Granite-imitating rock chip paint and preparation method thereof

A technology of imitating granite and rock flake paint, applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problems of unstable color difference and self-weight of batches of granite resources, and achieve good storage stability and saving. The effect of limited resources and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

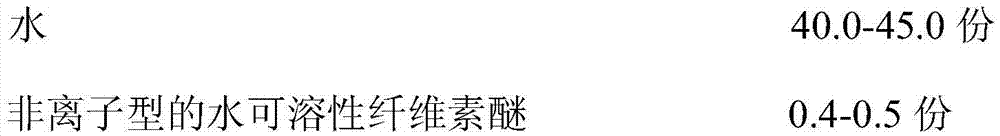

[0037] A kind of imitation granite flake paint, it is formulated by the following components of weight ratio:

[0038]

[0039] The imitation granite rock flake paint comprises the following steps carried out in sequence:

[0040] ①Under stirring at a rotating speed of 700r / min, add non-ionic water-soluble cellulose ether and natural bentonite to the water, then stir for 4 minutes, and then add 2-amino -The aqueous solution of 2-methyl-1-propanol, then continue to stir 8min;

[0041] ②Under stirring at a speed of 720r / min, add acrylate copolymer emulsion, oil-based defoamer, alcohol ester dodeca, propylene glycol and divalent metal salt-stabilized Cathone fungicides to the mixture prepared in step ① in sequence Afterwards, continue for 4min, then add nonionic polyurethane rheology modifier, then continue to stir for 8min;

[0042] ③Under stirring at a speed of 800r / min, slowly add the mixture of colorful rock flakes of different sizes to the mixture prepared in step ②, an...

Embodiment 2

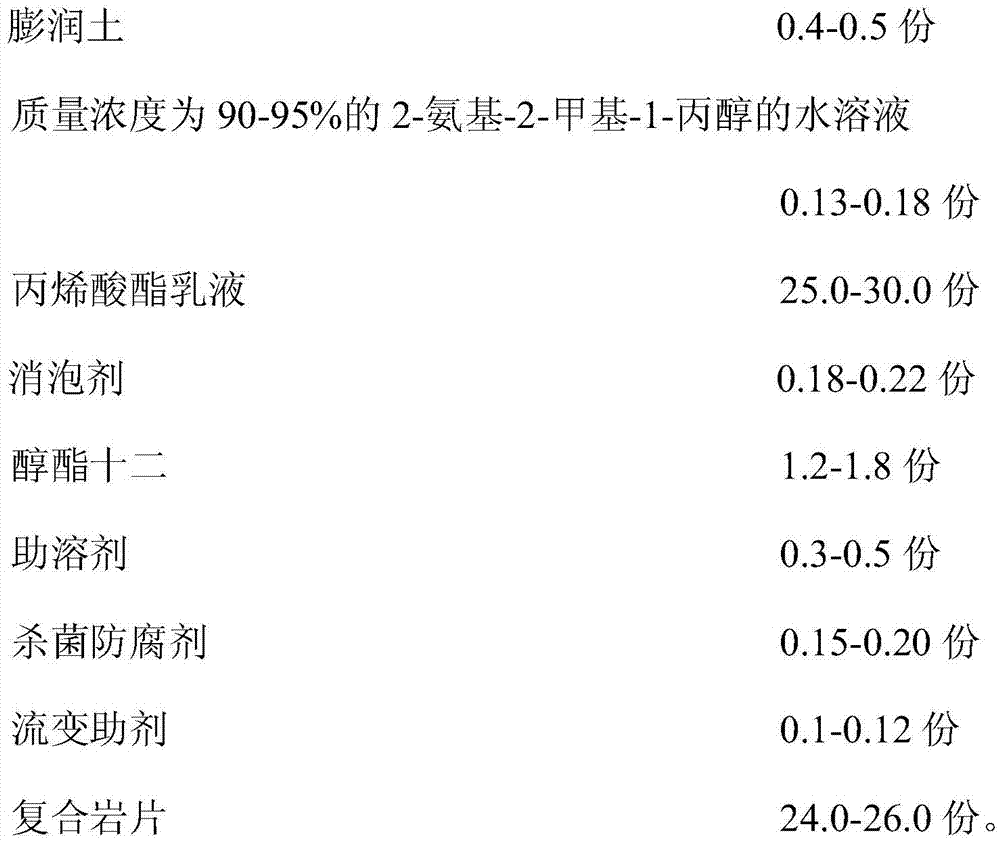

[0044] A kind of imitation granite flake paint, it is formulated by the following components of weight ratio:

