Semiconductor structure and method of forming same, method of processing semiconductor structure

A processing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, microstructure technology, etc., can solve problems such as easy formation of fragments, cost loss, scrapping of MEMS devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background art, thin wafers formed with MEMS thin films are prone to breakage during wet processing.

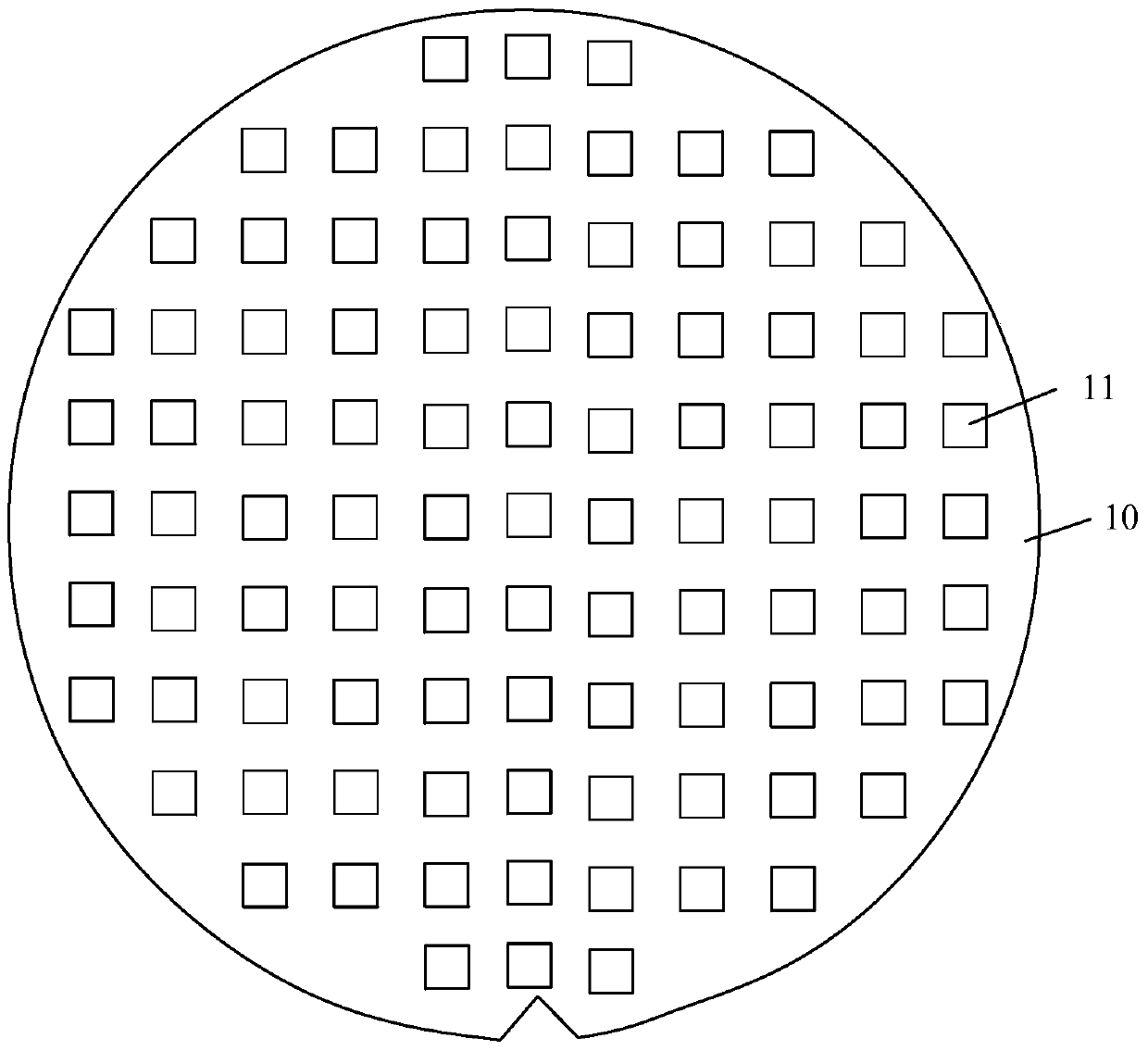

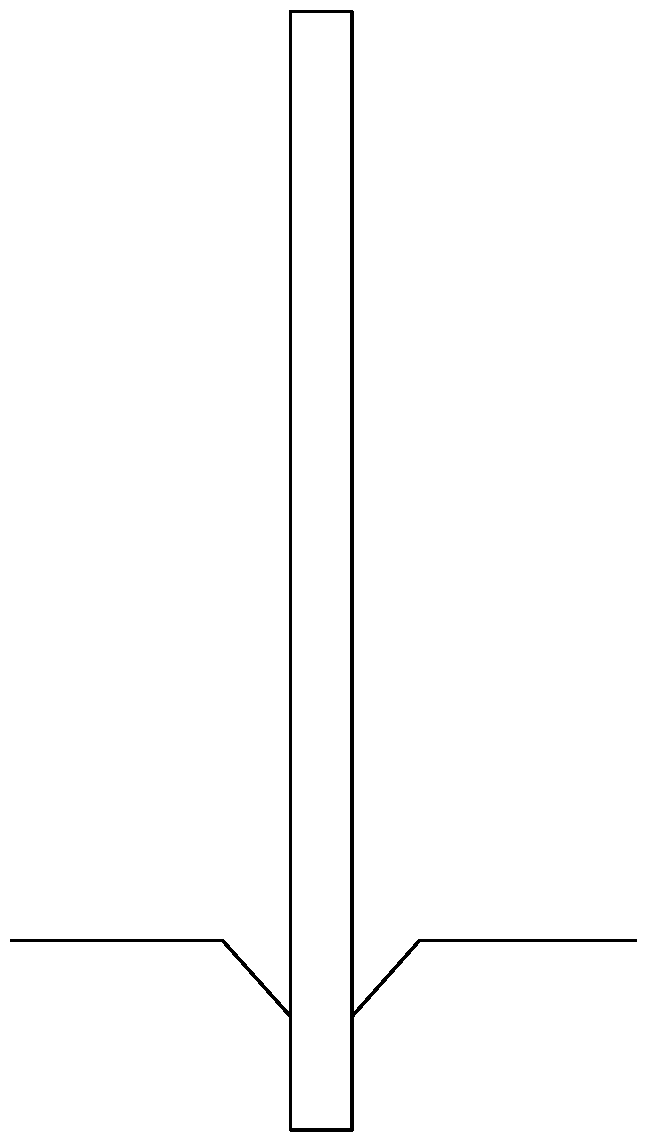

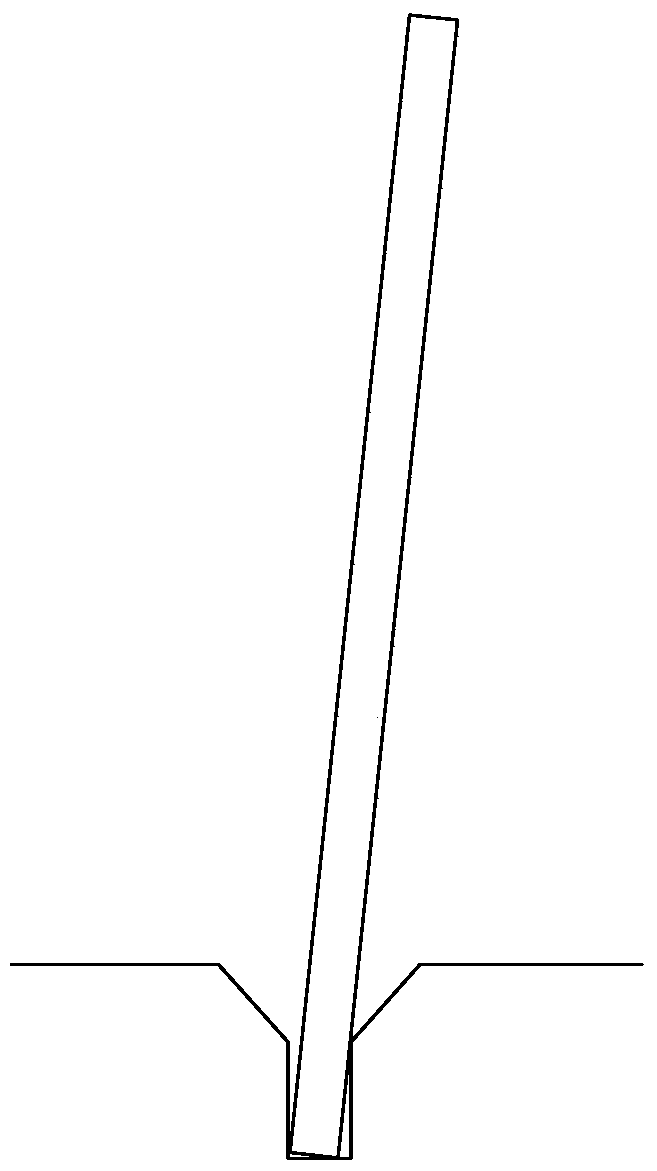

[0039] It was found that during wet processing, wafers are usually placed vertically on a wafer holder to facilitate simultaneous processing of multiple wafers. There are a plurality of guide grooves on the wafer guide frame, the thickness of the grooves is usually closer to the thickness of the wafer, and the wafer is vertically placed in the guide grooves, and the position is fixed (please refer to figure 2 ), able to maintain a vertical state. However, after thinning the wafer with the MEMS thin film, the thickness of the wafer drops a lot. When the subsequent wet process is performed, the thickness of the thinned wafer is quite different from the size of the groove, so that the wafer is in the wafer. The position on the round guide frame cannot be fixed, and it is easy to tilt (please refer to image 3 ), and when a wafer is tilted, it is eas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com