A solar chemical accident handling robot and working method

A technology of accident handling and solar energy, applied in the field of robots for chemical accident handling, can solve the problems of long cycle time, increase of secondary injuries of personnel, limited efficiency of power storage and collection, etc., and achieve the effect of strong adaptability to terrain and easy remote control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

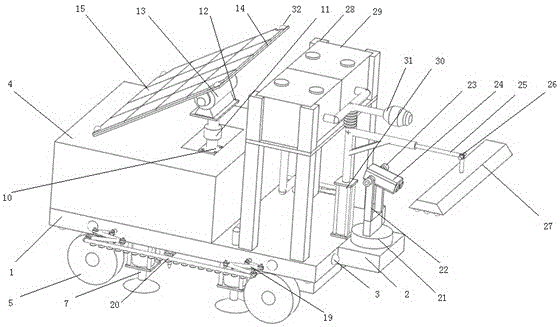

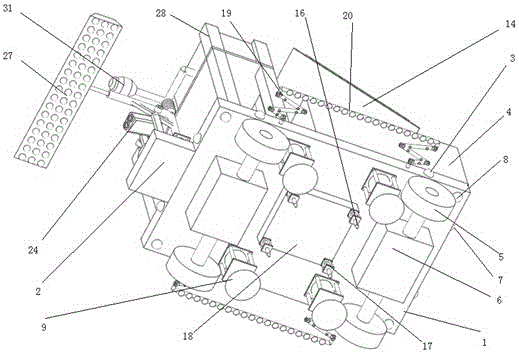

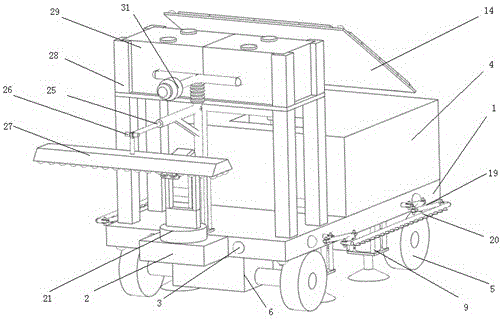

[0051] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0052] The invention provides a robot and working method for solar chemical accident treatment. The robot mainly includes supporting boards, moving wheels, chemical substance detection equipment, spraying equipment, multi-angle cameras, variable-angle solar panels and other equipment, which can be used according to corresponding The detection results and shooting results of the accident area are processed accordingly, the processing effect is good, the processing efficiency is high, and the variable angle solar panel is used for power supply, and the solar panel can change with the angle of light, and the solar energy absorption efficiency is high. long time.

[0053] As an embodiment of the present invention, the present invention provides a robot for handling solar chemical accidents, including a main support plate 1, a front support plate 2, a control box 4, wheels 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com