Ice-cold compound material and ice-cold slice prepared from ice-cold compound material

A composite material and ice-cooling technology, which is applied in the field of ice-cooled composite materials and sheets, can solve the problems of reducing the working efficiency and high cost of heat dissipation sheets, and achieve the effects of reducing production costs, cheap materials, and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

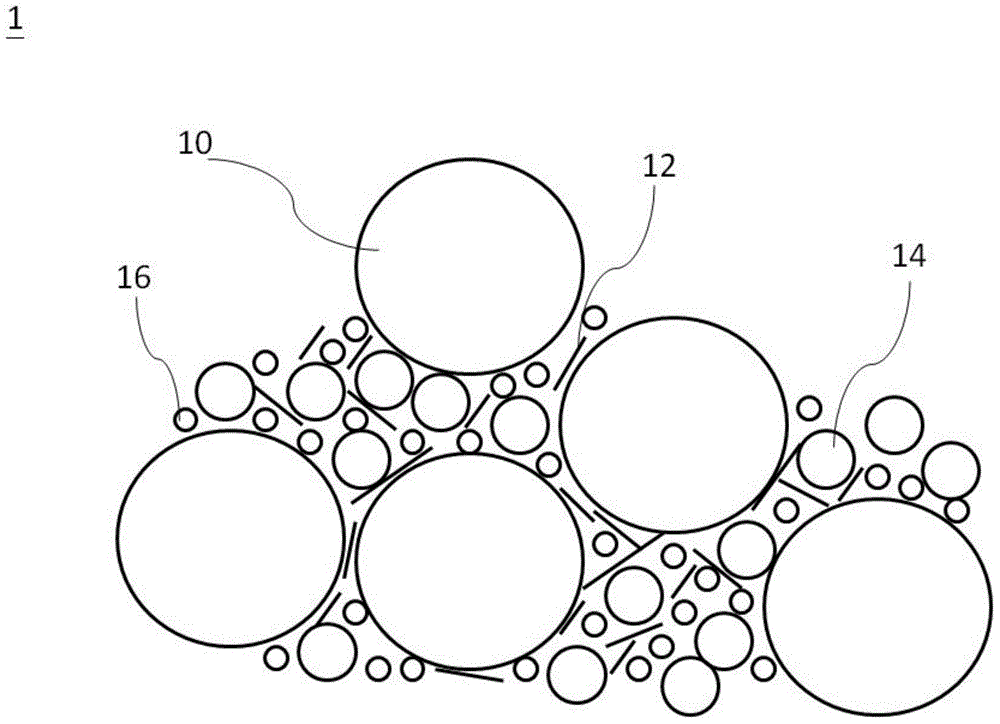

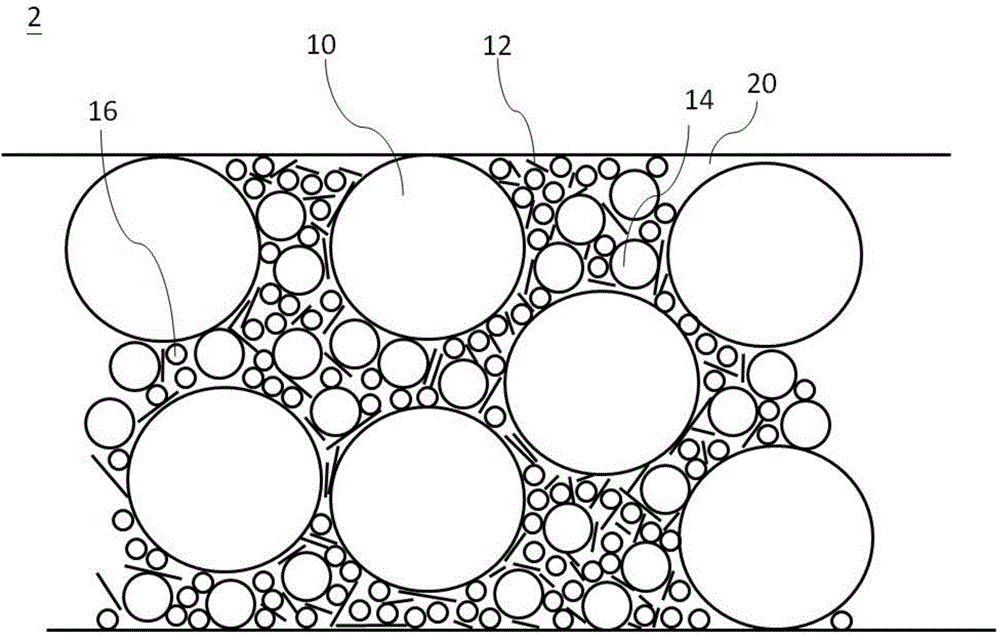

[0021] The present invention discloses an ice-cooling sheet and an ice-cooling composite material made of such a sheet. The following text is only used to schematically express the relevant characteristics of the composite ice-cooling powder of the present invention, and does not limit the technical content to be protected by the present invention. The scope is described first.

[0022] Polyurethane (PU) is a commonly used industrial polymer, and there are other derivative polymers, one of which is thermoplastic polyurethane (TPU); the commercial form of TPU is usually granular, and its thermoplasticity is good, suitable for repeated processing , the processing methods can be: injection, extrusion, calendering, blow molding, compression molding, etc. It is a recyclable and environmentally friendly plastic elastomer. With its thermoplasticity, it can melt and produce viscosity when heated. Adhesives are used.

[0023] Graphene is a two-dimensional honeycomb planar lattice stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap