Nonacid mud cake flushing agent, flushing liquid and flushing method

A non-acid, flushing fluid technology, applied in wellbore flushing, chemical instruments and methods, and earthwork drilling and production, can solve problems such as inability to wet and decompose mud cake, complex flushing fluid formula components, and pipe string corrosion, etc., to achieve Change the water wetting condition, good flushing effect, and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

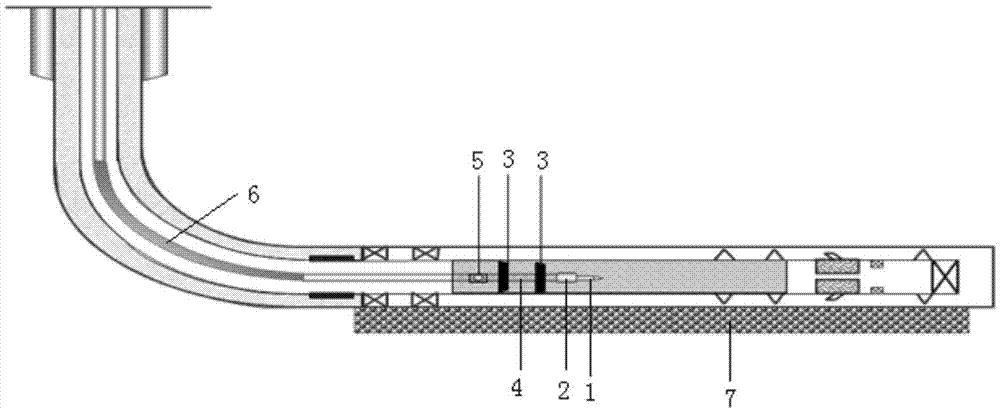

Image

Examples

Embodiment 1

[0026] The non-acidic mud cake flushing agent of this embodiment is composed of the following components in parts by mass: 50 parts of sodium tripolyphosphate, 10 parts of ammonium persulfate, and 3 parts of sodium dodecylbenzenesulfonate.

[0027] The non-acidic mud cake flushing solution of this embodiment is composed of the following components in mass percentage: 0.5% sodium tripolyphosphate, 0.1% ammonium persulfate, 0.03% sodium dodecylbenzenesulfonate, and the balance is water.

[0028] The preparation method of the above-mentioned non-acidic mud cake flushing solution is to disperse sodium tripolyphosphate, ammonium persulfate and sodium dodecylbenzenesulfonate in water, and stir evenly to obtain the product.

[0029] The flushing method of the present embodiment comprises the following steps:

[0030] 1) Lower the well flushing string to a distance of 50m from the top of the screen pipe, and perform the first backwashing and slurry replacement with a displacement of n...

Embodiment 2

[0033] The non-acid mud cake flushing agent of this embodiment is composed of the following components by mass: 40 parts of sodium tripolyphosphate, 10 parts of ammonium persulfate, and 5 parts of sodium dodecylbenzenesulfonate.

[0034] The non-acid mud cake flushing liquid of this embodiment is composed of the following components in mass percentage: 0.4% sodium tripolyphosphate, 0.1% ammonium persulfate, 0.05% sodium dodecylbenzenesulfonate, and the balance is water.

[0035] The preparation method of the above-mentioned non-acidic mud cake flushing solution is to disperse sodium tripolyphosphate, ammonium persulfate and sodium dodecylbenzenesulfonate in water, and stir evenly to obtain the product.

[0036] The flushing method of the present embodiment comprises the following steps:

[0037] 1) Lower the well flushing string to a distance of 50m from the top of the screen pipe, and perform the first backwashing and slurry replacement with a displacement of not less than 45...

Embodiment 3

[0040] The non-acid mud cake flushing agent of this embodiment is composed of the following components by mass: 45 parts of sodium tripolyphosphate, 10 parts of ammonium persulfate, and 4 parts of sodium dodecylbenzenesulfonate.

[0041] The non-acid mud cake flushing liquid of this embodiment is composed of the following components in mass percentage: 0.45% sodium tripolyphosphate, 0.1% ammonium persulfate, 0.04% sodium dodecylbenzenesulfonate, and the balance is water.

[0042] The preparation method of the above-mentioned non-acidic mud cake flushing solution is to disperse sodium tripolyphosphate, ammonium persulfate and sodium dodecylbenzenesulfonate in water, and stir evenly to obtain the product.

[0043] The flushing method of the present embodiment comprises the following steps:

[0044] 1) Lower the well flushing string to a distance of 50m from the top of the screen pipe, and perform the first backwashing and slurry replacement with a displacement of not less than 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com