Resist underlayer film forming composition containing polymer which contains nitrogen-containing ring compound

一种抗蚀剂下层、化合物的技术,应用在形成该防反射膜的组合物领域,能够解决活性光线驻波的影响大问题等问题,达到广焦点深度裕量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078]The weight-average molecular weight shown in the following synthesis examples is the result of measurement by gel permeation chromatography (hereinafter abbreviated as GPC). For the measurement, a GPC apparatus manufactured by Toray Co., Ltd. was used, and the measurement conditions and the like are as follows. In addition, the degree of dispersion shown in the following synthesis examples was calculated from the measured weight average molecular weight and number average molecular weight.

[0079] GPC column: Shodex [registered trademark] Asahipak [registered trademark] (manufactured by Showa Denko Co., Ltd.)

[0080] Column temperature: 40°C

[0081] Solvent: N,N-Dimethylformamide (DMF)

[0082] Flow rate: 0.6ml / min

[0083] Standard sample: standard polystyrene sample (manufactured by Toray Co., Ltd.)

[0084] Detector: RI detector (manufactured by Toray Corporation, RI-8020)

Synthetic example 1

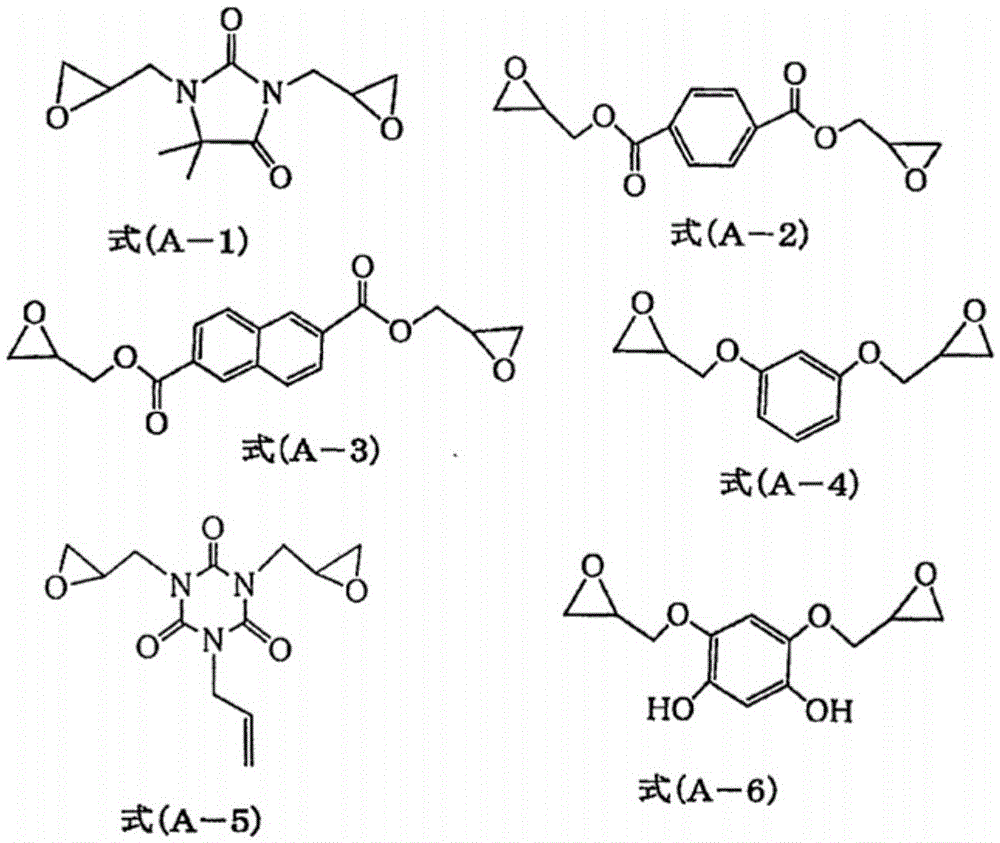

[0086] In a reaction vessel, 3 g of 1,3-diglycidyl-5,5-dimethylhydantoin, 0.71 g of resorcinol diglycidyl ether, 1.82 g of fumaric acid, ethyl triphenyl Bromination 0.29 g and 0.008 g of hydroquinone were added to 13.6 g of propylene glycol monomethyl ether and dissolved. After replacing the reaction vessel with nitrogen, the reaction was performed at 135° C. for 4 hours to obtain a polymer solution. The polymer solution did not become cloudy even when it was cooled to room temperature, and its solubility in propylene glycol monomethyl ether was good. As a result of GPC analysis, the obtained polymer corresponded to the formula (3-1), and the weight average molecular weight in terms of standard polystyrene was 6,730.

Synthetic example 2

[0088] In a reaction vessel, 3 g of 1,3-diglycidyl-5,5-dimethylhydantoin, 0.41 g of isophthalic acid, 1.16 g of fumaric acid, ethyl triphenyl bromide 0.23 g and 0.007 g of hydroquinone were added to 11.6 g of propylene glycol monomethyl ether and dissolved. After replacing the reaction vessel with nitrogen, the reaction was performed at 135° C. for 4 hours to obtain a polymer solution. The polymer solution did not become cloudy even when it was cooled to room temperature, and its solubility in propylene glycol monomethyl ether was good. As a result of GPC analysis, the obtained polymer corresponded to the formula (3-2), and the weight average molecular weight in terms of standard polystyrene was 8537.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com