Acorn starch and preparation method thereof

A kind of technology of acorn starch and starch, applied in the field of acorn starch and its preparation, can solve the problems of poor comprehensive adsorption and desorption capacity, slow elution rate, etc., and achieve high starch content, less water consumption, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, preparation acorn starch

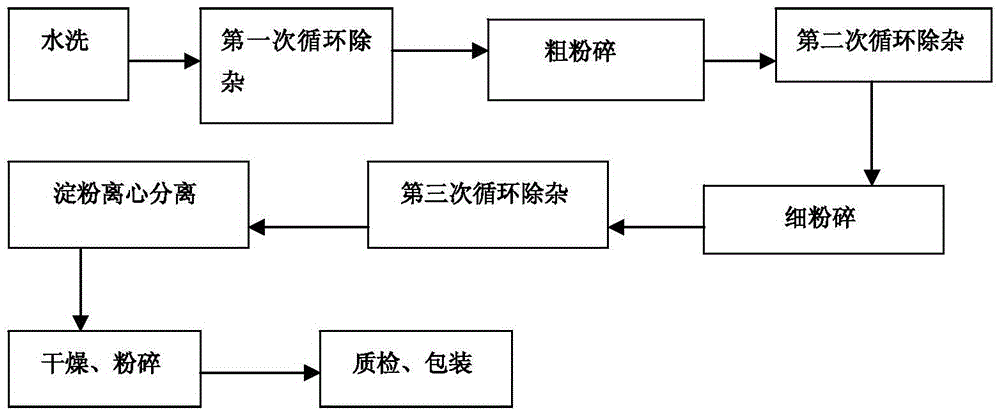

[0055] according to figure 1 Process flow chart shown in the preparation of acorn starch, wherein, the flow chart of the first to third cycle is as follows figure 2 As shown, the specific steps are as follows:

[0056] (1) Water washing: Take 50kg of acorn kernels and wash off the dust adhering to them with distilled water, remove impurities and residual acorn shells, seed coats, etc.

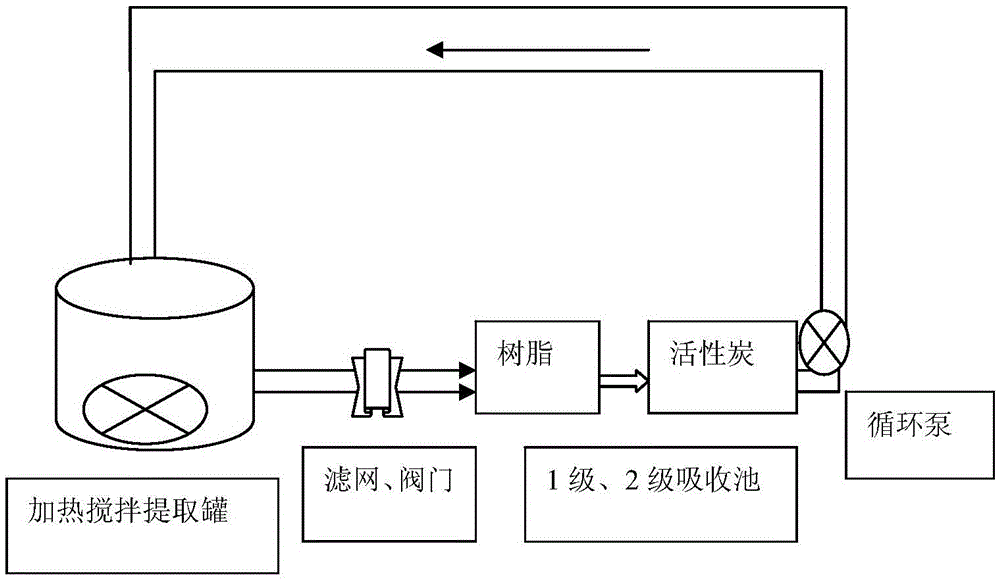

[0057] (2) Soaking and the first cycle of impurity removal: put 50kg of dry acorn kernels into the extraction tank at a ratio of 1:5 (kg:L) to hot water at 40°C for 6 hours, and then carry out The first cycle of impurity removal (hot water cycle-composite resin process treatment), the specific steps are as follows:

[0058] The acorn kernels and soaked water are further stirred and extracted in the extraction tank, the water-soluble starch and impurities in the acorn kernels are extracted into the water, and after being filtered by the filter ...

