Acid-washing process for diode chip

A diode and secondary pickling technology, applied in the field of diodes, can solve the problems of secondary pollution, dissolution, and affecting product quality, and achieve the effect of reducing metal ions, improving electrical properties and high-temperature electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

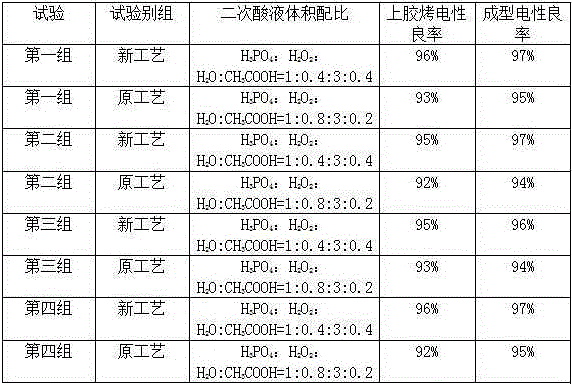

Examples

Embodiment 1

[0012] The pickling process of the diode chip in this embodiment, the specific steps of the pickling process are as follows:

[0013] (1) Pickling once: place the diode chip in HNO with a volume ratio of 9:9:12:4 3 , HF, CH 3 COOH and H 2 SO 4 Pickling in the mixed solution for 115s;

[0014] (2) Second pickling: The diode chip after the first pickling is re-used with H with a volume ratio of 1:0.4:3:0.4 3 PO 4 、H 2 o 2 、H 2 O and CH 3 Pickling with COOH mixed solution for 75s;

[0015] (3) Cleaning with hydrogen peroxide and ammonia water: use NH with a volume ratio of 2:1:5 for the diode chip after the second pickling 3 . h 2 O, H 2 O and H 2 o 2 Wash for 3 minutes;

[0016] (4) Ultrasonic cleaning with water: finally, ultrasonically clean the above-mentioned diode chip with water for 8 minutes.

Embodiment 2

[0018] The pickling process of the diode chip in this embodiment, the specific steps of the pickling process are as follows:

[0019] (1) Pickling once: place the diode chip in HNO with a volume ratio of 9:9:12:4 3 , HF, CH 3 COOH and H 2 SO 4 Pickling in the mixed solution for 125s;

[0020] (2) Second pickling: The diode chip after the first pickling is re-used with H with a volume ratio of 1:0.4:3:0.4 3 PO 4 、H 2 o 2 、H 2 O and CH 3 Pickling with COOH mixed solution for 73s;

[0021] (3) Cleaning with hydrogen peroxide and ammonia water: use NH with a volume ratio of 2:1:5 for the diode chip after the second pickling 3 . h 2 O, H 2 O and H 2 o 2 Wash for 2 minutes;

[0022] (4) Ultrasonic cleaning with water: Finally, ultrasonically clean the diode chip with water for 5 minutes.

Embodiment 3

[0024] The pickling process of the diode chip in this embodiment, the specific steps of the pickling process are as follows:

[0025] (1) Pickling once: place the diode chip in HNO with a volume ratio of 9:9:12:4 3 , HF, CH 3 COOH and H 2 SO 4 Pickling in the mixed solution for 120s;

[0026] (2) Second pickling: The diode chip after the first pickling is re-used with H with a volume ratio of 1:0.4:3:0.4 3 PO 4 、H 2 o 2 、H 2 O and CH 3 Pickling with COOH mixed solution for 74s;

[0027] (3) Cleaning with hydrogen peroxide and ammonia water: use NH with a volume ratio of 2:1:5 for the diode chip after the second pickling 3 . h 2 O, H 2 O and H 2 o 2 Wash for 2.5 minutes;

[0028] (4) Ultrasonic cleaning with water: finally, ultrasonically clean the above-mentioned diode chip with water for 6 minutes.

[0029] Secondary pickling solution H in embodiments 1 to 3 3 PO 4 、H 2 o 2 、H 2 O and CH 3 The configuration of the COOH mixture is: add water first, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com