Coal pyrolysis and gasification combined production method

A technology of joint production and coal pyrolysis, applied in the field of coal gasification, can solve problems such as low carbon conversion rate, and achieve the effects of improving carbon conversion rate, system optimization, and solving ash discharge problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

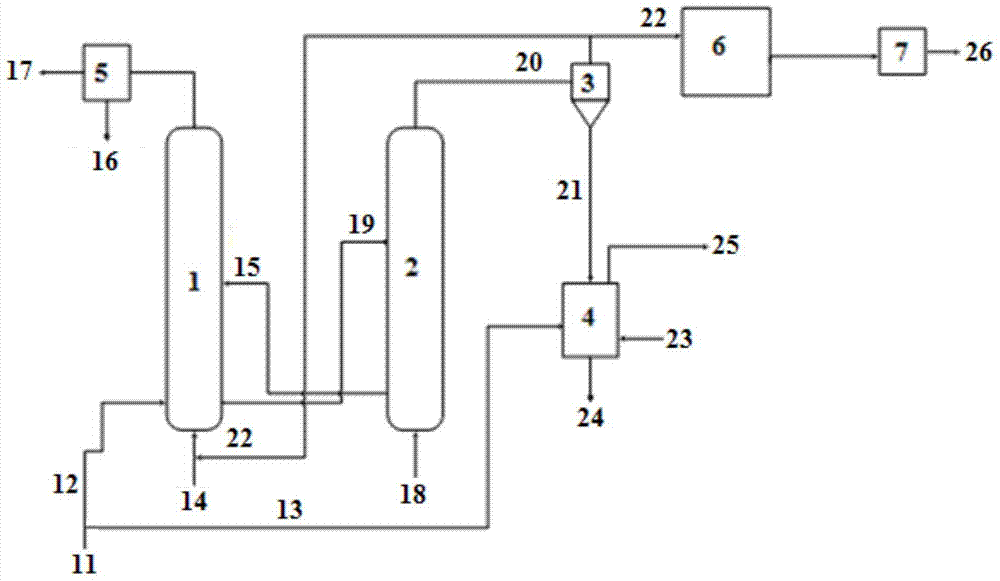

[0052] According to a preferred embodiment of the present invention, the process flow chart of the joint production method of coal pyrolysis and gasification is as follows figure 1 shown. Specifically, the joint production method of coal pyrolysis and gasification includes:

[0053] (1) Grinding the raw coal 11 to below 6 mm, and separating it into coarse coal powder 12 and fine coal powder 13;

[0054] (2) Coarse pulverized coal 12 is injected into the fluidized bed pyrolysis furnace 1 for pyrolysis, and superheated steam 14 and optionally product gas 22 from the subsequent fluidized bed gasification furnace 2 are heated from the fluidized bed The bottom of the pyrolysis furnace 1 is injected as a part of the heat source and fluidization gas, and at the same time, the high-temperature semi-coke 15 from the subsequent fluidized bed gasification furnace 2 is injected from the middle of the fluidized bed pyrolysis furnace 1 as another part of the heat source. The outlet gas te...

Embodiment 1

[0066] This example is used to illustrate the joint production method of coal pyrolysis and gasification provided by the present invention.

[0067] Such as figure 1As shown, the raw coal is ground by a coal mill and sieved to obtain coarse coal powder with a particle size of 0.15-3 mm and fine coal powder with a particle size of less than 0.15 mm. The coarse coal powder is injected into the fluidized bed pyrolysis furnace 1 at 30 kg / h for pyrolysis, the operating temperature is 550° C., and the operating pressure is 0.1 MPa. The heat required by the pyrolysis furnace mainly comes from the high-temperature semi-coke (950°C) of the fluidized bed gasifier 2, and part of the product gas (950°C) from the fluidized bed gasifier 2 is injected into the pyrolysis furnace 1 to make the heat The furnace 1 realizes fluidized operation. The outlet temperature of the pyrolysis furnace is 450°C, and the coal tar carried in it is separated from the pyrolysis gas after being washed with wat...

Embodiment 2

[0079] This example is used to illustrate the joint production method of coal pyrolysis and gasification provided by the present invention.

[0080] Such as figure 1 As shown, the raw coal is ground by a coal mill and sieved to obtain coarse coal powder with a particle size of 0.15-3 mm and fine coal powder with a particle size of less than 0.15 mm. The coarse coal powder is injected into the fluidized bed pyrolysis furnace 1 at 30 kg / h for pyrolysis, the operating temperature is 600° C., and the operating pressure is 1.2 MPa. The heat required by the pyrolysis furnace mainly comes from the high-temperature semi-coke (980°C) of the fluidized bed gasifier 2, and part of the product gas (980°C) from the fluidized bed gasifier 2 is injected into the pyrolysis furnace 1 to make the heat The furnace 1 realizes fluidized operation. The outlet temperature of the pyrolysis furnace is 500°C, and the coal tar carried in it is separated from the pyrolysis gas after being washed with wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com