[0045]

[0046] The imitation granite rock flake paint comprises the following steps carried out in sequence:

[0047] ①Under stirring at a rotating speed of 500r / min, add non-ionic water-soluble cellulose ether and artificially modified bentonite to the water, then stir for 5 minutes, and then add 2 -Aqueous solution of amino-2-methyl-1-propanol, then continue to stir for 10min;

[0048] ②Under stirring at a speed of 700r / min, add acrylate emulsion, silicone defoamer, alcohol ester twelve, co-solvent and bactericidal preservative to the mixture prepared in step ① in sequence, continue for 5 minutes, and then add fluid Add additives, and continue to stir for 5 minutes;

[0049] ③Under stirring at a rotating speed of 750r / min, slowly add the same size colorful rock flake mixture to the mixture prepared in step ②, and continue to stir thoroughly for 15 minutes to ...

Embodiment 3

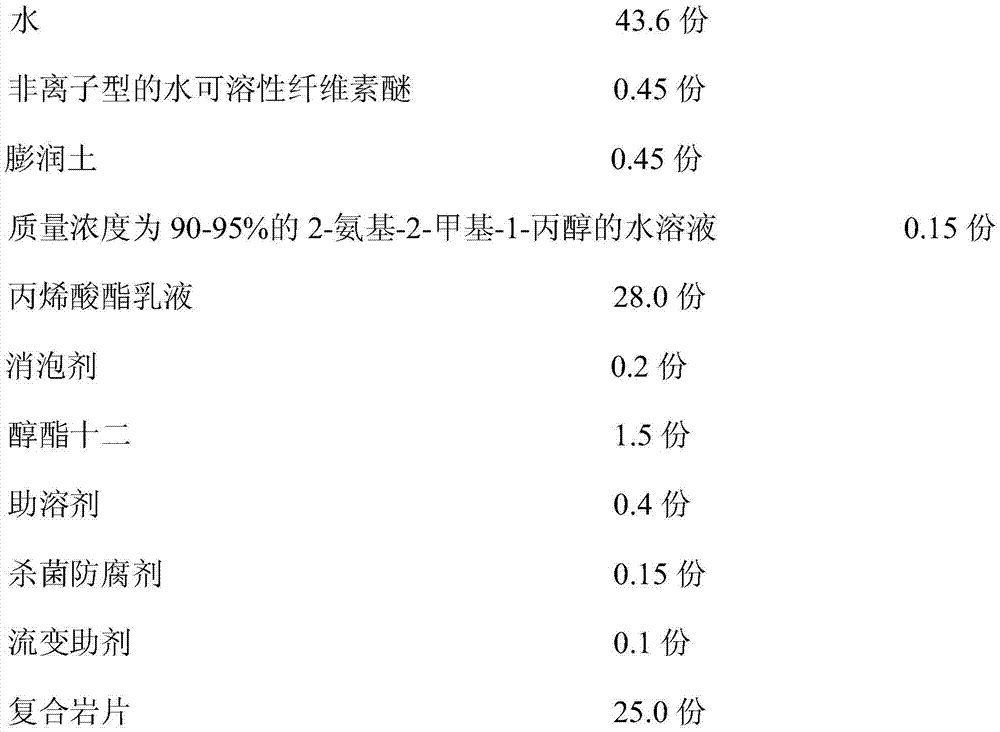

[0051] A kind of imitation granite flake paint, it is formulated by the following components of weight ratio:

[0052]

[0053] The imitation granite rock flake paint comprises the following steps carried out in sequence:

[0054] ①Under stirring at a rotating speed of 750r / min, add non-ionic water-soluble cellulose ether and bentonite to the water, and then stir for 3 minutes, then add 2-amino- The aqueous solution of 2-methyl-1-propanol, then continue to stir 5min;

[0055] ②Under stirring at a speed of 750r / min, add acrylate emulsion, emulsion type defoamer, alcohol ester twelve, co-solvent and bactericidal preservative to the mixture prepared in step ① in sequence, continue for another 3 minutes, and then add fluid Add additives, and continue to stir for 10 minutes;

[0056] ③Under stirring at a rotating speed of 1000r / min, slowly add composite rock flakes to the mixture prepared in step ②, and continue to stir thoroughly for 1 minute to obtain imitation granite rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com