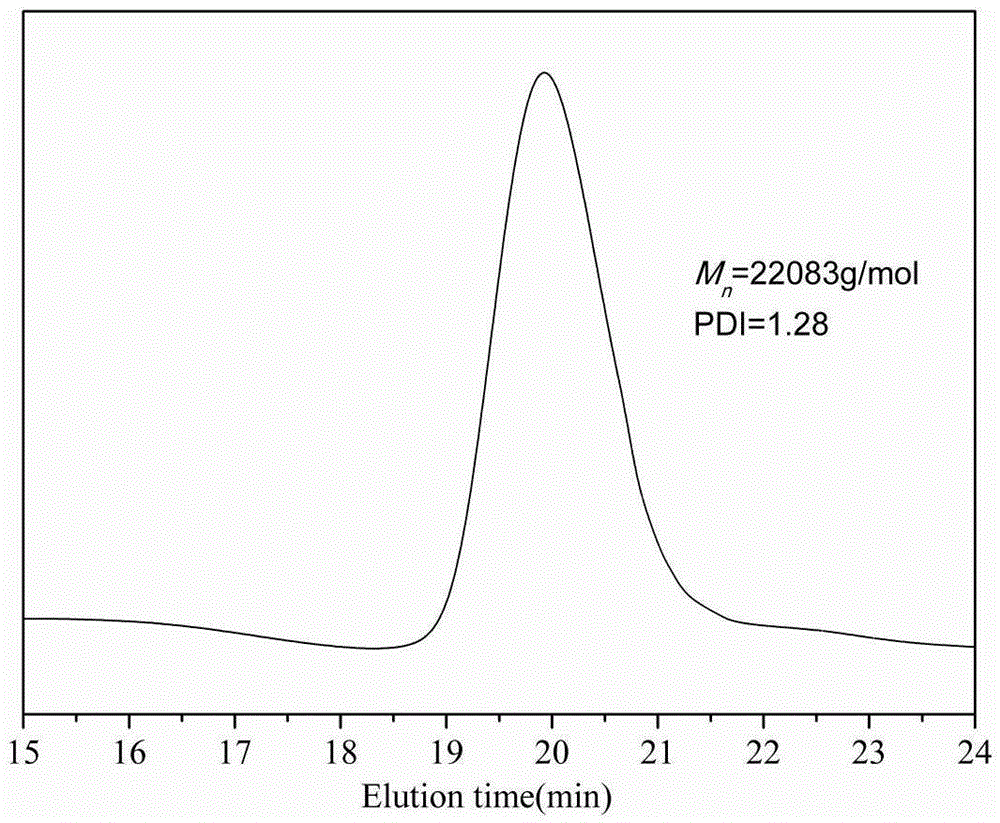

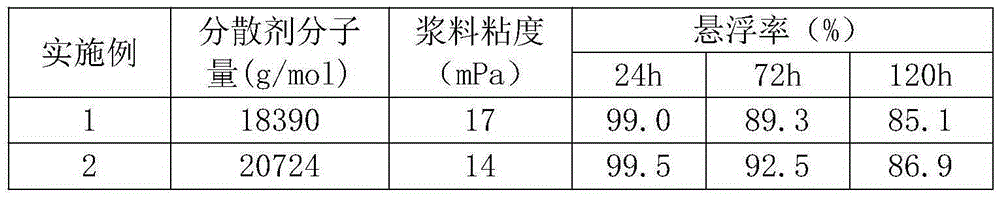

Embodiment 1

[0040] (1) Add 20ml solvent THF, 0.033gAIBN (2×10 -4 mol), 0.282g chain transfer agent BDATC (0.001mol), nitrogen gas flow, the reaction device was sealed, and the temperature was raised to 65°C.

[0041] (2) Mix 21.52g of MAA (0.25mol), 51.55g of SMAS (0.25mol), 28.3g of NIPAM (0.25mol) and 80ml of THF and add it dropwise to a four-necked flask for 3 hours. After the addition is complete, keep it at 65°C for 3 hours, and the reaction is over. Add distilled water dropwise to quench the free radicals, then vacuumize to remove the solvent to obtain the macromolecular chain transfer agent M-CTA.

[0042] (3) Add 50ml of DMF, 2.5g of M-CTA (0.001mol) and 0.033g of AIBN (2×10 -4 mol), nitrogen gas, after heating up to 70°C, start to drop a mixed solution of 25g APEG (molecular weight: 500g / mol) (0.05mol), 6.5g HEMA (0.05mol) and 50mlDMF, and the dropping time is 5h. After 12 hours of reaction until the end of the reaction, it was cooled to room temperature.

[0043] (4) The solv...

Embodiment 2

[0045] (1) Add 30ml solvent THF, 0.033gAIBN (2×10 -4 mol), 0.282g chain transfer agent BDATC (0.001mol), nitrogen gas flow, the reaction device was sealed, and the temperature was raised to 70°C.

[0046] (2) Mix 17.21g of MAA (0.2mol), 41.24g of SMAS (0.2mol), 16.97g of NIPAM (0.15mol) and 70ml of THF and add it dropwise to a four-necked flask for 3 hours. After the addition is completed, keep it at 70°C for 3 hours, and the reaction is over. Add distilled water dropwise to quench the free radicals, then vacuumize to remove the solvent to obtain the macromolecular chain transfer agent M-CTA.

[0047] (3) Add 55ml of DMF, 4.7g of M-CTA (0.001mol) and 0.033g of AIBN (2×10 -4 mol), nitrogen gas, after heating up to 70°C, start to drop the mixed solution of 70g APEG (molecular weight 700g / mol) (0.1mol), 6.5g HEMA (0.05mol) and 50mlDMF, the dropping time is 5h, and then maintain after the dropping is completed After 12 hours of reaction until the end of the reaction, it was cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com