Silk non-woven fabric applicable to baby wet wipes

A technology of silk non-woven fabrics and baby wipes, which is applied in the field of hygiene products to achieve the effects of increasing surface tension, comfort, excellent fast water absorption performance, and improving water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

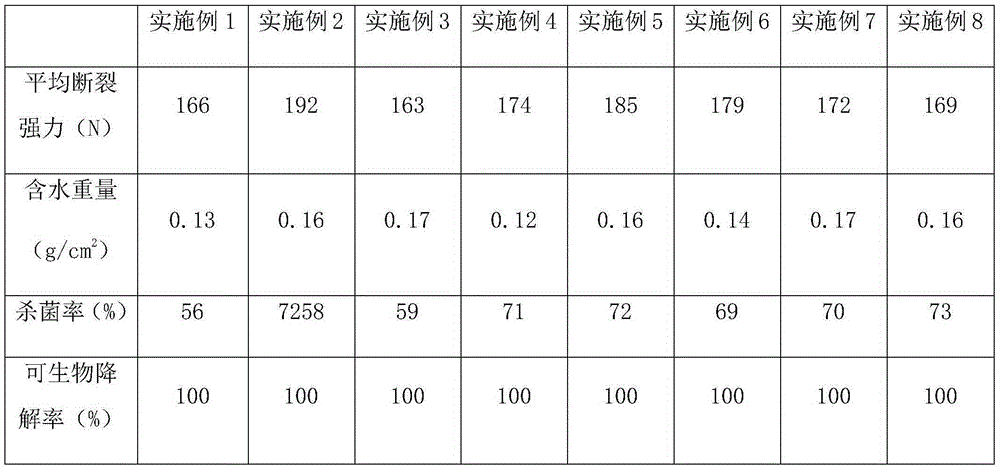

Examples

Embodiment 1

[0028] (1) Remove impurities from the leftovers of spun silk, after degumming and drying, place them in a low-temperature plasma instrument for low-temperature plasma treatment for 2 minutes, take them out and impregnate them in 10g / L fatty alcohol polyoxyethylene ether sodium sulfate surface active 15min, shake at constant temperature, take it out, remove excess liquid on the surface, put it into an oven to dry, and obtain the silk fiber of hydrophilic modification treatment, and the contact angle of the silk fiber of its hydrophilic modification treatment is 70 °.

[0029] (2) At first the silk fiber and the bamboo fiber distribution of the hydrophilic modification treatment that step (1) prepares is paved after carding and is 12g / cm 2 The silk fiber web and surface density is 35g / cm 2 The bamboo fiber net, and then put the silk fiber net on the upper layer of the bamboo fiber net, and the two are closely combined by spunlace cross-laying. The specific process parameters are...

Embodiment 2

[0032] (1) Remove impurities from the leftovers of silk, after degumming and drying, place in a low-temperature plasma instrument for low-temperature plasma treatment for 5 minutes, take it out and immerse it in a solution of 5g / L alkyl polyglucoside surfactant 30min, shake at a constant temperature, take it out, remove excess liquid on the surface, put it into an oven for drying, and obtain a hydrophilic modified silk fiber, and the contact angle of the hydrophilic modified silk fiber is 60°.

[0033] (2) At first the silk fiber and the bamboo fiber distribution of the hydrophilic modification treatment that step (1) prepares is paved after carding and is 14g / cm 2 The silk fiber web and surface density is 50g / cm 2 The bamboo fiber net, and then put the silk fiber net on the upper layer of the bamboo fiber net, and the two are closely combined by spunlace cross-laying. The specific process parameters are: the action distance of the water needle is 8mm, and the diameter of the ...

Embodiment 3

[0036] (1) Remove impurities from the scraps of spun silk, after degumming and drying, place them in a low-temperature plasma instrument for low-temperature plasma treatment for 3 minutes, take them out and impregnate them in 7g / L fatty alcohol polyoxyethylene ether sodium sulfate surface active 20min, shake at constant temperature, take it out, remove the excess liquid on the surface, put it into an oven for drying, and obtain the silk fiber of hydrophilic modification treatment, and the contact angle of the silk fiber of its hydrophilic modification treatment is 55 °.

[0037] (2) At first the silk fiber and the bamboo fiber distribution of the hydrophilic modification treatment that step (1) prepares is paved after carding and is 13g / cm 2 The silk fiber web and surface density is 45g / cm 2The bamboo fiber net, and then put the silk fiber net on the upper layer of the bamboo fiber net, and the two are closely combined by spunlace cross-laying. The specific process parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com