Refitting method and structure for upper joint assembly

A component structure and component technology, which is applied in earthwork drilling, mechanical equipment, construction, etc., can solve problems such as high surface roughness and coaxiality, difficulty in processing parts to meet design requirements, and high processing difficulty, so as to reduce Difficulty of processing, meeting the requirements of use, and improving the effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

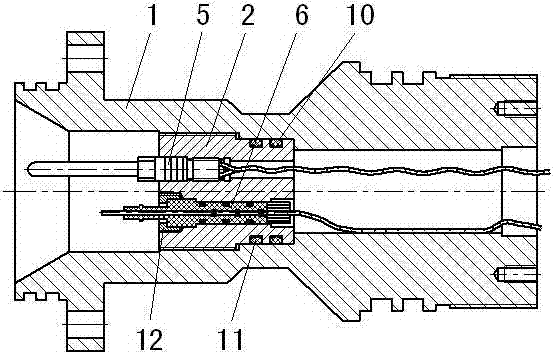

[0022] This example is an improvement on existing technologies, such as Figure 4 shown by Figure 4 It can be seen that the temperature probe installation hole 3 and the sealing plug installation hole 4 are processed in the middle section of the existing joint 13 as a whole. Since these two holes are located deep, the requirements for surface roughness and coaxiality are high, and the processing is very difficult. The processing quality of parts is difficult to meet the design requirements. The pass rate in processing is low.

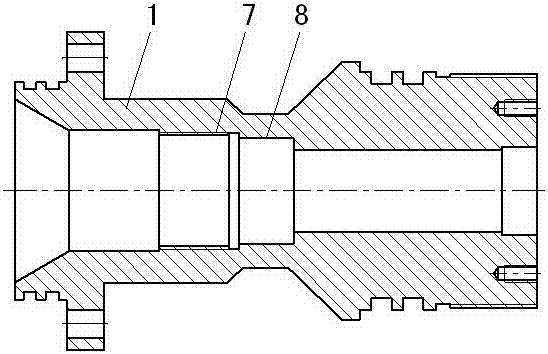

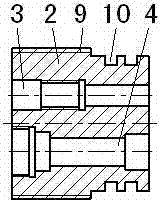

[0023] In order to reduce the processing difficulty of the parts, in this example, the existing overall joint 13 is split into such figure 2 The connector body shown in 1 and image 3 The shown plug 2; the plug 2 is processed with a mounting hole for installing the temperature probe 5 and the sealing plug 6, and the outer circle of the plug 2 is processed with an external thread and a sealing groove for connecting with the inner hole of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com