Embodiment 2

[0074] Embodiment 2, preparation acorn starch

[0075] according to figure 1 Process flow chart shown in the preparation of acorn starch, wherein, the flow chart of the first to third cycle is as follows figure 2 As shown, the specific steps are as follows:

[0076] (1) Water washing: Take 50kg of acorn kernels and wash off the dust adhering to them with distilled water, remove impurities and residual acorn shells, seed coats, etc.

[0077] (2) Soaking and the first cycle of impurity removal: Add 50kg of dry acorn kernels to water in a mass-volume ratio (kg:L) of 1:10 and soak in hot water at 40°C for 4 hours in the extraction tank. Then carry out the first cycle of impurity removal (hot water cycle-composite resin process), the specific steps are as follows:

[0078] The acorn kernels and soaked water are further stirred and extracted in the extraction tank, the water-soluble starch and impurities in the acorn kernels are extracted into the water, and after being filtered...

Embodiment 3

[0094] Embodiment 3, the character of acorn starch and quality detection

[0095] (1) Granular morphology and starch content of acorn starch

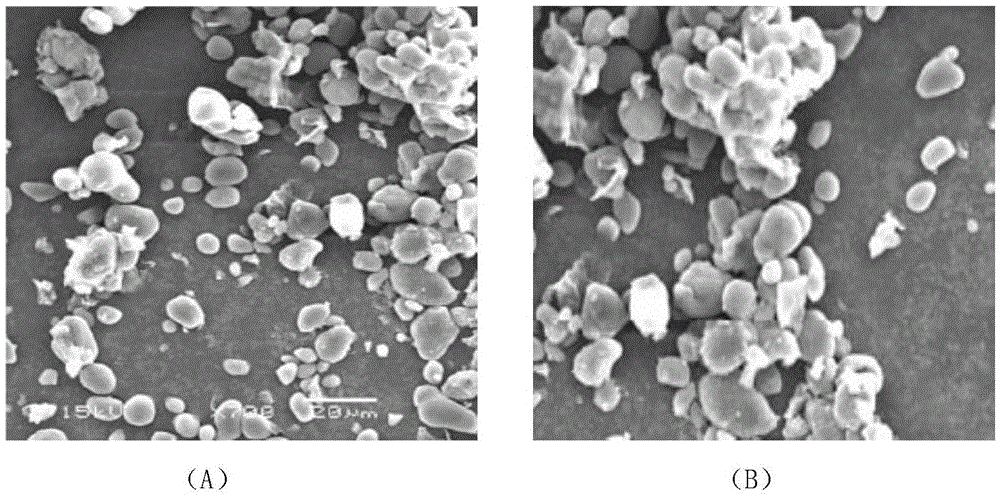

[0096] Use SEM (KYKY-EM3900) to observe the acorn starch prepared in Example 1 and Example 2 at a magnification of 400-1000, and photograph a representative starch granule morphology, such as image 3 As shown, the morphology of starch granules in Example 1 and Example 2 is basically the same. The results showed that: acorn starch was oval or spherical, which was related to its amylose content.

[0097] Detect the quality starch and total starch content in the acorn starch that embodiment 1, 2 make, the result shows: the amylose content of acorn starch is respectively 29.78%, 29.66%, and total starch content is respectively 90.24%, 90.45%, the detection of amylose content is based on GB / T15683-2008, and the detection of total starch content is based on GB / T20378-2006.

[0098] (2) Solubility and swelling of acorn starch

[0099] Wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com