Sludge dewatering, drying and incinerating system and method

A technology for sludge dewatering and sludge drying, which is applied in combustion methods, chemical instruments and methods, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving thermal energy utilization efficiency, high resource utilization efficiency, and significant resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

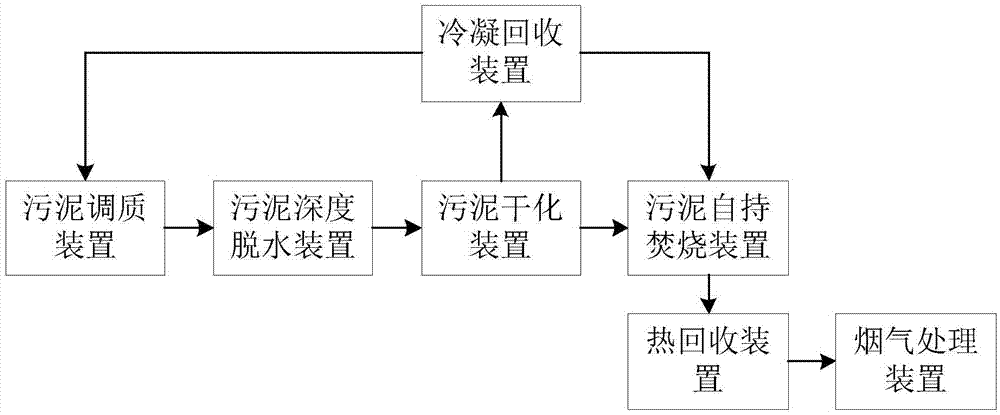

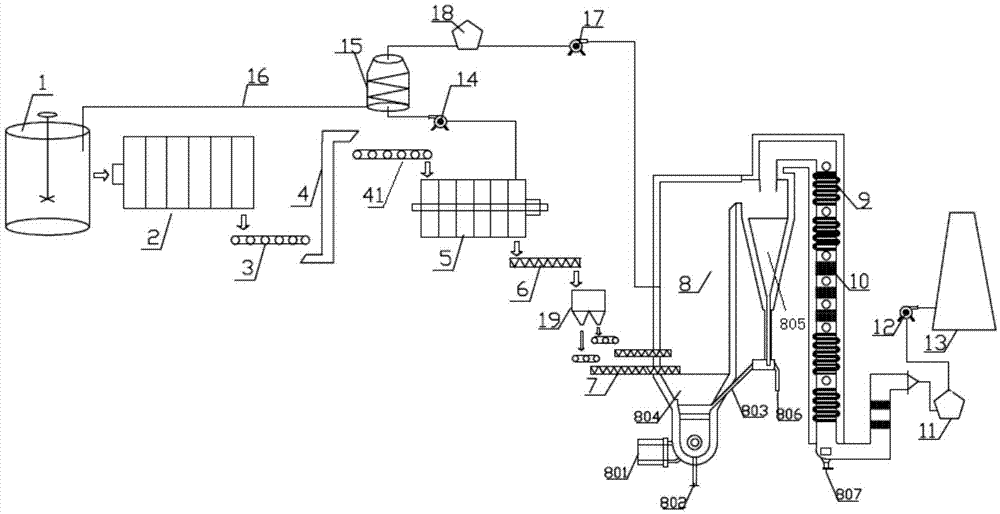

[0030] like figure 1 The sludge dehydration, drying and incineration system according to the present invention is shown, including a sludge conditioning device 1, a sludge deep dewatering device, a sludge drying device, a sludge self-sustaining incineration device, and a flue gas treatment device, which are connected in sequence. , the sludge is sequentially conditioned, dehydrated, dried and incinerated through the above-mentioned devices, and finally divided into residues and gas discharged up to the standard. The sludge drying device is connected with a condensation recovery device, and the condensation recovery device is respectively connected with the The sludge conditioning device 1 is connected with a sludge self-sustained incineration device, and a heat recovery device is also connected between the sludge self-sustained incineration device and the flue gas treatment device;

[0031] The condensation recovery device condenses the evaporated material discharged from the ...

Embodiment 2

[0040] A sludge dehydration drying incineration method, such as image 3 shown, including the following steps:

[0041] (1) Sludge conditioning: the sludge is discharged into the sludge conditioning device 1, and the condensed hot water and other heat exchange wastewater discharged from the condensation recovery device are sent to the sludge conditioning device 1, and the sludge is diluted and increased. The temperature is 30℃~70℃ after the temperature increase. The filter press layer can also realize the pretreatment and removal of the cooling turbid liquid in the drying section with high SS and ammonia nitrogen, without the need for separate dosing treatment. This section can save water and medicine. ,Improve efficiency;

[0042] (2) Sludge dewatering: dewatering the diluted and warmed sludge through the sludge deep dewatering device to form a mud cake, the mud cake has a moisture content of 50% to 60% and a temperature of 30°C to 60°C;

[0043] (3) Sludge drying: the mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com