Method and device for maintaining activity of electrolyte during process of acrylonitrile electrolysis for preparing adiponitrile

An electrolyte and adiponitrile technology, which is applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problem of reducing the continuous use time of acrylonitrile electrolytic cells, changing the electrolytic characteristics of acrylonitrile electrolytic cells, and reducing the yield of adiponitrile products. Problems such as efficiency and current efficiency can be achieved to prolong the continuous use time, improve product yield and current efficiency, and reduce the concentration of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

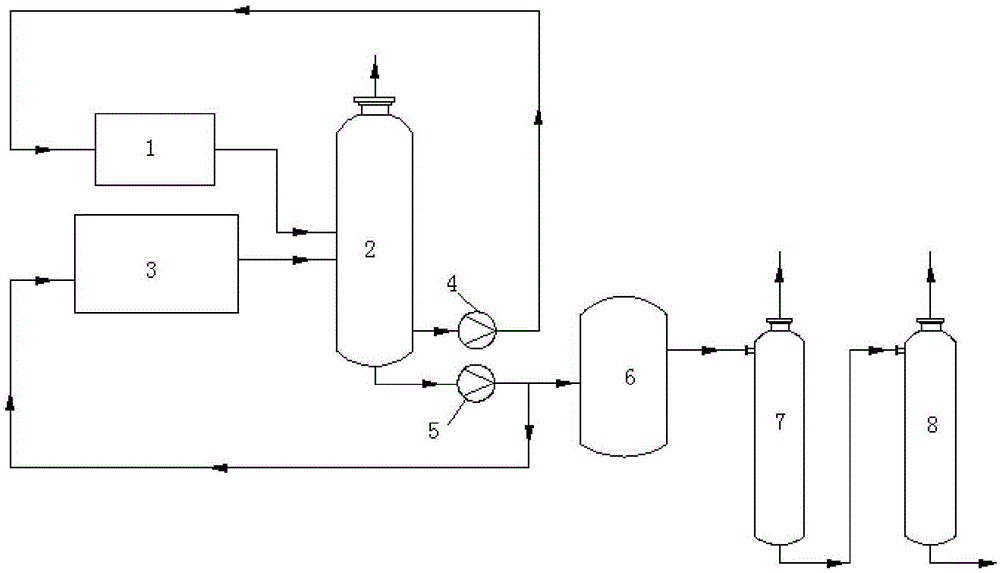

[0023] Such as figure 1 As shown, the device for maintaining the electrolyte activity in the process of preparing adiponitrile by electrolysis of acrylonitrile includes an iron-removing electrolytic cell 1 and an electrolyte pump 4. The feed port of the iron-removing electrolytic cell 1 is separated from gas and liquid by the electrolyte pump 4 The lower part of the device 2 is connected, and the discharge port of the iron removal electrolytic cell 1 is connected to the middle part of the gas-liquid separator 2; the iron removal electrolytic cell 1 is a monopolar electrolytic cell; the anode of the iron removal electrolytic cell 1 is titanium Base insoluble anode, cathode material is titanium.

[0024] The method for maintaining the electrolyte activity in the process of preparing adiponitrile by electrolysis of acrylonitrile includes the following steps:

[0025] (1) After the electrolyte flows into the gas-liquid separator 2 for gas-liquid separation, part of the electrolyte is ...

Embodiment 2

[0030] Such as figure 1 As shown, the device for maintaining the electrolyte activity in the process of preparing adiponitrile by electrolysis of acrylonitrile includes an iron-removing electrolytic cell 1 and an electrolyte pump 4. The feed port of the iron-removing electrolytic cell 1 is separated from gas and liquid by the electrolyte pump 4 The lower part of the device 2 is connected, and the discharge port of the iron removal electrolytic cell 1 is connected to the middle part of the gas-liquid separator 2; the iron removal electrolytic cell 1 is a monopolar electrolytic cell; the anode of the iron removal electrolytic cell 1 is titanium Base insoluble anode, cathode material is carbon steel.

[0031] The method for maintaining the electrolyte activity in the process of preparing adiponitrile by electrolysis of acrylonitrile includes the following steps:

[0032] (1) After the electrolyte flows into the gas-liquid separator 2 for gas-liquid separation, part of the electrolyte...

Embodiment 3

[0037] Such as figure 1 As shown, the device for maintaining the electrolyte activity in the process of preparing adiponitrile by electrolysis of acrylonitrile includes an iron-removing electrolytic cell 1 and an electrolyte pump 4. The feed port of the iron-removing electrolytic cell 1 is separated from gas and liquid by the electrolyte pump 4 The lower part of the device 2 is connected, and the discharge port of the iron removal electrolytic cell 1 is connected to the middle part of the gas-liquid separator 2; the iron removal electrolytic cell 1 is a bipolar electrolytic cell; the anode of the iron removal electrolytic cell 1 is platinum Base insoluble anode, cathode material is titanium.

[0038] The method for maintaining the electrolyte activity in the process of preparing adiponitrile by electrolysis of acrylonitrile includes the following steps:

[0039] (1) After the electrolyte flows into the gas-liquid separator 2 for gas-liquid separation, part of the electrolyte is di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap