A comprehensive treatment method for acrylate production wastewater

A technology for acrylate and waste water production, which is applied in natural water treatment, water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of wide molecular weight distribution, large dispersion, and poor effect, and achieve uniformity improvement, Good stability, reduce the effect of processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

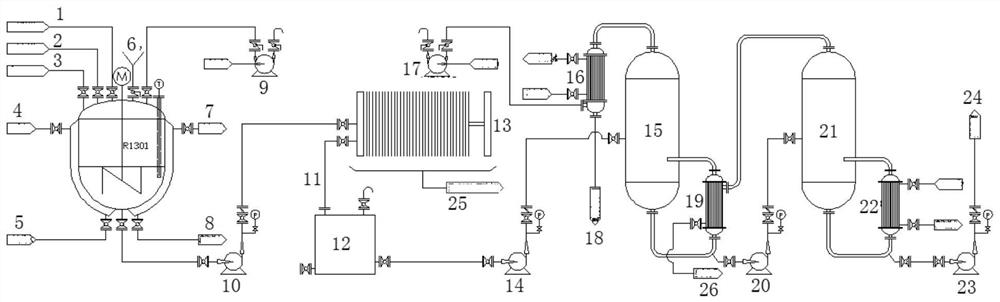

Image

Examples

Embodiment 1

[0039] Take 600g of acrylate production wastewater with a solid content of 15.5% (in which sodium acrylate accounts for about 12-13%), adjust the pH to 6 with sodium hydroxide, add 60g of chain transfer agent isopropanol to the mixed wastewater, and stir at room temperature After dissolving, add initiator benzoyl peroxide 6g, sodium bisulfite 12g, heat up to 80°C; keep warm for 4 hours to carry out polymerization reaction, after the reaction waste water is cooled to room temperature, then pass through nanofiltration and ultrafiltration membrane separation module Separating water and small molecular salts to obtain poly(meth)acrylate sodium aqueous solution, solid night separation; the molecular weight of the produced sodium polyacrylate is 4600, the dispersion Mw / Mn=1.25, and the purity is greater than 90%; after separation, it contains a small amount of Other waste water of sodium acrylate is heated and concentrated, fractionated isopropanol is cooled and reused during concent...

Embodiment 2

[0041] Take 600g of acrylate production wastewater with a solid content of 15.5% (wherein sodium acrylate accounts for about 12 to 13%), adjust the pH to 8 with sodium hydroxide, add 10g of chain transfer agent dodecanethiol to the mixed wastewater, and After stirring and dissolving, add initiator cumene hydroperoxide 6g, potassium bisulfite 12g, heat up to 50°C; keep warm for 9 hours to carry out polymerization reaction, after the reaction wastewater is cooled to room temperature, pass through nanofiltration and ultrafiltration membranes in turn The separation component separates water and small molecular salts to obtain an aqueous solution of sodium poly(meth)acrylate, which is separated overnight; the molecular weight of the produced sodium polyacrylate is 5510, the dispersion Mw / Mn=1.30, and the purity is greater than 90%. After separation, other wastewater containing a small amount of sodium acrylate is heated and concentrated, heavy components are incinerated, and light c...

Embodiment 3

[0043] Take 600g of acrylate production wastewater with a solid content of 15.5% (wherein sodium acrylate accounts for about 12-13%), adjust the pH to 6 with sodium carbonate, add 20g of chain transfer agent sodium phosphate to the mixed wastewater, stir and dissolve at room temperature Finally, add initiator sodium persulfate 6g, sodium bisulfite 6g, hydrogen peroxide 12g, heat up to 80°C; keep warm for 8 hours to carry out polymerization reaction, after the waste water after the reaction is cooled to room temperature, concentrate the solution under reduced pressure to 210ml about 1 / 3 volume, fractionated butanol is cooled and recycled during concentration, 100g ethanol is added, stirred for 0.5h, after standing for 15min, poly(meth)acrylate sodium filter cake is obtained after pressure filtration, and the molecular weight of filter cake gained sodium polyacrylate is in 3860, dispersion Mw / Mn=1.17, purity greater than 90%; fractionate the filtrate obtained by pressure filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com