Polypropylene/polyethylene/wood fiber composite and preparation method thereof

A composite material and wood fiber technology, which is applied in the field of low-cost toughened polypropylene composite material and its preparation, can solve the problems of high cost, unfavorable popularization and use of polypropylene, complicated process, etc., and achieves improved environmental protection performance and reduced preparation cost. , the effect of rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

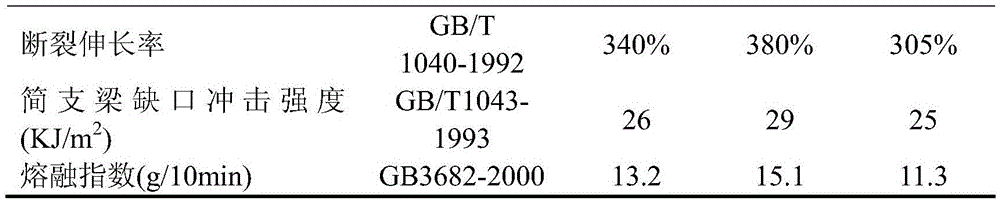

Embodiment 1

[0024] The preparation method of the multi-component composite modified polypropylene composite material:

[0025] (1) The composition of raw materials for preparing composite materials is as follows, by mass fraction: 40% polypropylene, 28% polyethylene, 20% wood fiber, 1.5% lubricant, 0.5% antioxidant, 10% compatibilizer, wherein, wood The fibers are treated with a silane coupling agent.

[0026] The polypropylene used therein is a copolymerized polypropylene (ethylene propylene copolymer).

[0027] The polyethylene used therein is low density polyethylene (LDPE).

[0028] The process of using a silane coupling agent to process wood fiber is as follows: the untreated wood fiber with a particle size of 120 meshes was baked at 100°C for 3 hours, then placed in a high-speed mixer, and the temperature in the high-speed mixer was maintained at 100-120°C, prepare the silane coupling agent KH-550 into a solution (by mass fraction: silane coupling agent 20%, ethanol 60%, deionized...

Embodiment 2

[0036] The preparation method of the multi-component composite modified polypropylene composite material:

[0037] (1) The composition of raw materials for preparing composite materials is as follows, by mass fraction: 45% polypropylene, 30% polyethylene, 15% wood fiber, 1% lubricant, 0.5% antioxidant, 8.5% compatibilizer, wherein, wood The fibers are treated with a silane coupling agent.

[0038] The polypropylene used therein is isotactic polypropylene.

[0039] The polyethylene used therein is linear low density polyethylene (LLDPE).

[0040] The process of using silane coupling agent to process wood fiber is as follows: the untreated wood fiber with a particle size of 150 meshes was baked at 100°C for 3 hours, then placed in a high-speed mixer, and the temperature in the high-speed mixer was maintained at 100~120℃, prepare the silane coupling agent KH-560 into a solution (by mass fraction: silane coupling agent 20%, ethanol 60%, deionized water 20%), and use a sprayer to...

Embodiment 3

[0048] The preparation method of the multi-component composite modified polypropylene composite material:

[0049] (1) The composition of raw materials for preparing composite materials is as follows, by mass fraction: 34% polypropylene, 34% polyethylene, 23% wood fiber, 1% lubricant, 1% antioxidant, 7% compatibilizer, wherein, wood The fibers are treated with a titanate coupling agent.

[0050] The polypropylene used therein is atactic polypropylene.

[0051] The polyethylene used therein is high density polyethylene (HDPE).

[0052] The process of using titanate coupling agent to treat wood fiber is as follows: bake untreated wood fiber with a particle size of 100 mesh at 100°C for 3 hours, then place it in a high-speed mixer, and keep it in the high-speed mixer. The temperature is 100 ~ 120 ℃, the titanate coupling agent TC-POT is prepared into a solution (by mass fraction: titanate coupling agent 20%, ethanol 60%, deionized water 20%), and use The sprayer sprays the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com