Lithium ion liquid flow cell reactor

A liquid flow battery and lithium ion technology, applied in the direction of regenerative fuel cells, fuel cell components, etc., can solve problems such as inconsistent flow of electrode suspensions, deterioration of battery performance, overcharging or overdischarging of battery cells, and avoid disadvantages Influencing, improving safety, good diversion and confluence effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

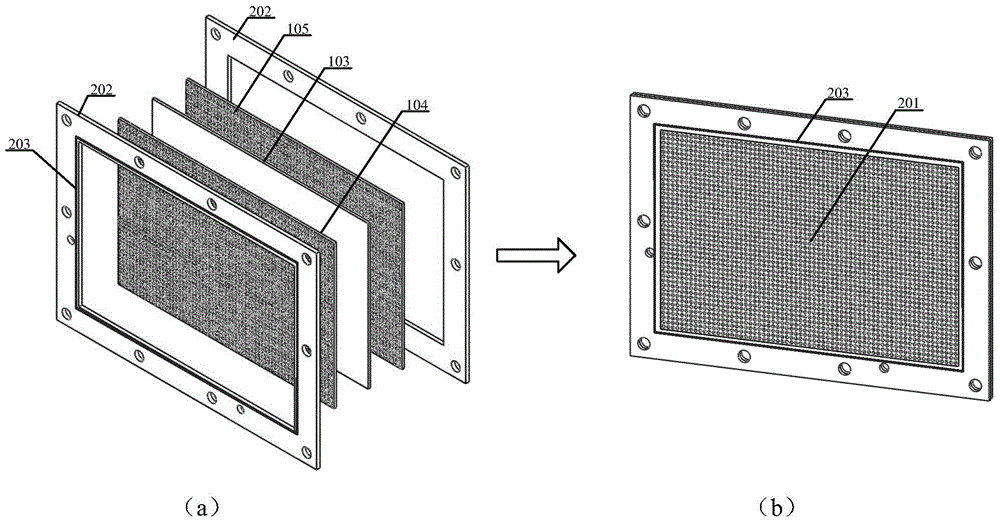

[0050] This embodiment provides a lithium ion flow battery reactor 601 , which includes a bipolar separator 201 , a positive electrode conductor 301 a , a negative electrode conductor 301 b , an upper cover plate 602 , and a lower cover plate 603 . Among them, several bipolar separators 201, positive electrode conductors 301a, and negative electrode conductors 301b are alternately stacked up and down to form a battery cell group 501, and the lithium ion flow battery reactor 601 follows the upper cover plate 801—the battery cell group 601— The lower cover plate 802 is arranged in a manner, sealed by a seal, and compressed by a fastener. The respective battery cells 501 are connected in parallel by metal wires.

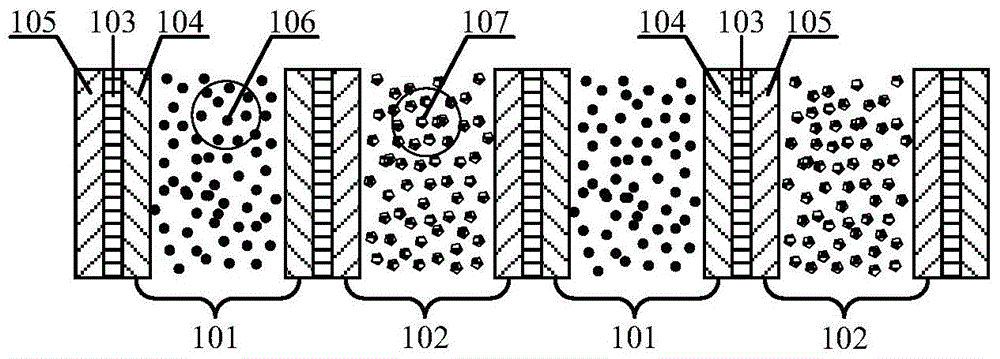

[0051] In this embodiment, the bipolar separator 201 is composed of the isolation layer 103 and the positive electrode current collector layer 104 and the negative electrode current collector layer 105 which are located on both sides of the isolation layer and are in cl...

Embodiment 2

[0058] In this embodiment, the bipolar separator 201 is composed of a separation layer 103 and a positive current collector layer 104 and a negative current collector layer 105 located on both sides of the separation layer 103 and in close contact with the separation layer 103 . Wherein, the isolation layer 103 is an electronic insulating layer that isolates the positive and negative current collector layers and prevents the electrons in the battery from freely passing through, but the lithium ions in the electrolyte or gel electrolyte can freely pass through, and its thickness is 0.5 mm. Both the positive electrode current collecting layer 104 and the negative electrode current collecting layer 105 are ion / electron mixed conductive layers through which both lithium ions and electrons can pass freely, and both have a thickness of 0.5 mm. The positive electrode current collector layer 104 and the negative electrode current collector layer 105 are placed on both sides of the isol...

Embodiment 3

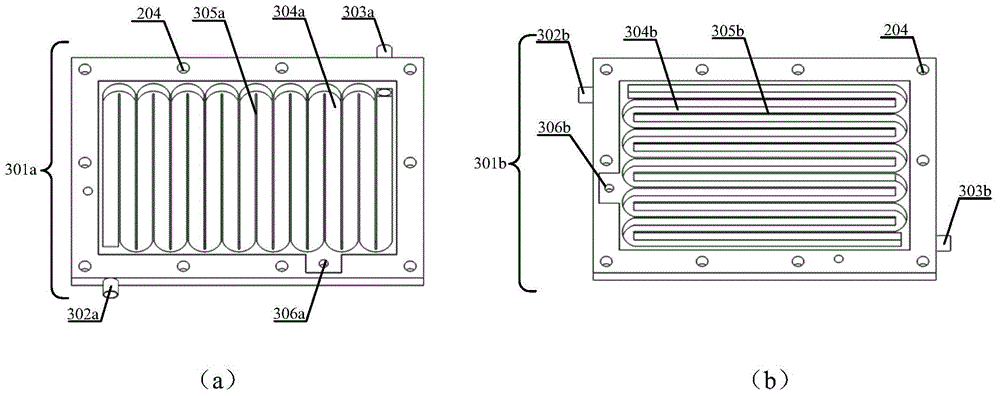

[0068] In this embodiment, the positive electrode flow channel ridge 305a is located in the positive electrode reaction chamber and can resist oxidation reaction. The material is one or more of aluminum, alloy aluminum, stainless steel, silver, tin or titanium, preferably aluminum; 305b is located in the negative electrode reaction chamber and is resistant to reduction reaction. The material is one or more of copper, stainless steel, nickel, titanium, silver, tin, tin-plated copper, nickel-plated copper, and silver-plated copper, preferably nickel-plated stainless steel;

[0069] Alternatively, the positive electrode runner ridge 305a and the negative electrode runner ridge 305b are electronically conductive films coated on the surface of organic fiber materials; the organic fiber materials include polyester fibers, nylon fibers, natural cotton, aramid, nylon, polypropylene, Polyethylene, polytetrafluoroethylene and other organic substances with good electrolyte resistance; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com