A kind of insecticidal and bactericidal composition containing methoxyfenozide

An insecticidal, bactericidal, and insecticidal fungicide technology is applied in the application field of preventing and treating Diploxinus chinensis, rice leaf roller and rice blast, and can solve the problems of weak disease resistance, narrow control spectrum, and only protective effect, etc. To achieve personal and environmental safety, improve the effect of prevention and control, and prolong the effect of the validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

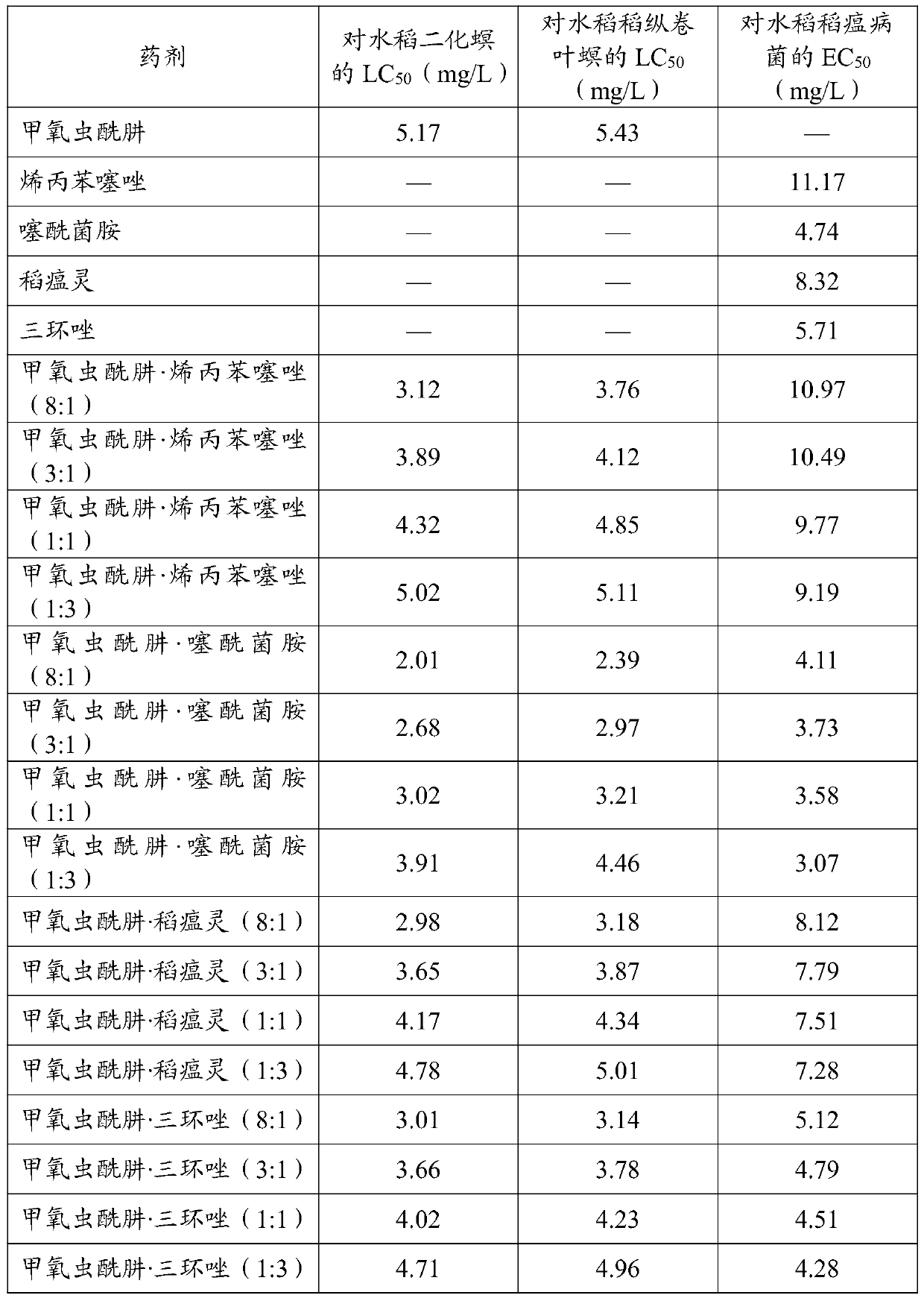

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of 18% methoxyfenozide allylbenthiazole emulsifiable concentrate (active ingredient ratio 8:1)

[0050] Weigh 4% Nongru 500#, 2% Nongru 600#, 3% Nongru 2201#, 1% triphenyl phosphite, 2% dimethyl sulfoxide, and cyclohexanone to 100% by weight. The above raw materials are mixed, stirred and dissolved, and then 16% methoxyfenozide and 2% allylbendazole are added, and after stirring and dissolving completely, 18% methoxyfenozide-albendazole emulsifiable concentrate is obtained.

Embodiment 2

[0051] Example 2: Preparation of 8% methoxyfenozide allylbenthiazole suspension (active ingredient 3:1)

[0052] Weigh 6% methoxyfenozide, 2% allylbenzothiazole, 2.5% tristyrylphenol polyoxyethylene ether phosphate, 1.5% diffusing agent NNO, 4% TERSPERSE4894 (produced by Huntsman, USA), 10% cyclohexanone, 3.5% Span-60#, 3.5% Tween-60#, 1% TERSPERSE2500 (produced by Huntsman, USA), 2% magnesium aluminum silicate, 0.2% xanthan gum, 5% ethyl alcohol Diol, 1% epichlorohydrin, 0.3% benzoic acid, 0.5% silicone defoamer (trade name: s-29 produced by Nanjing Sixin Applied Chemicals Co., Ltd.), and deionized water are added to 100% by weight. The operation steps are as follows: According to the above ratio, mix and shear the dispersant, wetting agent, defoamer, water, etc. evenly, then add methoxyfenozide and allylbenzothiazole, and grind with a sand mill to obtain 8% Methoxyfenozide Allylbenzothiazole Suspension Concentrate.

Embodiment 3

[0053] Example 3: Preparation of 18% methoxyfenozide allylbenthiazole granule (active ingredient 8:1)

[0054] Weigh 16% methoxyfenozide, 2% allylbenzothiazole, 0.9% alkylnaphthalene sulfonate formaldehyde condensate, 2% polyvinyl alcohol, 1% sodium sulfate, 5% polyethylene glycol , 0.1% polyvinyl alcohol, kaolin as a carrier added to 100%. The above ingredients are kneaded with water, kneaded and shaped by a kneading granulator, and then the granules are dried in a fluidized bed to adjust the particle size to obtain 18% methoxyfenozide allylbenthiazole granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com