Semiconductor structure forming method

A semiconductor and conductive layer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as differences in electrical properties of conductive plugs, unstable electrical properties of conductive films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

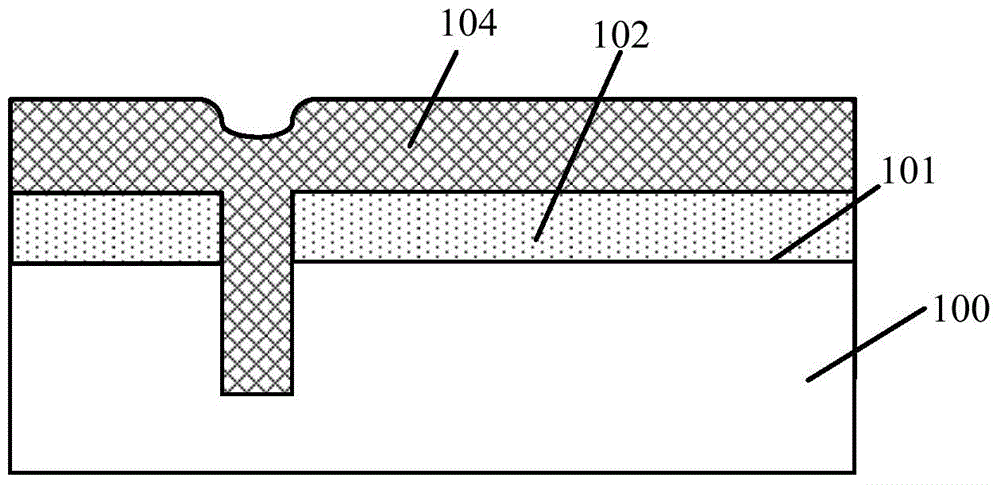

[0037] As described in the prior art, due to the unstable electrical properties of the formed conductive film, the electrical properties of the conductive plugs formed by the conductive film are different.

[0038] After research, it is found that due to the limitation of the physical vapor deposition process, the electrical thickness of the conductive film formed on the surface of different substrates is different, resulting in differences in the electrical properties of the conductive plug formed by the conductive film, resulting in differences between the substrates. The electrical connection performance is not stable.

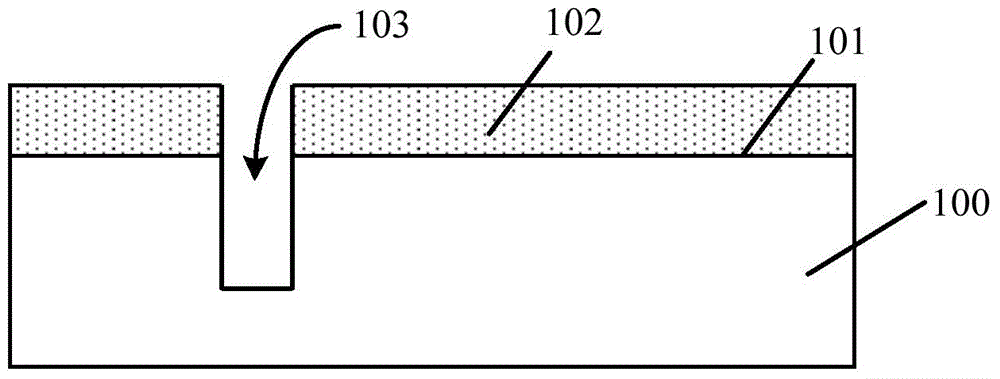

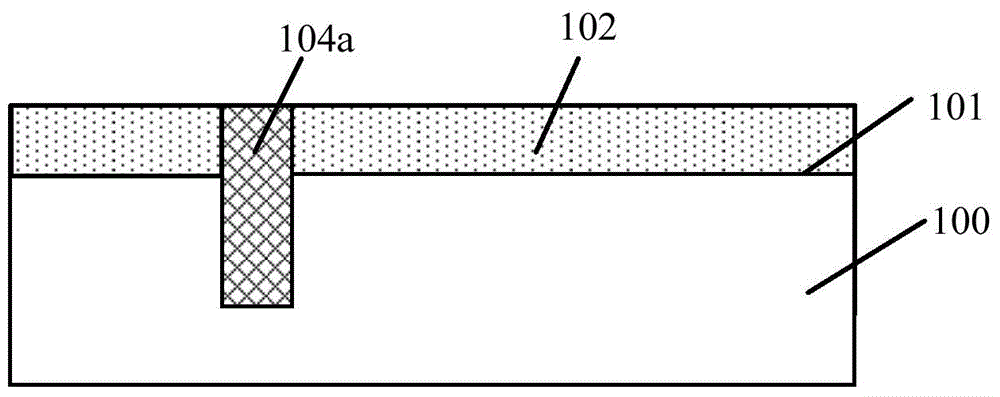

[0039] Please continue to refer Figure 1 to Figure 3 , since the device layer 102 is formed on the surface of the substrate 100 before the conductive film 104 is formed, in order to avoid damage to the device layer 102 caused by the process of forming the conductive film 104, the temperature of the physical vapor deposition process needs to be The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com